Master the Paddle Dryer Working Principle with This Guide

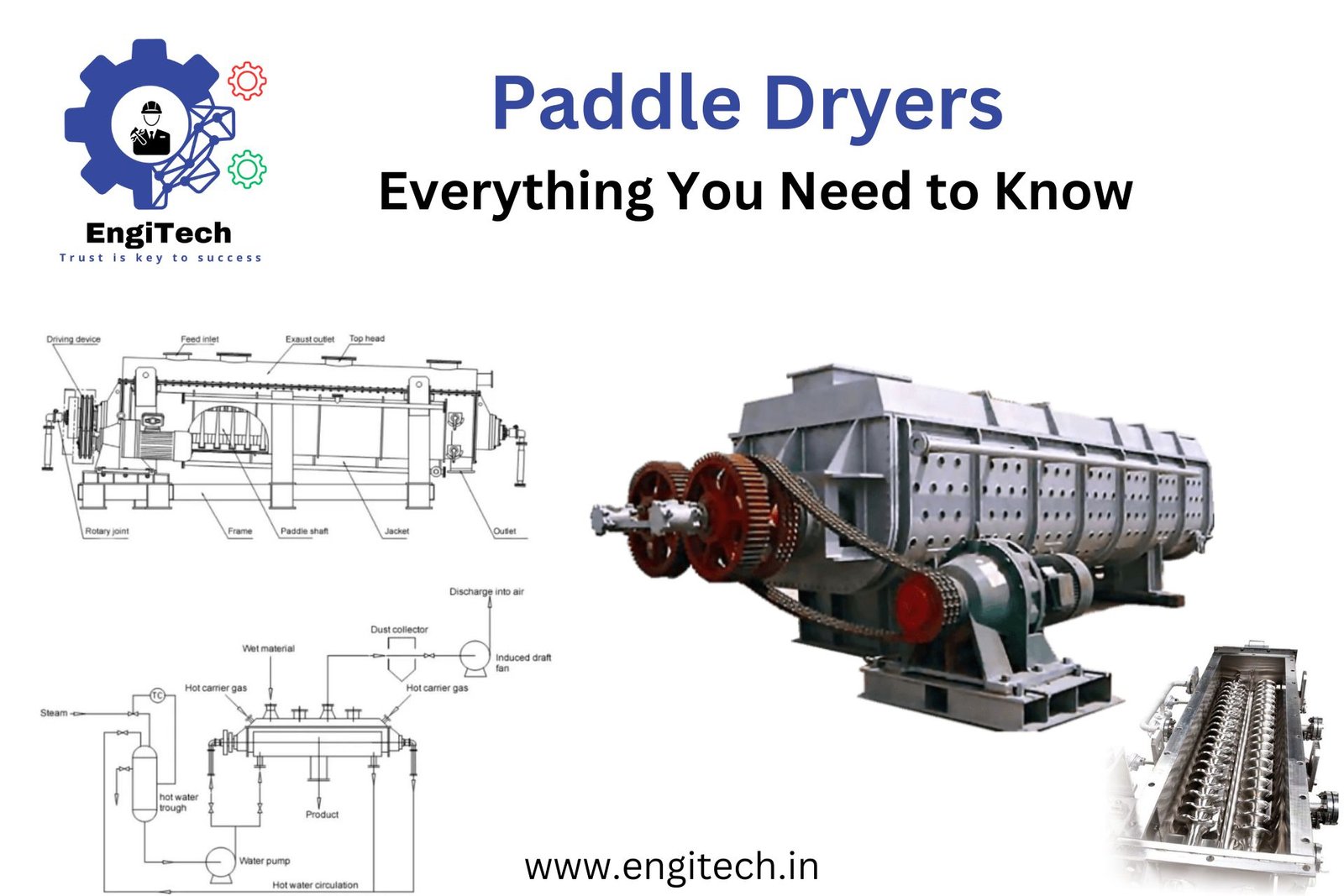

In various industrial processes, especially within the chemical, pharmaceutical, and food sectors, paddle dryers have become essential tools. Their versatility and high efficiency make them invaluable for handling a wide range of materials. This blog aims to delve into the paddle dryer working principle, exploring how they operate and the variations in configurations that can impact their performance, particularly when utilizing steam and thermic fluid plant options.

Table of Contents

What is a Paddle Dryer?

A paddle dryer is a highly efficient piece of equipment used to dry materials by indirect heat transfer drying heating. It consists of a horizontal, cylindrical vessel equipped with rotating paddles that ensure thorough mixing and heat transfer. This design is particularly advantageous for drying materials with high moisture content or those that are sticky and pasty.

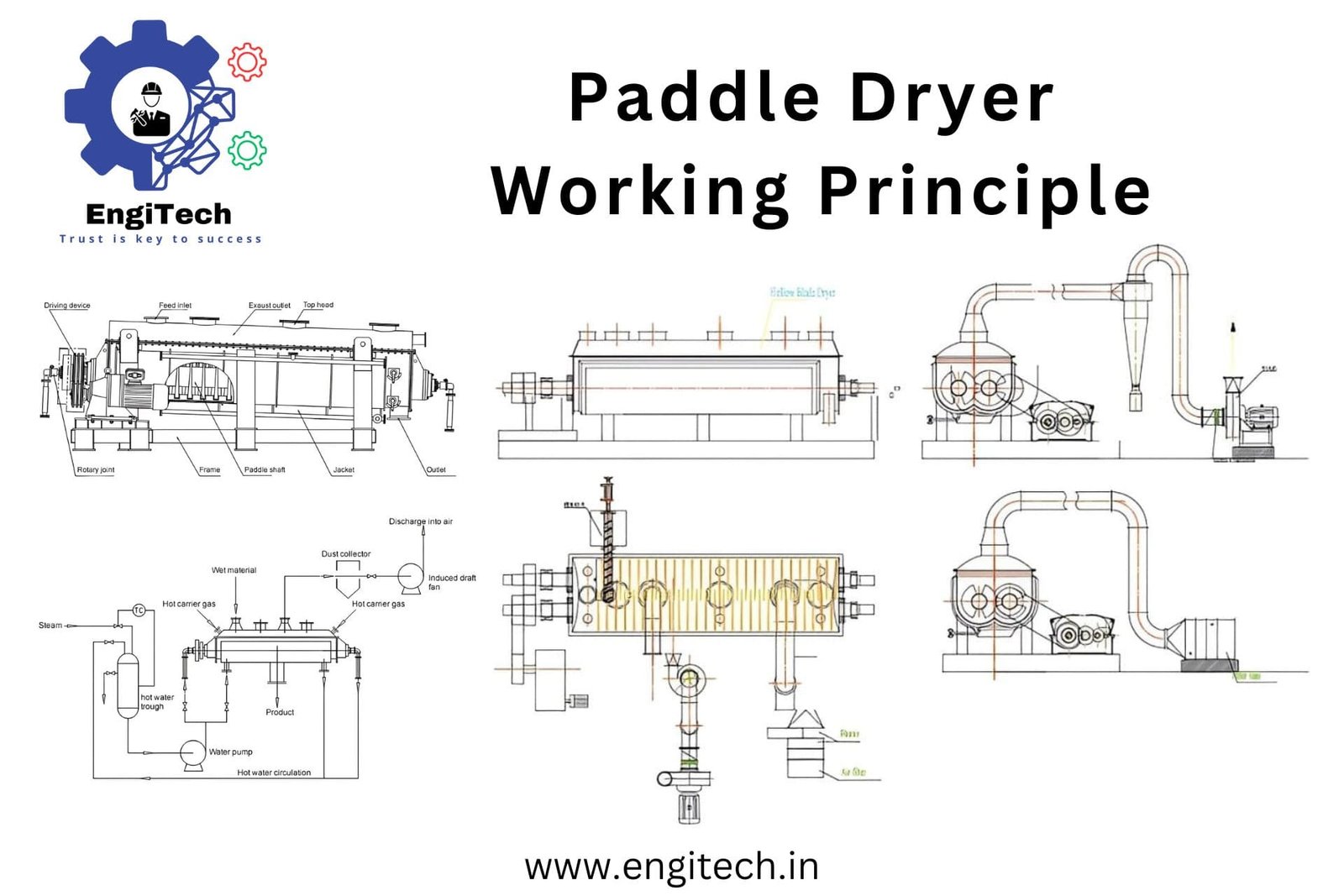

Paddle Dryer Working Principle

At the core of the paddle dryer is its working principle, which revolves around indirect heating. Here’s a step-by-step look at how a paddle dryer operates:

1. Feed Material Introduction:

- The paddle dryer receives the material to be dried through an inlet.

- Ensuring a consistent flow of material is crucial for efficient drying.

2. Indirect Heating in Paddle Dryers:

- Paddle dryers utilize indirect heating, meaning the heating medium (steam or thermic fluid) does not come into direct contact with the material.

- The heating medium flows through the jacket and hollow paddles, transferring heat to the material.

3. Heat Transfer in Paddle Dryers:

- As the paddles rotate, they mix the material, ensuring uniform heat distribution.

- The dryer walls and paddles conduct heat from the heating medium, evaporating the moisture.

4. Vapor Removal in Paddle Dryers:

- The system collects and removes the evaporated moisture via a vapor outlet.

- Some systems include a vacuum to enhance evaporation, particularly for heat-sensitive materials.

5. Material Discharge in Paddle Dryers:

- The system continuously discharges the dried material, maintaining a steady production flow.

Variations in Paddle Dryer Working Principle: Steam vs. Thermic Fluid

The operation of paddle dryers can vary significantly depending on whether they use steam or thermic fluid as the heating medium. Each configuration offers distinct advantages and considerations.

Steam-Heating Paddle Dryer

Steam-Heating Paddle Dryer Working Principle:

- Steam serves as the heating medium.

- It flows through the jacket and hollow paddles, condensing upon contact with cooler surfaces and releasing latent heat.

- This heat is then conducted through the dryer walls and paddles, drying the material efficiently.

Key Considerations for Steam-Heating Paddle Dryers:

- Temperature Control: Steam temperature can be precisely controlled, ensuring consistent drying conditions.

- Heat Transfer Efficiency: Steam offers high heat transfer efficiency, enabling rapid and uniform drying.

- Pressure Management: Proper management of steam pressure is essential for optimal performance and safety.

Thermic Fluid-Heating Paddle Dryer

Thermic Fluid-Heating Paddle Dryer Working Principle:

- A thermic fluid, such as thermal oil, serves as the heating medium.

- The fluid flows through the jacket and hollow paddles, transferring heat to the material.

- This heat evaporates the moisture from the material.

Key Considerations for Thermic Fluid-Heating Paddle Dryers:

- Temperature Range: Thermic fluids play a crucial role in operating at higher temperatures than steam, making them suitable for materials requiring higher drying temperatures.

- Heat Transfer Control: Precise control of heat transfer rates accommodates various drying requirements., including those achieved with vacuum paddle dryers.

- Maintenance: Regular maintenance is required to ensure the thermic fluid remains effective and to prevent degradation.

Advantages of Paddle Dryers

Paddle dryers offer several notable advantages that make them a preferred choice across industries:

- Versatility :They can handle a broad range of materials, including slurries, pastes, and granular solids.

- Efficiency :Indirect heating ensures efficient heat transfer, reducing energy consumption and operational costs while using less energy for optimal drying performance.

- Uniform Drying :Rotating paddles ensure thorough mixing and uniform heat distribution.

- Scalability :Available in various sizes and capacities, making them suitable for different scales of operation.

- Controlled Environment :The closed system minimizes contamination risk and allows precise control over drying conditions.

Components of a Paddle Dryer

A paddle dryer consists of several integral components that facilitate its effective operation. The vessel, typically insulated, allows for indirect heating, ensuring uniform heat distribution and minimizing heat loss. Hollow paddles mounted on a shaft enhance heat transfer, enabling efficient drying of various materials. Additionally, a temperature control system ensures optimal performance by maintaining desired moisture content. Auxiliary elements, such as a scraper mechanism, prevent material buildup on the dryer walls, while providing continuous operation, crucial for maintaining low operational costs and high efficiency.

Product Models or Variants of Paddle Dryers

Paddle dryers come in various models and variants, each tailored to meet specific industrial needs and applications. Among the most recognized product models are the standard paddle dryer, vacuum paddle dryer, and continuous paddle dryer. The standard paddle dryer is ideal for general drying applications across multiple sectors, thanks to its efficient heat transfer and versatile design.

On the other hand, the vacuum paddle dryer is designed specifically for heat-sensitive materials, allowing for drying under reduced pressure, which minimizes evaporation heat loss. Lastly, continuous paddle dryers are engineered for high-capacity operations, featuring a continuous feed and discharge system that maximizes productivity. Each of these models offers unique features and specifications catering to diverse material types and drying requirements, ensuring that industries can select the most suitable paddle dryer variant for their specific processes.

Unique Selling Points or Differentiators of Specific Paddle Dryers

When it comes to selecting paddle dryers for industrial applications, understanding the unique selling points (USPs) or differentiators of specific models becomes crucial in making an informed decision. Each variant of paddle dryer, whether it be the standard, vacuum, or continuous model, presents distinct features tailored to meet particular operational needs. For instance, vacuum paddle dryers stand out for their ability to dry heat-sensitive materials without risking thermal degradation, making them ideal for the pharmaceutical and food industries. Similarly, continuous paddle dryers offer the advantage of uninterrupted operation, allowing for high-volume production while maintaining consistent product quality.

Furthermore, advanced features such as integrated controls for precise temperature management and optimized heat recovery systems differentiate them from conventional dryers, leading to enhanced energy efficiency and reduced operational costs. Overall, these unique selling points not only enhance the performance and reliability of paddle dryers but also provide businesses with compelling reasons to select a model that aligns with their specific process requirements.

Key Elements and Functions of Paddle Dryer Components

Introducing the feed material into paddle dryers sets the stage for an efficient drying process. Materials are typically conveyed through a series of hollow paddles that facilitate indirect heating, ensuring uniform heat distribution while minimizing heat loss. As the feed material moves, its moisture content gradually decreases thanks to precise control of temperature and heating medium. This method, including the use of a scrubber tank, is especially effective for sensitive materials, making paddle dryers a preferred choice across various industries, particularly food processing and chemical applications.

Design Considerations for Paddle Dryers

Various elements play a crucial role in the design of paddle dryers to ensure optimal performance. Factors such as heat transfer efficiency, uniform heat distribution, and the selected heating medium—either thermal oil or hot water—are pivotal to achieving efficient drying through advanced heat recovery systems. Additionally, considerations for operational costs, energy consumption, and the specific material type, whether sensitive or sticky, must be taken into account. These elements collectively contribute to a paddle dryer’s energy efficiency and drying capabilities while meeting industrial demands.

Applications of Paddle Dryers

Paddle dryers are employed in various industries due to their versatility and efficiency:

- Chemical Industry:Drying chemicals, intermediates, and catalysts.

- Pharmaceutical Industry:Drying active pharmaceutical ingredients (APIs) and excipients.

- Food Industry:Drying food products, additives, and ingredients.

- Environmental Engineering:Treating and drying sludge and waste materials.

Conclusion

Understanding the paddle dryer working principle is vital for industries looking to improve their drying processes and enhance their drying efficiency. Whether utilizing steam or thermic fluid, paddle dryers provide versatility, efficiency, and uniform drying. By selecting the appropriate configuration and maintaining optimal operating conditions, industries can achieve consistent and high-quality drying outcomes.

Paddle dryers are essential in chemical, pharmaceutical, food, and environmental sectors, enhancing productivity and product quality. As technology advances, paddle dryers will continue to evolve, offering an efficient solution for even greater efficiency and capabilities.

For more detailed information on paddle dryers and other industrial drying equipment, visit EngiTech. Stay updated with our latest blogs to enhance your knowledge and improve your industrial processes.

We recommended AS Engineers, we are working with them from many year and we highly recommend them for paddle dryer, they are the best paddle dryer manufacturer in India