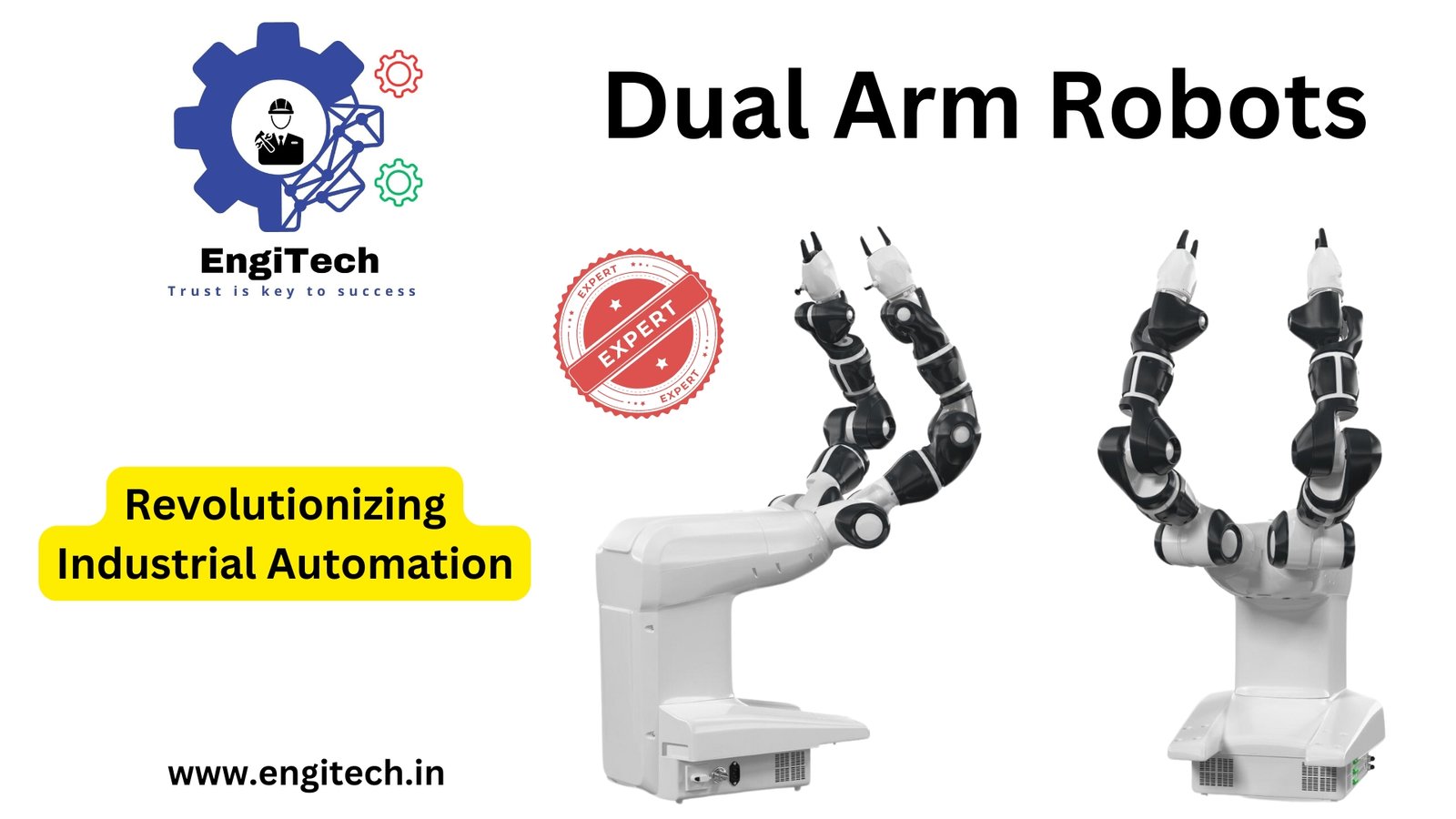

Dual Arm Robots: Revolutionizing Automation for Enhanced Efficiency and Precision

In today’s fast-evolving industrial landscape, automation is no longer a luxury; it’s a necessity. One of the most transformative innovations in robotics is the development of dual arm robots. These versatile machines are designed to mimic human-like coordination, offering unprecedented flexibility, precision, and efficiency. Whether it’s assembling complex electronics, managing delicate tasks in pharmaceutical labs, or optimizing workflows in manufacturing plants, dual arm robots are changing the game.

In this comprehensive guide, you’ll learn everything there is to know about dual arm robots—what they are, how they work, their applications, and why they’re critical to the future of industrial automation.

What You’ll Learn in This Guide:

- What dual arm robots are and how they work.

- The difference between dual arm robots and traditional robots.

- Applications of dual arm robots in various industries.

- Benefits and challenges of using dual arm collaborative robots.

- A look into specific models like ABB dual arm robots and dual arm SCARA robots.

- Future trends in dual arm robotics.

Introduction to Dual Arm Robots

Dual arm robots are robotic systems equipped with two arms that can work independently or collaboratively, much like human arms. Unlike single-arm robots that are limited in functionality and can handle one task at a time, dual arm robots are designed to manage complex operations simultaneously. This capability makes them ideal for tasks requiring high precision and dexterity, such as intricate assembly or handling fragile objects.

In industrial settings, dual arm robots excel in areas that previously required human intervention. Their ability to replicate human-like movements and multitask efficiently allows industries to enhance productivity, ensure consistent output, and reduce human error.

How Dual Arm Robots Work

At their core, dual arm robots are controlled by advanced algorithms and sensors that allow them to move with precision and accuracy. The robots are designed to:

- Coordinate Arm Movements: Just like humans, dual arm robots can manipulate objects using both arms. This coordination enables them to perform complex tasks, such as assembling small components or packing items efficiently.

- Adapt to New Tasks: Many modern dual arm robots, especially dual arm collaborative robots, are equipped with machine learning algorithms. This allows them to adapt to new tasks without requiring extensive reprogramming.

- Ensure Safety: Safety is paramount in any industrial setting. Dual arm collaborative robots, in particular, are designed to work safely alongside human workers, using sensors to detect nearby humans and avoid collisions.

Key Features of Dual Arm Robots

When comparing dual arm robots to other types of industrial robots, several distinct features set them apart:

- Multi-Tasking Capabilities: The dual arms can work together or independently, allowing for multitasking, which increases efficiency and reduces cycle times.

- Human-like Dexterity: The precision and range of motion offered by both arms allow dual arm robots to replicate human dexterity, handling tasks that require intricate movements.

- Versatility: Dual arm robots are not confined to a single task. They can be used for a range of functions, from heavy-duty industrial applications to delicate handling in labs or healthcare.

- Collaborative Design: Many modern dual arm robots are designed with collaboration in mind, meaning they can safely interact with human workers without requiring cages or physical barriers.

Applications of Dual Arm Robots

1. Manufacturing and Assembly

One of the most common uses of dual arm robots is in manufacturing and assembly lines. Whether it’s assembling complex products like electronics or automobiles, dual arm robots bring a level of precision and speed that surpasses traditional methods.

- Example: In electronics manufacturing, a dual arm SCARA robot can simultaneously hold and position a circuit board with one arm, while the other arm solders components in place, streamlining the process.

2. Packaging and Palletizing

Dual arm robots are also widely used in the packaging industry. Their ability to handle items of different sizes and weights, combined with their multitasking capabilities, makes them perfect for packaging products quickly and efficiently.

3. Healthcare and Pharmaceuticals

In the pharmaceutical industry, precision is crucial, and dual arm robots excel in environments where sterility and accuracy are non-negotiable. These robots are used for tasks like dispensing medications, handling delicate samples, and assembling medical devices.

4. Collaborative Workspaces

Dual arm collaborative robots are increasingly being used in environments where humans and robots work together. These robots are equipped with sensors that allow them to detect human presence, adjust their movements accordingly, and work safely alongside human counterparts.

The Rise of Dual Arm Collaborative Robots

Dual arm collaborative robots are specifically designed to work safely and efficiently alongside human workers. Unlike traditional industrial robots, which are often isolated to prevent accidents, collaborative robots—also known as cobots—have built-in safety features that allow for close human-robot interaction.

These robots excel in environments where space is limited or where human oversight is needed for quality control. Their ability to perform repetitive tasks while freeing up human workers to focus on higher-level problem-solving makes them invaluable assets in many industries.

Notable Models of Dual Arm Robots

1. ABB Dual Arm Robots

One of the leaders in dual arm robotics is ABB. Their ABB dual arm robots are known for their reliability, precision, and ease of use. ABB’s robots are often used in automotive and electronics manufacturing due to their high payload capacity and ability to handle complex tasks.

2. Dual Arm SCARA Robots

The dual arm SCARA robot is a specialized type of robot that is designed for high-speed, precision tasks, particularly in assembly and packaging industries. These robots excel in environments that require fast and accurate operations, such as semiconductor manufacturing or the food and beverage industry.

Challenges of Implementing Dual Arm Robots

While dual arm robots offer numerous advantages, they are not without challenges:

- Cost: Dual arm robots, especially high-end models like the ABB dual arm robot, can be expensive to purchase and maintain.

- Programming Complexity: While many modern robots are designed to be user-friendly, setting up a dual arm robot for a new task can be complex and time-consuming.

- Integration: Integrating dual arm robots into existing workflows can be challenging, particularly in industries that rely on legacy equipment.

Benefits of Dual Arm Robots

The use of dual arm robots offers several key benefits:

- Increased Productivity: With their ability to multitask and work efficiently, dual arm robots can significantly boost productivity in industrial settings.

- Enhanced Precision: Dual arm robots are capable of handling delicate tasks that require a high level of precision, reducing the risk of human error.

- Cost Efficiency: While the initial investment in dual arm robots can be high, the long-term savings in labor costs and increased efficiency often offset the initial expense.

- Safety: Dual arm collaborative robots are designed to work safely alongside humans, reducing the risk of workplace accidents.

The Future of Dual Arm Robotics

As technology continues to evolve, the capabilities of dual arm robots are expected to expand even further. Advances in artificial intelligence, machine learning, and sensor technology will likely make these robots even more versatile, adaptable, and capable of handling complex tasks in a wide range of industries.

In particular, the development of more sophisticated dual arm collaborative robots will likely lead to greater integration of robotics into workplaces where humans and robots work side by side to achieve common goals.

Conclusion

Dual arm robots are revolutionizing the way industries approach automation, offering unmatched flexibility, precision, and efficiency. From manufacturing and assembly to healthcare and packaging, these robots are quickly becoming indispensable in various industries. As technology continues to advance, the potential for dual arm robots to reshape industrial automation is limitless.

If you’re looking to stay ahead in the world of industrial automation, now is the time to consider how dual arm robots can benefit your business.

Explore more about dual arm robots and other automation technologies at EngiTech. Stay updated with the latest innovations in industrial drying and automation technologies!