Inspection Robots: A Comprehensive Guide to Advanced Industrial Inspections

In today’s fast-evolving industrial landscape, ensuring the safety, efficiency, and reliability of operations is paramount. This has led to the rise of inspection robots, which are transforming how industries conduct inspections. These advanced machines offer unparalleled precision and efficiency, minimizing human risk and maximizing productivity.

In this comprehensive guide, we’ll delve deep into the world of inspection robots, exploring how they work, their applications across industries, and why they are critical to the future of industrial inspections.

By the end of this article, you’ll understand the importance of inspection robots, the technological advancements they bring, and how they can optimize your industrial processes.

Table of Contents

What Are Inspection Robots?

Inspection robots are specialized machines equipped with advanced sensors, cameras, and artificial intelligence (AI) designed to inspect, analyze, and monitor industrial environments. These robots can navigate through complex, dangerous, or hard-to-reach areas, providing detailed information in real-time.

Key Features of Inspection Robots:

- Advanced Sensors: Equipped with thermal, infrared, and ultrasonic sensors to detect faults and irregularities.

- Artificial Intelligence (AI): AI enables these robots to learn from data, recognize patterns, and predict potential failures.

- Autonomous Navigation: Many inspection robots can autonomously navigate complex environments without human intervention.

Why Are Inspection Robots Essential in Industrial Inspections?

Traditional inspection methods involve human inspectors, which can be risky and time-consuming. Inspection robots, on the other hand, enhance safety, reduce costs, and increase the accuracy of inspections. Below are some compelling reasons why inspection robots are vital:

- Enhanced Safety: Robots can enter hazardous environments like nuclear plants, oil refineries, and confined spaces, reducing the risk to human life.

- Increased Efficiency: Robots can operate 24/7 without fatigue, performing inspections faster and more thoroughly than humans.

- Cost Savings: By automating inspections, industries can save on labor costs and reduce downtime caused by manual inspections.

- Greater Accuracy: With precision sensors and AI, robots can detect even the smallest anomalies, improving the accuracy of inspections.

Types of Inspection Robots

Inspection robots come in various forms, each designed for specific industries and environments. Below are the most common types:

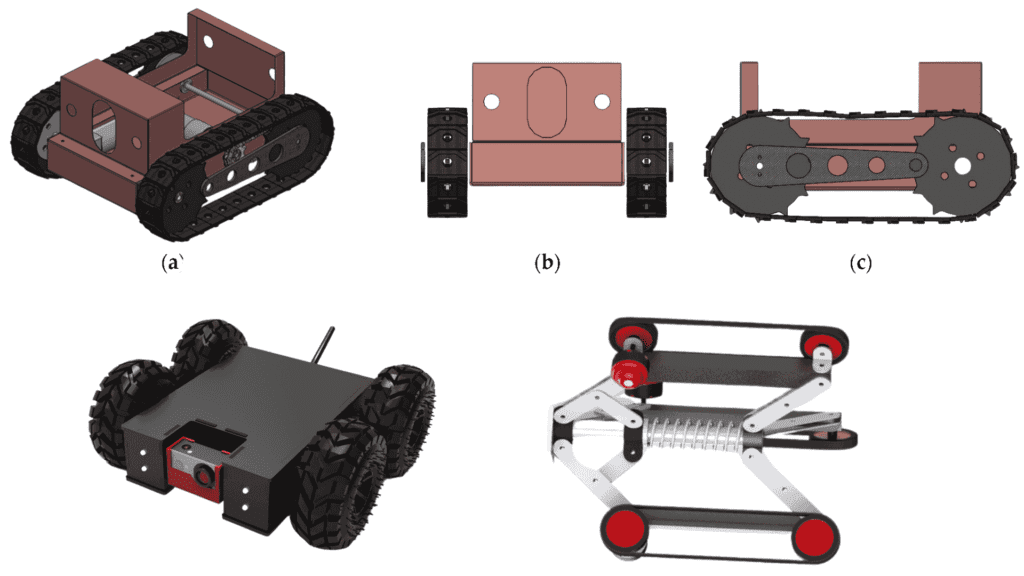

1. Crawling Robots

Crawling robots are designed to inspect pipelines, ducts, and other confined spaces. They can move through tight areas and provide detailed visual and sensory data.

Applications:

- Pipeline inspections

- HVAC duct inspections

- Sewage system analysis

2. Aerial Drones

Aerial drones are used for inspections in large, hard-to-reach areas such as power lines, wind turbines, and oil rigs. They are equipped with high-resolution cameras and can cover large areas quickly.

Applications:

- Power line and tower inspections

- Wind turbine maintenance

- Roof and building inspections

3. Underwater Robots (ROVs)

Remotely Operated Vehicles (ROVs) are used for underwater inspections, often in offshore oil and gas facilities, underwater pipelines, and marine structures. These robots are equipped with cameras and sonar to provide real-time data.

Applications:

- Offshore oil and gas platform inspections

- Underwater pipeline monitoring

- Bridge foundation inspections

4. Robotic Arms

Robotic arms are typically used in manufacturing plants for inspecting machinery, assembly lines, and other industrial equipment. They are known for their precision and flexibility.

Applications:

- Assembly line inspection

- Automotive manufacturing

- Aerospace component inspection

How Do Inspection Robots Work?

Inspection robots utilize a combination of sensors, cameras, AI, and navigation technologies to inspect industrial environments. Below is a breakdown of how these components function:

1. Sensors

Inspection robots are equipped with various sensors, including:

- Thermal Imaging: Detects temperature variations to identify overheating components.

- Ultrasonic Sensors: Used to measure thickness and detect cracks or corrosion.

- LIDAR: Creates 3D maps of environments to guide robots through complex spaces.

2. AI and Machine Learning

AI helps inspection robots analyze data collected from sensors, identifying patterns and predicting potential failures. Machine learning allows the robot to improve its inspection capabilities over time by learning from previous inspections.

3. Autonomous Navigation

Many inspection robots use LIDAR, GPS, or inertial navigation systems to move through environments without human control. This autonomy allows them to inspect areas that are difficult or dangerous for humans to reach.

Benefits of Using Inspection Robots

1. Increased Productivity

Inspection robots can work continuously, performing inspections faster than manual methods. This reduces downtime and increases overall productivity in industrial operations.

2. Reduced Human Error

Humans are prone to errors, especially when conducting inspections in challenging environments. Robots, however, operate with precision, reducing the likelihood of missed faults or inaccuracies.

3. Data-Driven Insights

Robots provide data in real-time, allowing industries to make informed decisions quickly. This is especially important for preventive maintenance, where early detection of faults can prevent costly breakdowns.

4. Improved Compliance

Many industries, such as oil and gas or nuclear energy, are subject to strict regulatory standards. Inspection robots help industries comply with these regulations by providing accurate, consistent data.

Applications of Inspection Robots in Various Industries

Inspection robots are used across multiple industries, each with unique needs and challenges. Below are some key sectors where these robots play a critical role:

1. Oil and Gas Industry

Inspection robots are used for pipeline inspections, offshore rig monitoring, and storage tank assessments. Their ability to operate in dangerous environments makes them invaluable for ensuring safety and compliance in the oil and gas sector.

2. Nuclear Power Plants

Nuclear plants require regular inspections to ensure safety. Robots can enter radioactive areas and inspect for signs of wear, corrosion, or other issues that could lead to accidents.

3. Manufacturing

In manufacturing plants, robotic arms and crawling robots inspect equipment, ensuring machines are operating correctly. Early detection of faults reduces the risk of breakdowns, saving time and costs.

4. Infrastructure Maintenance

Drones and crawling robots are used to inspect infrastructure like bridges, roads, and tunnels. They provide data on structural integrity, helping prevent accidents and costly repairs.

Future Trends in Inspection Robots

The future of inspection robots looks promising, with advancements in AI, machine learning, and sensor technology driving innovation. Some key trends include:

- Increased Autonomy: Future robots will rely less on human operators, becoming fully autonomous in their navigation and decision-making.

- Advanced AI Integration: AI will continue to evolve, allowing robots to analyze more complex data sets and provide deeper insights.

- Miniaturization: Inspection robots are becoming smaller and more agile, allowing them to access even more confined spaces for detailed inspections.

- Collaborative Robotics (Cobots): Collaborative robots, or cobots, are designed to work alongside human operators, enhancing safety and efficiency in inspections.

FAQs about inspection robots:

- What is an inspection robot?

An inspection robot is a specialized machine equipped with sensors, cameras, and AI to inspect industrial environments for faults, wear, or safety hazards. It is designed to improve accuracy, safety, and efficiency in industrial inspections. - How do inspection robots work?

Inspection robots use sensors (thermal, ultrasonic, etc.), cameras, and AI algorithms to analyze environments. They can navigate autonomously or semi-autonomously through confined or hazardous areas, collecting real-time data for detailed inspection. - Welding Robots: Revolutionizing Modern Manufacturing Welding Robots: Revolutionizing Modern Manufacturing

- The Ultimate Guide to Palletizers: Maximizing Efficiency in Industrial AutomationThe UltWelding Robots: Revolutionizing Modern Manufacturingimate Guide to Palletizers: Maximizing Efficiency in Industrial Automation

- What types of inspection robots are available?

Common types include crawling robots (for pipelines), aerial drones (for large or hard-to-reach areas), underwater robots (for marine and offshore facilities), and robotic arms (for manufacturing and assembly line inspections). - How much do inspection robots cost?

The cost of inspection robots varies widely depending on the complexity, size, and type of robot. Smaller models can start from $10,000, while more advanced robots with AI and multiple sensors can cost upwards of $100,000. - Are inspection robots autonomous?

Many inspection robots are fully or partially autonomous, meaning they can navigate environments and conduct inspections with minimal human intervention. Some, like drones or crawling robots, are remotely operated but equipped with autonomous navigation systems. - What are the limitations of inspection robots?

While they offer great benefits, inspection robots may face limitations such as high initial costs, maintenance requirements, limited battery life for extended inspections, and challenges in highly dynamic or obstructed environments. - How do inspection robots improve safety?

By taking over inspections in hazardous environments, such as inside nuclear power plants or underwater, robots prevent human inspectors from exposure to dangerous conditions. They also reduce risks in confined spaces or high-risk areas. - What advancements are being made in inspection robot technology?

Current advancements include AI integration for predictive maintenance, miniaturization for inspecting even smaller spaces, and enhanced sensor technologies, such as 3D mapping and machine learning algorithms for smarter data analysis. - How are inspection robots powered?

Most inspection robots are powered by rechargeable batteries, which provide the energy required for operation. The battery life varies by robot type and workload, with some capable of operating for several hours on a single charge. - Can inspection robots be used for preventive maintenance?

Yes, inspection robots play a critical role in preventive maintenance by detecting faults and potential issues early, allowing industries to address problems before they lead to costly breakdowns or failures. They provide real-time data to facilitate better decision-making.

Conclusion

Inspection robots are transforming the way industries conduct inspections, offering unprecedented efficiency, accuracy, and safety. As these robots continue to evolve with advancements in AI and sensor technology, their role in industrial inspections will only grow more critical.

Whether you’re in oil and gas, manufacturing, or infrastructure, integrating inspection robots into your operations can save time, reduce costs, and enhance safety.

Explore more in-depth resources and stay updated on the latest innovations in inspection technology at EngiTech. Let’s shape the future of industrial inspections together!