Hand Seal Machine: The Ultimate Guide to Efficient Packaging Solutions

Have you ever been frustrated by torn plastic bags, leaky pouches, or poorly sealed packages that compromise product quality? If so, you’re not alone. Packaging plays a critical role in preserving goods—be it in a bustling warehouse or your own kitchen. This is precisely where a hand seal machine can be a game-changer. By creating airtight seals in mere seconds, these portable devices cater to small businesses, home-based entrepreneurs, and even everyday consumers.

In this comprehensive guide, you’ll learn everything you need to know about hand seal machines—from their various types and core functionalities to expert maintenance tips and buying advice. By the end, you’ll have a clear roadmap for choosing the right hand seal machine to streamline your packaging process, save money, and maintain professional-grade quality.

Table of Contents

1. Understanding Hand Seal Machines

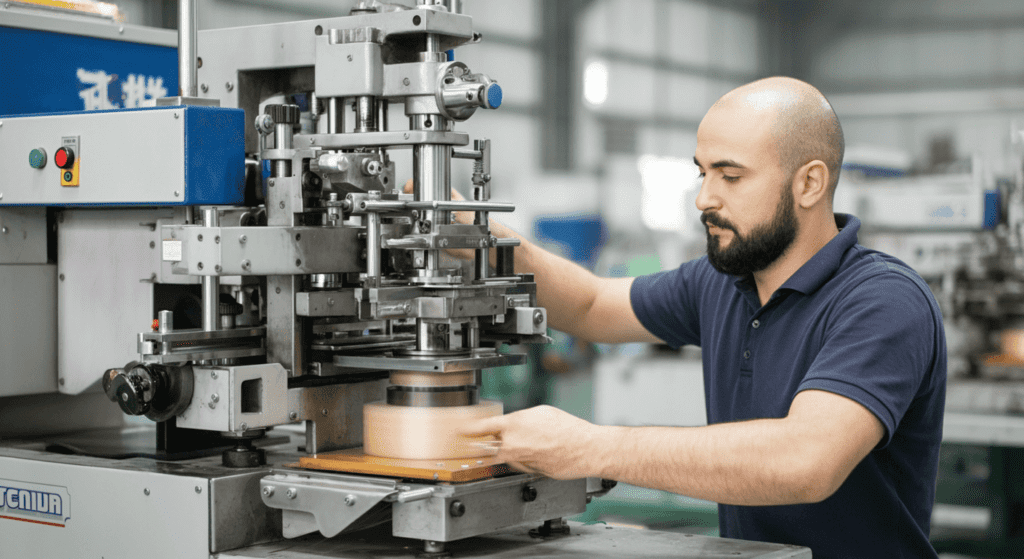

A hand seal machine is a simple yet powerful packaging tool designed to create airtight and watertight seals on bags or pouches. Generally operated by manually pressing down a sealing arm, it’s perfect for poly bags, Mylar bags, cellophane wrappers, and a variety of flexible plastic materials. The ability to create a secure seal not only protects product integrity but also extends shelf life—particularly important in food-related applications and industries where contamination or spoilage must be minimized.

Why the Buzz Around Hand Sealers?

Hand sealers are beloved for their portability and user-friendly nature. Whether you’re a craftsperson selling handmade soaps online, a home-based bakery packaging cookies, or a large enterprise looking to minimize product waste, a hand seal machine offers a level of convenience that’s hard to beat. By precisely controlling heat and pressure, these machines form seals that can match—if not exceed—factory standards.

2. How Hand Sealers Work: The Science of Heat and Pressure

At their core, hand seal machines utilize a combination of heat, pressure, and time. When the sealing arm is lowered and pressure is applied to the bag, a thin wire or strip (depending on the machine’s design) transmits the heat necessary to melt and fuse the layers of plastic together.

- Heat Generation: An electrical circuit powers a heating element in the sealing bar or wire.

- Application of Pressure: The operator presses the handle down against the sealing surface, compressing the layers of plastic.

- Cooling Period: Once the plastic fuses, the machine briefly cools the seal to lock it in place.

The exact temperature and duration can vary. Impulse sealers heat up for just a short pulse, while constant heat sealers maintain a steady temperature. Regardless, the principle remains the same: heat + pressure = a secure, reliable seal.

3. Types of Hand Seal Machines

Not all hand sealers are created equal. You’ll find various models that cater to different sealing needs, temperatures, and types of packaging materials. Understanding these differences helps ensure you’re making the best investment for your unique requirements.

3.1 Impulse Hand Sealers

- Overview: Often the top choice for light to medium-duty tasks.

- Operation: Delivers a brief pulse of heat only when the sealing arm is pressed down.

- Advantages:

- Minimal power consumption.

- Quick heat-up and cool-down times.

- Easy to operate even for beginners.

- Best For: Sealing polyethylene, polypropylene, and other thermoplastic materials commonly found in retail packaging, food storage, and general use.

3.2 Constant Heat Hand Sealers

- Overview: Known for consistently applying heat along the sealing bar.

- Operation: Heating elements remain hot as long as the machine is powered on.

- Advantages:

- Ideal for thicker or more complex materials that require sustained heat.

- Offers strong, durable seals.

- Best For: Laminated film, Mylar bags, foil pouches, and other thicker packaging materials used in industrial and pharmaceutical applications.

3.3 Portable Hand Sealers

- Overview: Lightweight, sometimes even battery-operated devices perfect for mobile or on-the-go sealing.

- Operation: Typically an impulse-type system but scaled down for portability.

- Advantages:

- Convenient for sealing items outdoors or in tight spaces.

- Compact and easy to store.

- Best For: Small craft businesses, traveling sales, or household tasks.

3.4 Specialty Hand Sealers

- Overview: These are specialized devices designed for niche applications, such as medical-grade sealers or sealers that incorporate cutters.

- Operation: Varies depending on the specific function—some might include an integrated cutter to trim excess plastic.

- Advantages:

- Tailored solutions for unique needs, like sterilized environments.

- Precision controls for specialized packaging.

- Best For: Medical and laboratory settings, or businesses requiring custom seals with branding or batch numbers.

4. Key Components and Features

Regardless of the type, most hand sealers share a few critical components:

- Sealing Arm or Bar: Houses the heating element.

- Heating Element (Wire or Ribbon): Transfers heat to the plastic material.

- Timer Dial: Allows you to set how long the heat is applied (commonly found in impulse sealers).

- Pressure Adjustment: Some advanced models allow you to fine-tune pressure.

- Indicator Lights: Provide visual cues when the seal is complete.

Additional Features to Look For

- Replaceable Teflon Strips: Protect the heating wire and prevent melted plastic from sticking.

- Adjustable Temperature Controls: Found primarily in constant heat sealers, letting you dial in the perfect temperature.

- Safety Mechanisms: Such as auto-shutoff to prevent overheating.

5. Advantages of Using a Hand Seal Machine

Why invest in a hand seal machine instead of relying on twist ties, zip locks, or other temporary closures? Consider these compelling benefits:

- Professional Presentation: A neat, heat-sealed bag reflects quality and instills customer confidence.

- Extended Shelf Life: By creating airtight, moisture-proof seals, perishable items stay fresh longer.

- Versatility: Easily accommodates different types of bags and materials, making it useful across multiple industries.

- Cost Efficiency: Saves money by reducing product waste and minimizing the need for more complex packaging equipment.

- User-Friendliness: Minimal training is required, and even novices can achieve high-quality seals quickly.

- Space-Saving: Hand sealers are compact enough to fit on a small workspace, making them ideal for tight production areas or home-based businesses.

6. Step-by-Step Guide: How to Use a Hand Seal Machine

Learning to use a hand seal machine effectively is straightforward, but following the right steps ensures consistent, high-quality results.

- Power On and Preheat (If Needed)

- For impulse sealers, no significant preheating is required; for constant heat sealers, allow a brief warm-up period.

- Set the Timer or Temperature

- Adjust the timer dial (on impulse sealers) or temperature knob (on constant heat sealers) based on the thickness of your packaging material.

- Position the Bag

- Place the open end of the bag across the sealing bar. Ensure it’s flat and wrinkle-free.

- Lower the Sealing Arm

- Press down firmly to engage the heating element. Most models have an indicator light that turns on when sealing is in progress.

- Wait for the Signal

- On impulse sealers, the light will go off once the seal is complete. For constant heat machines, keep track of sealing time manually or based on experience.

- Release and Inspect

- Lift the arm, remove the bag, and quickly check if the seal is even and fully closed. If you notice gaps, slightly increase the time or temperature, and try again.

- Cool Down

- Allow the newly sealed area to cool before applying stress. Also, remember to turn off the machine if you won’t be using it immediately (especially important for constant heat sealers).

Pro Tip: Practice makes perfect. Test a few sample bags to dial in the optimal settings for your material and sealing conditions.

7. Choosing the Right Materials and Bags

Even the best hand seal machine can struggle if you’re working with incompatible or poor-quality packaging materials. Consider the following guidelines:

- Polyethylene (PE) and Polypropylene (PP) Films: Work best with impulse sealers due to their lower melting temperatures.

- Laminated Films and Foils: Thicker materials often require constant heat for secure, leak-proof seals.

- Bag Thickness: Most machines can handle thicknesses from 2 mil to 8 mil. For especially thick materials, invest in a heavy-duty or specialty model.

- Food-Grade Standards: If packaging edible goods, ensure your bags meet FDA or local regulatory requirements.

8. Maintenance and Troubleshooting

Like any machine, a hand sealer requires routine upkeep to perform at its best.

Regular Maintenance

- Cleaning: Gently wipe down the sealing bar and Teflon strip after each use to remove melted plastic residue.

- Replacing the Heating Element: Over time, the wire or ribbon can degrade. Follow the manufacturer’s instructions for a quick swap.

- Inspecting the Teflon Cover: A damaged Teflon cover can cause seals to stick or burn. Replace if torn or discolored.

- Lubricating Moving Parts: Lightly lubricate pivot points to ensure smooth operation.

Common Issues and Fixes

- Weak or Incomplete Seals: Check your time/temperature setting, or replace a worn-out heating element.

- Overheating/Burning: Lower your timer or temperature setting. Also, verify that the Teflon strip is intact.

- Machine Won’t Heat: Inspect the fuse or internal wiring. If in doubt, consult a professional.

- Uneven Seals: Ensure the bag is placed flat. Check for damage or warping on the sealing bar.

9. Buying Guide: Factors to Consider

When searching for the perfect hand seal machine, it’s important to weigh multiple factors—beyond just cost and brand name.

9.1 Build Quality and Materials

- Metal Housing: Offers durability and better heat dissipation than plastic.

- Reputable Brands: They typically provide better warranties and robust construction.

9.2 Seal Width and Length

- Seal Width: Wider seals are stronger but also require more heat.

- Bag Width: Choose a machine that can handle the widest bag you plan to seal.

9.3 Temperature and Time Settings

- Impulse Sealers: Look for an adjustable timer dial.

- Constant Heat Sealers: Opt for precise temperature controls to handle various materials.

9.4 Budget and Warranty

- Entry-Level: Ideal for casual or light use—budget-friendly, but may lack advanced features.

- Professional-Grade: Cost more but often include longer warranties, better build quality, and advanced functionality.

Where to Buy

- Online Marketplaces: A wide range of options, including user reviews to guide your choice.

- Specialty Packaging Stores: In-person demonstrations and expert consultations can be invaluable.

- Manufacturer Websites: Direct purchase may offer additional support and extended warranties.

10. Real-World Applications

10.1 Small Businesses

For small businesses, particularly e-commerce stores handling products like handmade crafts, candles, or baked goods, a hand seal machine is a must-have. Not only does it lend a professional touch, but it also ensures items reach customers in pristine condition. Sealed packaging can help maintain freshness for baked goods and prevent tampering for cosmetics, enhancing brand reputation.

10.2 Home and Kitchen Use

Think beyond industrial or commercial applications. A hand seal machine can be a time-saver in your own kitchen. If you buy food items in bulk—like grains, nuts, or frozen produce—a quick seal keeps them fresher for longer. You can also portion out family meals in advance, minimizing food waste and saving money in the long run.

10.3 Industrial and Commercial Settings

Larger-scale operations—such as food processing plants, pharmaceutical companies, and electronics manufacturers—rely on specialized hand sealers for quality assurance. Even though they may incorporate automated sealing lines, having a hand seal machine on the side helps with smaller batches, rework tasks, or quick fixes on the production floor.

11. Expert Tips for Prolonged Machine Life

- Warm-Up Period: For constant heat sealers, allow a few minutes for the device to reach the correct operating temperature.

- Optimize Timer Settings: Continuously tweak the timer or temperature to adapt to different bag thicknesses—this prevents overheating.

- Store Safely: Keep your machine in a cool, dry place. Avoid stacking heavy items on top of it.

- Use Quality Replacement Parts: Cheap aftermarket wires or Teflon strips can compromise seal quality.

- Periodic Inspection: At least once a month, do a thorough check for frayed cords or bent sealing bars.

12. Common Mistakes to Avoid

- Oversealing: Applying too much heat can burn through your bag, rendering it unusable.

- Undersealing: Short sealing times produce weak or incomplete seals.

- Skipping Routine Maintenance: Neglecting a quick wipe-down after use can lead to buildup and degrade performance over time.

- Ignoring Machine Capacity: Using the same settings for very thick or very thin materials can result in inconsistent results.

- Not Testing Samples: Always run sample seals when working with a new bag size or type.

13. FAQs

Q1: Can a hand seal machine handle foil or Mylar bags?

Yes, but you’ll likely need a constant heat sealer, as these materials require sustained high temperatures. Always verify the machine’s specifications to ensure it’s suited for thicker materials.

Q2: Is it safe to seal food products with a hand sealer?

Absolutely. Hand seal machines are often used in food packaging. Just ensure the bags are food-grade and you follow safety guidelines like proper cleaning.

Q3: Do I need a special outlet or electrical setup?

Most hand sealers run on standard household voltage (110–120V in the U.S., 220–240V in many other countries). Always check the product manual to match it with your local power requirements.

Q4: How long do the seals typically last?

A properly made seal can be permanent. The longevity of the sealed product depends more on the bag’s material and storage conditions than on the sealing process itself.

Q5: How do I know what size hand sealer I need?

Choose a machine that can accommodate the widest bag you plan to seal. It’s often wise to go one size larger for future flexibility.

14. Conclusion and Next Steps

A hand seal machine is an indispensable tool for anyone—small business owner, home entrepreneur, or hobbyist—who values efficient, high-quality packaging. By providing airtight seals, it helps extend product shelf life, enhances presentation, and even cuts down on waste. Whether you opt for an impulse model for quick sealing sessions or a constant heat device for heavier-duty tasks, the right machine can truly elevate the way you package goods.

Before making your final decision, remember to consider the types of materials you’ll be sealing, the volume of your operation, and any specialized features you may need—such as adjustable temperature controls or built-in cutters. Look for brands with positive user reviews and solid warranties to ensure you’re making an investment that pays off in the long run. The more comfortable you become with your hand seal machine, the easier it will be to customize seals that meet your exact needs.

Ready to get started? Browse reputable online marketplaces or your local packaging supply stores for models that align with your requirements. Once you’ve found your ideal hand seal machine, begin experimenting with different bag types and sealing techniques. Perfect seals not only protect your products but also speak volumes about your attention to detail. Embrace the confidence that comes with professional, tamper-proof packaging and watch how it transforms both your workflow and customer satisfaction.

Get out there and seal those bags! If you have any questions or want to share your own hand seal machine tips, be sure to comment below, sign up for our newsletter, or explore our related resources. With the right machine in your hands, packaging becomes a breeze, and your products will always make a memorable first impression.

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.