Infrared Dryers: Working Principles, Design, and Applications

Infrared (IR) dryers have become increasingly popular in various industries due to their efficiency and versatility. These dryers use infrared radiation to heat and dry materials, offering numerous advantages over traditional methods. In this blog, you will explore the working principles, design features, cost considerations, and applications of infrared dryers.

Questions This Blog Will Answer:

- What is an infrared dryer?

- How does an infrared dryer work and working principle ?

- What are the design features of infrared dryers?

- What are the primary applications of infrared dryers?

- What does the diagram of an infrared dryer look like?

- What are the cost considerations for infrared dryers?

What is an Infrared Dryer?

An infrared dryer uses infrared radiation to heat and dry materials. Unlike conventional dryers that rely on convection or conduction, IR dryers use electromagnetic radiation to directly heat the material’s surface. This method allows for rapid and uniform drying, making IR dryers ideal for various industrial applications.

How Does an Infrared Dryer Work?

Infrared dryers operate through several key steps, this is the working principle of IR dryer:

- Infrared Radiation Generation: Infrared heaters, typically composed of ceramic, quartz, or halogen elements, generate infrared radiation. These elements emit radiation in the infrared spectrum, which the material’s surface absorbs.

- Heat Transfer: The infrared radiation penetrates the material’s surface and converts into heat. This direct heat transfer method rapidly raises the material’s temperature, causing moisture to evaporate.

- Moisture Evaporation: As the material heats up, moisture evaporates from the surface. This process continues until the material reaches the desired dryness level.

- Air Circulation: Many IR dryers incorporate air circulation systems to remove the evaporated moisture and improve drying efficiency. The combination of infrared heating and airflow ensures uniform drying and prevents overheating.

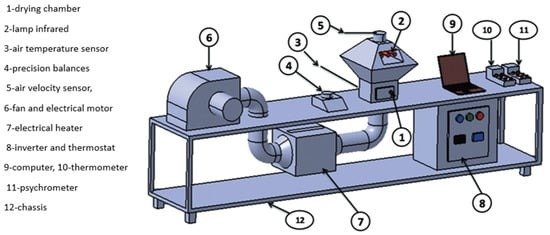

Infrared Dryer Diagram

Below is a simplified diagram of a typical infrared dryer:

- Infrared Heaters: Emit infrared radiation that heats the material.

- Reflectors: Direct the infrared radiation towards the material for even heating.

- Material Conveyor: Transports the material through the dryer.

- Air Circulation System: Removes evaporated moisture and improves drying efficiency.

- Control Panel: Manages the intensity and duration of infrared radiation.

Design Features of Infrared Dryers

Infrared dryers come with various design features that enhance their efficiency and usability:

- Infrared Heaters: Infrared dryers use heaters made from materials like ceramic, quartz, or halogen. These heaters emit uniform and consistent heat, ensuring efficient drying.

- Reflectors: Reflectors around the infrared heaters direct the radiation towards the material, maximizing energy efficiency and ensuring even heating.

- Control Systems: Advanced control systems manage the intensity and duration of infrared radiation. These systems allow precise temperature control, ensuring optimal drying conditions for different materials.

- Air Circulation: Integrated fans or blowers circulate air within the drying chamber, helping to remove moisture and improve drying efficiency.

- Safety Features: Infrared dryers include safety features such as temperature sensors, automatic shut-off systems, and protective screens to prevent overheating and ensure safe operation.

Primary Applications of Infrared Dryers

Infrared dryers find applications across various industries due to their rapid and efficient drying capabilities. Here are some primary uses:

- Textile Industry:

- Drying Fabrics and Garments: IR dryers dry fabrics and garments quickly, reducing processing time and energy consumption.

- Printing and Dyeing: They are used in printing and dyeing processes to set colors and remove moisture from printed textiles.

- Food Industry:

- Drying Food Products: Infrared dryers dry fruits, vegetables, and other food products, preserving their nutritional content and extending shelf life.

- Baking and Cooking: They are used in baking and cooking processes to evenly cook food products and reduce cooking times.

- Paper and Printing Industry:

- Drying Inks and Coatings: IR dryers dry inks and coatings on paper and other substrates, ensuring fast and uniform drying.

- Laminating and Coating: They are used in laminating and coating processes to quickly dry adhesives and coatings.

- Paint and Coating Industry:

- Drying Paints and Coatings: Infrared dryers cure and dry paints and coatings on various surfaces, providing a smooth and durable finish.

- Automotive Industry: They are used in automotive paint booths to speed up the drying process of vehicle paints and coatings.

- Pharmaceutical Industry:

- Drying Powders and Granules: Infrared dryers dry powders and granules, ensuring uniform moisture content and improving product stability.

- Sterilization: They are also used for sterilizing equipment and packaging materials.

Cost Considerations for Infrared Dryers

The cost of infrared dryer varies based on several factors:

- Size and Capacity: Larger and higher-capacity dryers typically cost more due to increased material and construction costs.

- Type of Infrared Heaters: The material and technology used in infrared heaters (ceramic, quartz, halogen) can impact the cost.

- Control Systems: Advanced control systems with precise temperature and airflow management can add to the overall cost.

- Customization: Customization options and additional features such as automated systems and safety mechanisms can increase the cost.

Advantages of Infrared Dryers

- Rapid Drying: Infrared dryers provide fast and efficient drying, significantly reducing processing times compared to conventional methods.

- Energy Efficiency: By directly heating the material’s surface, IR dryers minimize energy loss and improve overall energy efficiency.

- Uniform Heating: Infrared radiation ensures even heating of the material, preventing hotspots and ensuring uniform drying.

- Versatility: IR dryers can handle a wide range of materials, making them suitable for various industrial applications.

- Compact Design: Infrared dryers have a compact design, making them easy to integrate into existing production lines.

Disadvantages of Infrared Dryers

- Initial Cost: The initial investment for infrared dryers can be higher compared to traditional drying methods.

- Material Suitability: Not all materials are suitable for infrared drying, and some may require specific adjustments to the drying process.

- Maintenance: Regular maintenance is required to ensure optimal performance and prevent downtime.

Conclusion

Infrared dryer are essential in industries requiring rapid and efficient drying processes. Their ability to provide uniform heating, energy efficiency, and versatility makes them a preferred choice for many applications. By understanding their working principles and applications, businesses can optimize their drying processes and improve product quality.

For more in-depth articles and resources on industrial drying technologies and innovations, visit EngiTech.in. Stay updated on the latest advancements and applications in the industry!