Agitated pan dryers are essential tools in various industries, particularly where precision drying of solid and semi-solid materials is crucial. This article will provide a detailed overview of agitated pan dryers, their working principles, design features, and applications.

Key Questions Answered:

- What is an agitated pan dryer?

- How does an agitated pan dryer work?

- What are the design features of agitated pan dryers?

- What are the primary applications of agitated pan dryers?

What is an Agitated Pan Dryer?

An agitated pan dryer is an industrial device used for drying solid and semi-solid materials. It features an agitator that continuously stirs the material, ensuring even heat distribution and preventing clumping. These dryers are widely used in industries such as pharmaceuticals, chemicals, and food processing due to their efficiency and ability to handle sensitive materials.

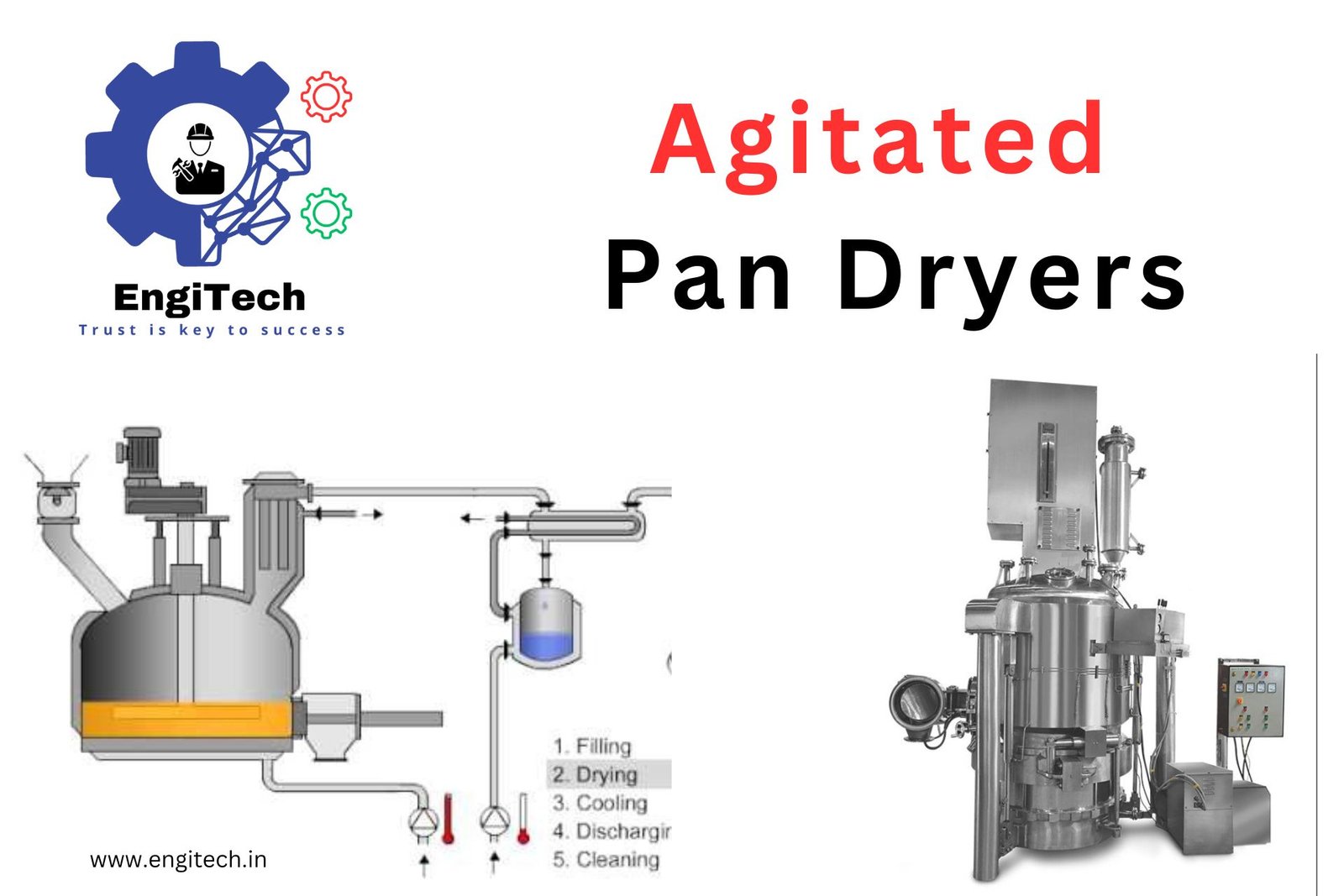

How Does an Agitated Pan Dryer Work?

The working principle of an agitated pan dryer involves several key steps:

- Material Loading:

- Materials are loaded into the pan dryer manually or through automated systems.

- Heating:

- The dryer uses either direct or indirect heating methods. Direct heating involves passing hot air over the material, while indirect heating heats the pan using steam, oil, or electric heaters.

- Agitation:

- The agitator continuously stirs the material, ensuring uniform heat distribution and preventing clumping.

- Drying Process:

- As the material heats, moisture evaporates and is carried away by an airflow system, ensuring consistent and controlled drying.

- Material Discharge:

- Once the desired moisture content is achieved, the dried material is discharged for further processing or packaging.

Design Features of Agitated Pan Dryers

Agitated pan dryers come with various design features that enhance their efficiency and usability:

- Construction Material:

- Typically made from stainless steel or other corrosion-resistant materials.

- Insulated inner surfaces minimize energy loss and enhance efficiency.

- Heating Systems:

- Utilize hot air, steam, oil, or electric heaters.

- Equipped with high-quality heat exchangers for consistent heating.

- Air Circulation:

- Efficient air circulation systems improve airflow and decrease drying time.

- Air patterns can be counterflow, parallel flow, or combined flow.

- Agitation Mechanism:

- The agitator can be configured as a paddle, ribbon, or blade, depending on the material.

- Ensures even heat distribution and prevents clumping.

- Control Systems:

- Advanced control mechanisms manage temperature and airflow accurately.

- Available in automated or semi-automated configurations.

Primary Applications of Agitated Pan Dryers

Agitated pan dryers are versatile and find applications in various industries due to their ability to handle different materials and drying requirements. Here are some primary uses:

- Pharmaceutical Industry:

- Drying Active Pharmaceutical Ingredients (APIs): Ensures APIs achieve the desired moisture content without degradation.

- Drying Granules and Powders: Provides uniform drying essential for consistent tablet production.

- Chemical Industry:

- Drying Fine Chemicals and Intermediates: Offers precise control over drying conditions, essential for chemical processes.

- Handling Temperature-Sensitive Materials: Ideal for drying temperature-sensitive chemicals, maintaining their stability and integrity.

- Food Industry:

- Drying Food Ingredients: Used for drying spices, herbs, and other food additives, ensuring they retain their quality and flavor.

- Preserving Nutrients: Helps preserve the nutritional content of food products through controlled drying environments.

- Cosmetics Industry:

- Drying Powders and Pastes: Ensures uniform consistency and quality in cosmetic products.

- Preserving Active Ingredients: Maintains the efficacy of active ingredients in cosmetics through precise drying control.

Advantages of Agitated Pan Dryers

- Uniform Drying:

- Ensures even drying of materials, leading to high-quality results.

- Versatility:

- Can handle a wide range of materials, making them suitable for various industrial applications.

- Controlled Environment:

- Allows for precise control over drying conditions, ensuring the integrity and quality of the dried material.

- Efficiency:

- Offers enhanced drying efficiency and faster drying times, reducing energy consumption and operational costs.

- Heat Sensitivity:

- Ideal for drying heat-sensitive materials due to the ability to dry at lower temperatures with precise control.

Disadvantages of Agitated Pan Dryers

- Initial Cost:

- The initial investment for agitated pan dryers can be high compared to other drying methods.

- Maintenance:

- Requires regular maintenance to ensure optimal performance and prevent downtime.

- Complexity:

- Advanced control systems and agitation mechanisms add to the complexity of operation and maintenance.

Conclusion

Agitated pan dryers are essential in industries requiring precise and controlled drying processes. Their ability to handle sensitive materials, provide uniform drying, and operate efficiently makes them a preferred choice for many applications. By understanding their working principles and applications, businesses can optimize their drying processes and improve product quality.

For more in-depth articles and resources on industrial drying technologies and innovations, visit EngiTech.in. Stay updated on the latest advancements and applications in the industry!