Paddle Dryer for Sludge: A Comprehensive Guide

Efficient handling of sludge is a crucial step in both wastewater treatment and industrial processes. Through better drying of the sludge, you are practically reducing the bulk and weight of it, thus making all the processes around it easier to manage, move, and get rid of it. Paddle dryers by the way are some of the most efficient machines in this regard. The blog below will outline the specific benefits of the paddle dryers for this element, it shall also describe the working of the paddle dryers.

Table of Contents

What is a Paddle Dryer for Sludge?

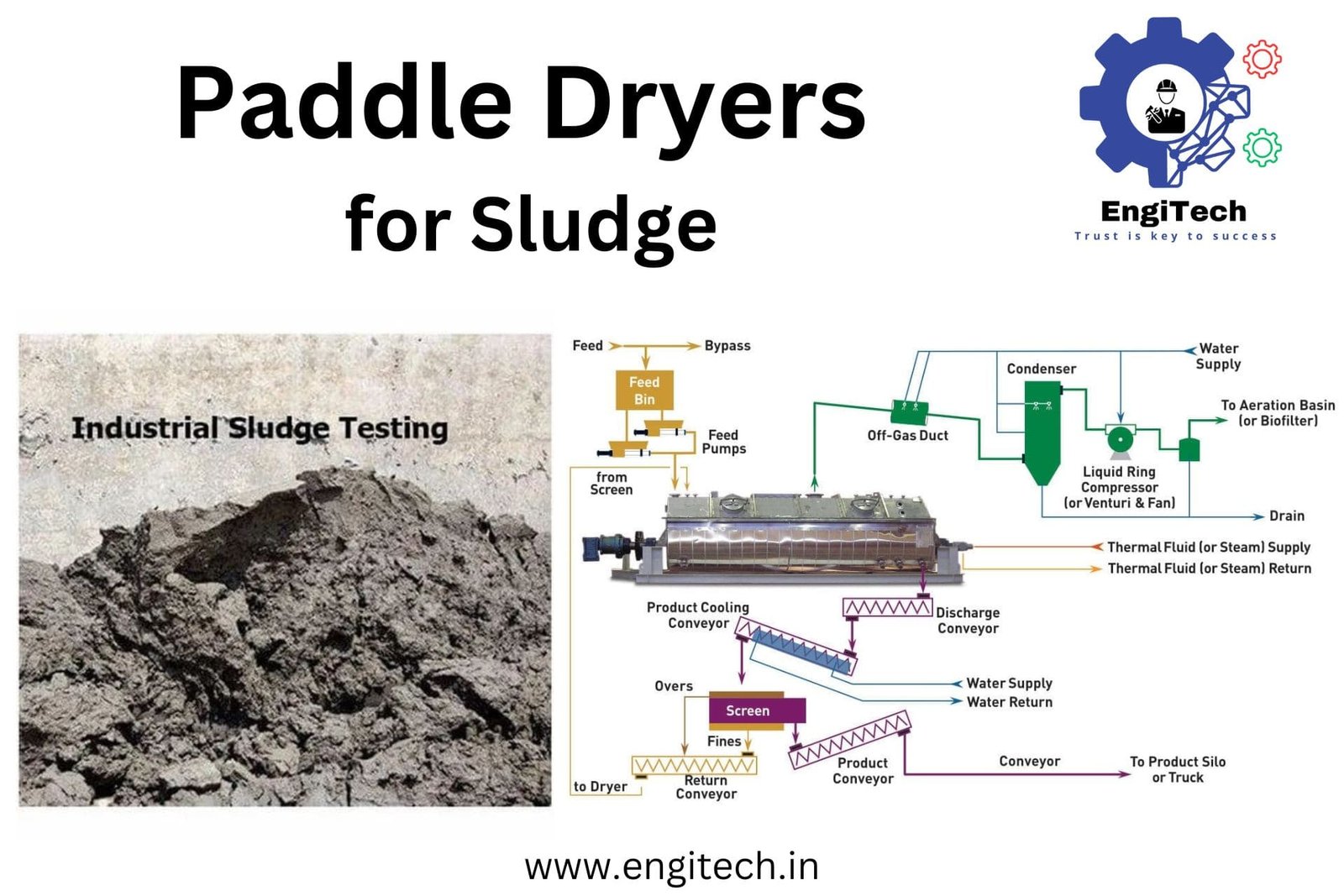

A paddle dryer for sludge is a special device that does this thing efficiently through indirect heating. The equipment consists of a horizontally placed cylindrical vessel in which the sludge is weaved by the rotating paddles. The indirect heating system makes sure that the heating medium is kept away from the sludge. It can be steam/thermic fluid that is heated up to the required temperature and does not touch the sludge. This aids in giving a more controlled and efficient drying process.

Working Principle of Paddle Dryer for Sludge

Working Principle of Paddle Dryer for Sludge

- In the system, the evaporated moisture is captured and drawn away through the vapor outlet.

- Some systems may incorporate a vacuum to facilitate evaporation and in addition to that a condenser for the separation of vapor generated in the dryer may also be included.

5. Dried Sludge Discharge:

- The system operates continuously shedding dried sludge thus ensuring a constant production flow.

Benefits of Using Paddle Dryers for Sludge

1. Efficient Drying Process:

- Paddle dryers are highly efficient heat transfer units due to their ability to provide mixing, which ensures a uniform drying process.

- The sludge indirect heating method provides the dried product with no contact with the heater, thus avoiding cross-contamination.

2. Reduced Sludge Volume:

- Sludge drying in a paddle dryer leads to an extreme reduction in its volume and weight.

- This method together with the reduced sludge volume, makes its handling, transportation, and disposal easy and inexpensive.

3. Energy Efficiency:

- Scuts mainly reduce the energy usage and consequently the total costs by the optimum energy design.

- The mixing process is semi-empirical and very efficient which allows to transfer of more heat and thus requires less energy.

4. Vapor Removal:

- In the system, the evaporated moisture is captured and drawn away through the vapor outlet.

- Some systems may incorporate a vacuum to facilitate evaporation and in addition to that a condenser for the separation of vapor generated in the dryer may also be included.

5. Dried Sludge Discharge:

- The system operates continuously shedding dried sludge thus ensuring a constant production flow.

Benefits of Using Paddle Dryers for Sludge

1. Efficient Drying Process:

- Paddle dryers are highly efficient heat transfer units due to their ability to provide mixing, which ensures a uniform drying process.

- The sludge indirect heating method provides the dried product with no contact with the heater, thus avoiding cross-contamination.

2. Reduced Sludge Volume:

- Sludge drying in a paddle dryer leads to an extreme reduction in its volume and weight.

- This method together with the reduced sludge volume, makes its handling, transportation, and disposal easy and inexpensive.

3. Energy Efficiency:

- Scuts mainly reduce the energy usage and consequently the total costs by the optimum energy design.

- The mixing process is semi-empirical and very efficient which allows to transfer of more heat and thus requires less energy.

4. Versatility:

- Paddle dryers can handle various types of sludge, including municipal, industrial, and biological sludge.

- Their robust design and adaptability make them suitable for different sludge drying applications.

5. Environmental Compliance:

- Efficient sludge drying helps meet environmental regulations by reducing the volume of waste that needs to be disposed of.

- You can safely landfill properly dried sludge or use it in other applications, such as soil conditioning or energy recovery.

Best sludge management solution

Applications of Paddle Dryers in Sludge Management

Paddle dryers are widely used in various industries for effective sludge management:

1. Municipal Wastewater Treatment:

- Municipal wastewater treatment plants commonly use paddle dryers to dry sewage sludge.

- You can safely dispose of or utilize the dried sludge in agricultural applications.

2. Industrial Waste Treatment:

- Industries producing large volumes of sludge, such as chemical, pharmaceutical, and food processing industries, use paddle dryers for sludge management.

- Efficient sludge drying helps reduce waste disposal costs and meet environmental regulations.

3. Biological Sludge Management:

- Paddle dryers effectively dry biological sludge generated from various biological treatment processes.

- You can use the dried biological sludge for energy recovery or as a soil conditioner.

Choosing the Right Paddle Dryer for Sludge

When selecting a paddle dryer for sludge, consider several factors to ensure optimal performance and efficiency:

1. Capacity and Throughput:

- Determine the volume of sludge you need to process to choose a paddle dryer with the appropriate capacity and throughput.

2. Heating Medium:

- Decide whether to use steam, thermic fluid, or hot water as the heating medium based on your specific drying requirements and available resources.

3. Material Compatibility:

- Ensure that the materials used in constructing the paddle dryer are compatible with the type of sludge being processed to prevent corrosion and wear.

4. Automation and Control:

- Consider paddle dryers with advanced automation and control features for precise temperature and process control, ensuring consistent drying quality.

5. Energy Efficiency:

- Look for paddle dryers designed to optimize energy usage and reduce operational costs.

Conclusion

Paddle dryers offer an efficient and effective solution for sludge management in various industries. By providing uniform drying through indirect heating, they significantly reduce sludge volume and weight, making handling and disposal more manageable. The versatility, energy efficiency, and environmental compliance of paddle dryers make them invaluable tools for municipal wastewater treatment, industrial waste treatment, and biological sludge management.

Understanding the working principle and benefits of paddle dryers for sludge is crucial for industries seeking to improve their sludge management processes. By choosing the right paddle dryer and maintaining optimal operating conditions, you can achieve consistent, high-quality drying outcomes, contributing to a more sustainable and cost-effective waste management strategy.

For more detailed information on paddle dryers and other industrial drying equipment, visit EngiTech. Stay updated with our latest blogs to enhance your knowledge and improve your industrial processes.