Packing Machine Small: The Definitive Guide to Compact Packaging Solutions

Have you ever looked at your packaging process and thought, “There must be a more efficient way to handle this”? If so, you’re not alone. In today’s competitive market, businesses are constantly seeking new methods to streamline packaging—without sacrificing quality or profitability. This is where the concept of a packing machine small comes into play. In this comprehensive guide, we’ll explore why small packing machines are rapidly gaining traction, how to pick the right one for your unique needs, and the real-world benefits you can expect after implementation.

Packaging is a critical element of any product-focused business—whether you’re shipping gourmet cookies to loyal fans or delicate electronics to tech-savvy customers. At first glance, it may seem like a minor step in the overall production line. Yet, the truth is that efficient packaging can bolster brand reputation, enhance the customer experience, and significantly reduce operational costs. By the end of this article, you’ll understand everything you need to know about small packing machines—how they work, how to maintain them, and how to seamlessly integrate them into your workflow.

Table of Contents

Understanding the Rising Demand for Small Packing Machines

The modern business landscape is hyper-competitive. From tiny, home-based startups to massive manufacturing plants, everyone is seeking an edge to save time, reduce waste, and maintain quality. As consumer expectations skyrocket—especially with the surge in e-commerce—packaging is no longer a trivial step. It’s a crucial element of brand identity and operational efficiency.

- Growing E-Commerce Market: Online retailers ship thousands of packages daily. In such a climate, a delay of even a few hours can lead to dissatisfied customers and negative reviews. Small packing machines empower businesses to automate repetitive tasks, speeding up the packaging process without requiring large amounts of floor space.

- Rising Labor Costs: Manual labor can be expensive. Training, salaries, and the risk of human error all contribute to overhead. Compact packaging machines significantly cut labor needs while ensuring consistency, allowing teams to focus on activities that add higher value—like marketing, product development, or customer service.

- Lean Manufacturing Principles: “Lean” is more than just a buzzword; it’s a set of principles that aim to eliminate waste. Small packing machines fit perfectly into lean frameworks. They’re typically more economical and require less maintenance than their larger counterparts, yet can automate and streamline critical packaging operations.

For instance, consider a small bakery that ships homemade pastries. Before implementing a small packaging solution, the bakery might rely on manual sealing, labeling, and boxing. Each box could take a minute or more to pack. Multiply that by hundreds of orders, and you have a bottleneck that can quickly become unmanageable. A compact packing machine—whether it’s for sealing, labeling, or vacuum packing—can reduce that minute to mere seconds.

Why “Packing Machine Small” Is the Future of Efficient Packaging

It’s no coincidence that when you search for solutions to improve packaging, one of the top queries is “packing machine small.” Businesses want smaller footprints, greener solutions, and more cost-effective methods to handle packaging demands. Here’s why small packing machines continue to dominate:

- Space Efficiency: A smaller machine means you can place it in cramped areas or easily move it if you need to reconfigure your layout. This flexibility is especially valuable for businesses expanding or adapting to seasonal demands.

- Cost-Effectiveness: Larger machines often come with hefty price tags, not to mention higher ongoing maintenance costs. In contrast, small packing machines deliver many of the same benefits without the financial strain.

- Scalability: Today’s small packing machines often feature modular designs, allowing you to add attachments or upgrade components as your business grows.

- Energy Conservation: With sustainability becoming an increasingly important factor for both businesses and consumers, energy-efficient small packing machines are a more eco-friendly solution.

- Ease of Use: Modern small packing machines come with user-friendly interfaces, intuitive settings, and quick-start guides. This simplicity lowers the learning curve for employees and reduces training time.

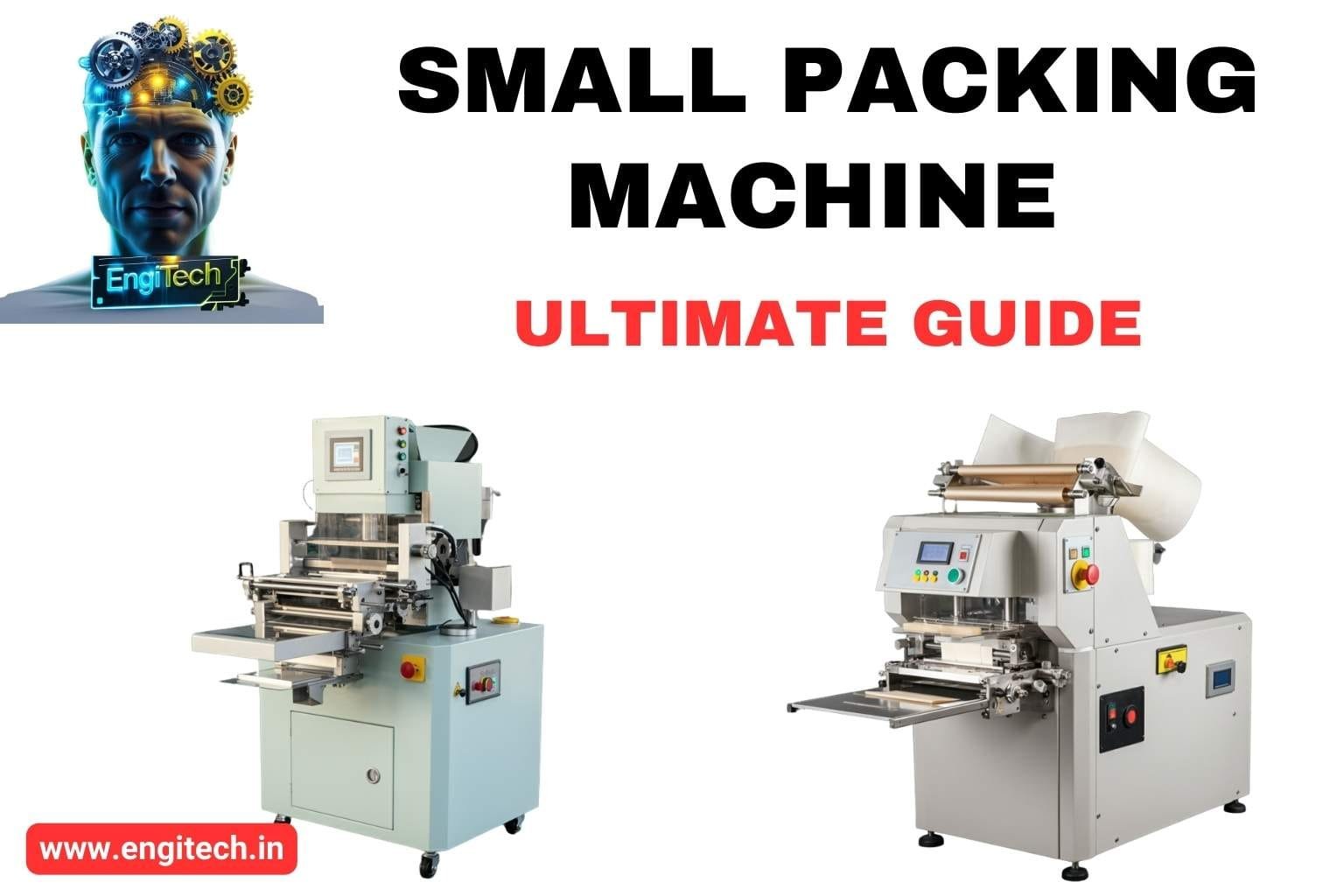

Common Types of Small Packing Machines

When people discuss “small packing machines,” they’re often referring to a variety of specialized tools designed to fit different industry needs. Let’s break down the most common types you might encounter.

3.1 Food Packaging Solutions

Food packaging demands strict adherence to hygiene and safety standards. Within this category, you’ll find:

- Vacuum Sealers: Ideal for perishable goods like cheese, meats, and prepared meals. Vacuum sealing extends shelf life by removing air that can harbor bacteria.

- Thermoformers: Although not always labeled “small,” many compact thermoforming machines are tailored for small to medium-sized businesses that need sealed trays or blister packaging.

- Flow Wrappers: Perfect for packaging bread, pastries, and other baked goods in individual wrappers for freshness.

These machines often come equipped with stainless steel bodies and easy-to-clean surfaces to comply with sanitation guidelines set by agencies like the U.S. Food & Drug Administration.

3.2 Industrial Packaging Solutions

If your business revolves around parts, hardware, or even small electronic components, you might be looking at:

- Shrink Wrapping Machines: Efficient for bundling products together—such as sets of screws or electronic accessories—while protecting them from dust and moisture.

- Case Sealers and Carton Erectors: Save time on assembling boxes and sealing them. Compact versions can be fitted onto most production lines, even in tight spaces.

- Pouch Fillers: For industries that require pouches—like powdered supplements or small hardware kits—these mini filling systems can weigh, fill, and seal in one streamlined process.

3.3 E-Commerce Packaging Solutions

With online sales skyrocketing, specialized e-commerce packing solutions have emerged to address shipping challenges:

- Automated Poly Baggers: These machines place smaller items—like clothing or gadgets—into poly mailers and seal them instantly.

- Label Printers & Applicators: Eliminate the manual step of printing labels and sticking them on each package. Compact labeling machines can drastically speed up your dispatch process.

- Protective Packaging Systems: Machines that create inflatable cushions or padding on demand, ensuring that delicate products arrive safely without taking up extensive storage for bulky packaging materials.

Key Features to Look for When Buying a Compact Packing Machine

So, you’ve decided that small packing machines could be a game-changer for your business. But what should you really be looking out for? Here are some critical features to consider:

- Machine Footprint and Mobility

- Check the machine’s dimensions and required clearance.

- Look for caster wheels or handles if you anticipate rearranging your production area frequently.

- Speed and Throughput

- Measure how many units per hour the machine can handle.

- Consider whether that rate aligns with your peak production requirements.

- Keep in mind that some machines list theoretical maxima that may differ from real-world numbers.

- Versatility and Adjustability

- Can the machine handle multiple product sizes?

- Does it support different packaging materials (e.g., poly bags, shrink film, cartons)?

- If you sell seasonal or varied products, an adaptable machine can offer significant long-term value.

- Ease of Maintenance

- Look for machines with removable parts for easy cleaning.

- Check for available service centers or online tutorials.

- User-friendly designs with minimal points of failure can save you hours of downtime.

- Safety Features

- Ensure compliance with local regulations (e.g., Occupational Safety and Health Administration guidelines in the U.S.).

- Look for emergency stop buttons, protective covers, and clear safety instructions.

- Automation Level

- Some small packing machines are semi-automatic, requiring an operator to initiate certain actions. Others are fully automated, drastically minimizing labor.

- Decide which level suits your workforce and budget.

- Cost vs. ROI

- Balance upfront costs with expected ROI—consider reduced labor expenses, fewer errors, and enhanced throughput.

- A cheaper machine that breaks down frequently or can’t keep up with demand might cost more in the long run.

Step-by-Step Guide: Choosing the Right Packing Machine Small for Your Business

Deciding on a small packing machine can be daunting, particularly when you’re flooded with technical jargon. Here’s a straightforward, step-by-step approach to guide your decision:

- Define Your Packaging Needs

- List the products you aim to package.

- Identify what packaging form you prefer (boxes, pouches, shrink wrap, flow wrap, etc.).

- Assess Your Production Volume

- Calculate average and peak production volumes.

- Look for machines that comfortably handle peak loads, so you won’t outgrow the system too quickly.

- Set a Budget Range

- Determine a realistic budget, considering both machine costs and maintenance fees.

- Remember to factor in potential labor savings and any value-added features that could justify a higher cost.

- Research Machine Types

- Study the main types of small packing machines relevant to your industry.

- Explore brand reputation, read case studies, and watch product demos or video reviews.

- Check for Industry-Specific Requirements

- Food businesses must comply with stricter hygiene standards, so focus on machines with stainless steel frames and easy-to-clean surfaces.

- Electronics might require anti-static packaging options.

- Request Quotes and Samples

- Contact multiple suppliers.

- Ask for quotes, including any extended warranty options.

- If possible, request sample packaging runs to test the quality and speed.

- Compare Service and Support Options

- A machine is only as good as the support you receive when issues arise.

- Investigate parts availability, service response times, and any training sessions offered by the manufacturer.

- Pilot and Review

- Once you’ve narrowed down your options, consider a short-term pilot run.

- Monitor throughput, worker satisfaction, and packaging quality.

- Gather feedback and address any issues before making a final purchase.

Real-World Case Studies and Success Stories

Seeing how other businesses have integrated small packing machines can offer valuable insights. Let’s explore a couple of examples.

- Artisanal Coffee Roaster

- Problem: A family-owned coffee roasting company was packaging beans manually, leading to inconsistent bag weights and slow turnaround times.

- Solution: They invested in a compact pouch filling machine capable of automatically weighing and sealing each bag.

- Outcome: The business sped up its packaging line by 50%, leading to fewer customer complaints about bag weight discrepancies and quicker shipping times.

- Independent Cosmetic Brand

- Problem: A fast-growing cosmetic startup struggled with labeling hundreds of small skincare bottles.

- Solution: They purchased a tabletop labeling machine designed specifically for cylindrical containers.

- Outcome: The brand cut labeling labor in half and maintained a professional, uniform look on every product. They also reduced labeling errors—no more crooked or partially attached stickers.

- Hardware Distributor

- Problem: This distributor shipped boxes of mixed hardware components, which had to be counted and sealed manually.

- Solution: They introduced a small count-and-seal machine, which precisely measured each batch of screws, nuts, and bolts, then sealed them in plastic pouches.

- Outcome: The distributor cut labor costs by 30% and virtually eliminated shipping mistakes caused by miscounts.

Essential Maintenance and Operating Best Practices

To maximize your investment in a packing machine small, regular maintenance and proper operation are critical. Here’s how to keep your machine in prime condition:

- Daily Inspections

- Conduct a quick visual check each morning, ensuring no parts are loose or excessively worn.

- Clear any debris or leftover packaging material from the machine.

- Lubrication Schedule

- Follow the manufacturer’s recommended lubrication points and intervals.

- Using the wrong lubricant or over-lubricating can lead to gear slippage and other mechanical issues.

- Regular Calibration

- If your machine involves weighing, sealing temperatures, or other precise operations, schedule routine calibration checks.

- Maintain a log to track when calibrations occur.

- Cleanliness

- Particularly for food-related operations, thoroughly clean the machine after each production cycle to avoid cross-contamination.

- Use approved cleaning agents and follow any guidelines provided by the manufacturer.

- Operator Training

- Don’t assume all employees understand how to safely operate and maintain the machine.

- Regularly train and retrain staff, especially if the manufacturer provides updates or new features.

- Detailed Record-Keeping

- Record every service, part replacement, or minor fault.

- A log helps diagnose recurring issues and could be invaluable if you ever file a warranty claim.

FAQs: Everything You Need to Know About Small Packing Machines

Below are some frequently asked questions that can help clarify any lingering concerns:

- Q: Is a “packing machine small” powerful enough for high-volume production?

A: Yes, many compact models are engineered for moderate to high output. They offer impressive throughput despite their smaller size, but always verify the machine’s specifications against your peak production needs. - Q: What types of materials can a small packing machine handle?

A: These machines can typically handle an array of packaging materials—such as plastic bags, shrink film, paperboard cartons, or even specialty eco-friendly films. Always confirm compatibility with the vendor to avoid costly mistakes. - Q: Are compact packaging machines suitable for fragile items?

A: Absolutely. Many machines come with adjustable settings for gentle handling. For particularly fragile goods, consider specialized protective packaging systems that use air cushions or custom inserts. - Q: How do I ensure compliance with food safety regulations?

A: Opt for machines specifically designed for food packaging, often featuring stainless steel construction and easy-to-clean surfaces. Always follow guidelines from organizations like the FDA or your local health department. - Q: What is the average return on investment (ROI) for a small packing machine?

A: This varies based on factors like production volume, labor costs, and the specific type of machine. However, many businesses report recouping their investment within a year—sometimes even quicker if they face high packaging labor costs.

Emerging Trends and Innovations in Small Packaging Equipment

Technology is evolving rapidly, and packing machine small designs are no exception. Here are a few innovations transforming how businesses package their products:

- IoT-Enabled Machines

- Internet of Things (IoT) integration allows real-time monitoring of production data.

- Predictive maintenance can alert you before a part fails, minimizing costly downtime.

- Smart Sensors and Automation

- Built-in sensors detect whether a product is positioned correctly.

- This reduces errors and material waste by pausing the machine if items are misaligned.

- Eco-Friendly Packaging Options

- Demand for biodegradable films and recyclable materials is rising.

- Some small packing machines are specifically designed to handle these new, sometimes more delicate, packaging materials.

- Modular, Upgradeable Systems

- Instead of replacing your entire machine as you grow, you can add modular components (e.g., a more advanced sealer, automated label applicator, or integrated weighing system).

- This approach saves capital and adapts with your evolving business needs.

- AR and VR for Maintenance and Training

- Augmented Reality (AR) or Virtual Reality (VR) guides can help new operators learn the machine faster.

- These technologies also offer remote support, allowing technicians to guide your team through repairs in real time.

Conclusion

A packing machine small may look unassuming, but its potential to transform your packaging line is immense. By automating routine tasks, ensuring consistent packaging quality, and freeing up valuable labor hours, these compact machines can dramatically elevate your business operations. From a cost-saving standpoint, many organizations recoup their investment within months, especially if they’re dealing with high shipping volumes or strict packaging requirements.

Still on the fence? Take a moment to evaluate your current packaging workflow. Are you grappling with frequent shipping errors or bottlenecks? Do you find your team spending more time on packaging tasks than on strategic initiatives? A well-chosen small packing machine can be the key to addressing these pain points, unlocking efficiency gains that directly boost your bottom line.

Ready to dive deeper?

- Check out our Comprehensive Packaging Solutions Guide for more tips on optimizing your production line.

- Explore our E-Commerce Shipping Strategies to see how small packing machines can integrate seamlessly with online retail demands.

- Learn about Maintaining Industrial Equipment to extend the life of your machine and reduce downtime.

By investing in a packing machine small, you’re not just purchasing hardware—you’re laying the groundwork for a smoother, more profitable, and customer-centric operation. If you have any lingering questions or want to share your experiences, drop a comment below! We’d love to hear how compact packing machines have revolutionized your business. Feel free to share this post with colleagues or on social media to spread the word about how these machines are reshaping packaging efficiency.

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.