The Ultimate Guide to Electrostatic Precipitators: How They Work, Benefits, and Applications

In today’s world, where industrialization is at its peak, air pollution has become a pressing concern. Factories, power plants, and manufacturing units release harmful particulate matter into the atmosphere, posing significant health and environmental risks.

One of the most effective technologies for controlling industrial air pollution is the Electrostatic Precipitator (ESP). Used across industries, ESPs help remove fine particles like dust, smoke, and soot from exhaust gases before they enter the environment.

This in-depth guide will explore everything you need to know about electrostatic precipitators—how they work, their benefits, types, applications, and why they are essential for industries aiming to meet environmental regulations.

Table of Contents

1. What is an Electrostatic Precipitator?

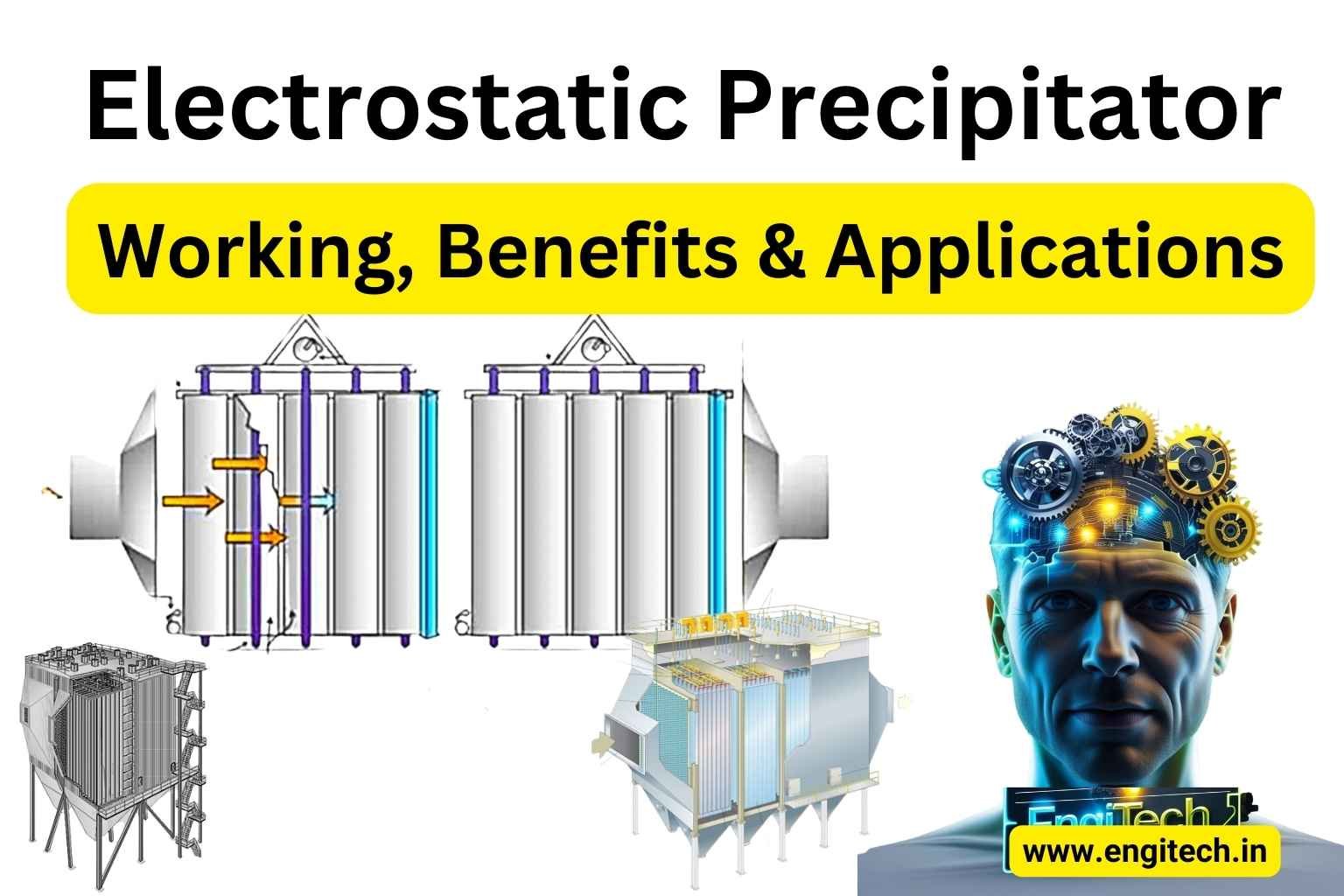

An Electrostatic Precipitator (ESP) is an advanced air pollution control device that removes fine particles from gas streams using electrostatic forces. ESPs are widely used in industries to filter out particulate matter (PM), smoke, and pollutants from industrial flue gases before they are released into the atmosphere.

Why Are ESPs Important?

- They reduce air pollution by removing up to 99% of particulate matter.

- Help industries comply with environmental regulations.

- Improve workplace safety by minimizing toxic airborne particles.

- Prevent damage to downstream equipment by reducing dust accumulation.

2. How Does an Electrostatic Precipitator Work?

Step-by-Step Working Principle

- Charging the Particles

- The ESP introduces a high-voltage electrostatic field.

- Pollutant particles in the exhaust gas become negatively charged as they pass through ionized air.

- Collection of Particles

- The negatively charged particles are attracted to positively charged collector plates inside the ESP.

- Particles stick to the plates, forming a layer of dust.

- Particle Removal

- Collected particles are periodically removed from the plates using rappers or shakers.

- The collected dust falls into a hopper for disposal or recycling.

Key Components of an ESP

- Discharge Electrodes – Create an electrostatic field to charge particles.

- Collector Plates – Capture and hold charged particles.

- Rappers or Vibrators – Dislodge accumulated particles from plates.

- Hopper – Collects the removed particulate matter for disposal.

- Power Supply – Provides high-voltage electricity to charge particles.

3. Types of Electrostatic Precipitators

Electrostatic precipitators are categorized based on their design and operational method:

A. Dry Electrostatic Precipitators (Dry ESP)

- Most commonly used in power plants, cement plants, and steel mills.

- Handles dry, non-sticky particulate matter.

- Uses mechanical rapping systems to remove collected dust.

B. Wet Electrostatic Precipitators (Wet ESP)

- Used in chemical plants, petroleum refineries, and industries dealing with sticky or wet particles.

- Uses water spray to remove collected particles from collector plates.

- Effective for removing acid mist, heavy metals, and sticky pollutants.

C. Plate-Type Electrostatic Precipitators

- Consists of vertical collection plates with high-voltage discharge wires.

- Commonly used in power generation and industrial applications.

D. Tubular Electrostatic Precipitators

- Uses cylindrical collection surfaces instead of plates.

- Best suited for low-flow applications such as smokestacks, chemical plants, and oil mist filtration.

4. Advantages of Using Electrostatic Precipitators

✔ High Efficiency – Removes up to 99% of airborne particles.

✔ Cost-Effective in the Long Run – Though the initial investment is high, operational costs are low.

✔ Handles Large Volumes of Gas – Suitable for high-capacity industrial applications.

✔ Low Pressure Drop – Unlike bag filters, ESPs do not create significant airflow resistance.

✔ Capable of Capturing Fine Particles – Can remove particles as small as 0.01 microns.

✔ Reduces Health Hazards – Helps industries minimize respiratory illnesses among workers.

5. Applications and Industries That Use ESPs

Electrostatic precipitators are widely used in industries that generate airborne pollutants. Some key applications include:

A. Power Plants

- Used in coal-fired power plants to capture fly ash and other pollutants from exhaust gases.

B. Cement Industry

- Controls dust emissions during clinker cooling, raw material grinding, and kiln operations.

C. Steel & Metal Processing

- Removes metallic dust and fumes from blast furnaces and metal refining plants.

D. Petrochemical & Oil Refineries

- Helps eliminate oil mist, acid mists, and VOCs.

E. Woodworking & Pulp and Paper Industry

- Controls sawdust, paper dust, and wood particles from manufacturing plants.

6. Comparison: Electrostatic Precipitator vs. Other Air Pollution Control Technologies

| Feature | Electrostatic Precipitator (ESP) | Baghouse Filters | Cyclone Separators | Scrubbers |

| Efficiency | Up to 99% removal | 95-99% | 70-90% | 90-99% |

| Particle Size | Removes fine particles (0.01 microns) | 0.3 microns+ | Larger particles only | Varies |

| Maintenance | Low | High | Low | Medium |

| Operating Cost | Low | Medium | Low | Medium |

| Best For | High-volume dust | Fine dust particles | Large debris | Wet and gaseous pollutants |

7. Challenges and Limitations of ESPs

While ESPs are highly effective, they do have some drawbacks:

- High Initial Cost – Expensive to install, though long-term savings compensate.

- Not Effective for Gaseous Pollutants – Only removes particulate matter, not gases.

- Performance Depends on Particle Properties – Sticky or wet particles require a wet ESP.

8. Maintenance and Efficiency Optimization

To ensure long-term performance:

- Regularly inspect electrodes and plates for wear.

- Clean collector plates periodically.

- Monitor power supply to maintain optimal charging efficiency.

9. The Future of Electrostatic Precipitators

- Smart ESPs with IoT and AI-driven monitoring.

- Hybrid ESPs combining multiple filtration technologies.

- Nanotechnology advancements to capture even smaller particles.

General FAQs

- What is an Electrostatic Precipitator (ESP)?

An Electrostatic Precipitator (ESP) removes particulate matter from industrial exhaust gases using electrostatic forces. - How does an Electrostatic Precipitator work?

An Electrostatic Precipitator charges dust particles in flue gas and collects them on oppositely charged plates, ensuring cleaner emissions. - What are the main components of an Electrostatic Precipitator?

An Electrostatic Precipitator consists of discharge electrodes, collection plates, hoppers, rappers, and a power supply unit. - What are the different types of Electrostatic Precipitators?

Industries use dry ESPs for non-sticky dust and wet ESPs for high-humidity applications to remove fine particulate matter. - Which industries use Electrostatic Precipitators?

Power plants, cement factories, steel plants, and paper mills use Electrostatic Precipitators to control air pollution.

Performance & Efficiency

- How efficient is an Electrostatic Precipitator in removing dust?

An Electrostatic Precipitator can achieve 99% efficiency, depending on the particle size, flue gas composition, and ESP design. - What factors affect the efficiency of an Electrostatic Precipitator?

The flue gas temperature, particle resistivity, voltage level, and electrode alignment directly impact ESP efficiency. - How does an ESP compare to other air pollution control devices?

Unlike bag filters and scrubbers, ESPs handle large gas volumes efficiently while requiring less maintenance. - Can an Electrostatic Precipitator remove harmful gases?

An Electrostatic Precipitator primarily removes solid particulates but does not eliminate gases like NOx or SO2 without additional scrubbers. - What is the lifespan of an Electrostatic Precipitator?

With proper maintenance, an ESP can last 15–25 years, making it a long-term solution for air pollution control.

Maintenance & Cost

- How often should an Electrostatic Precipitator be cleaned?

Industries clean ESPs regularly, using rappers or sonic horns to dislodge accumulated dust and maintain efficiency. - What are common problems in Electrostatic Precipitators?

Voltage fluctuations, electrode misalignment, excessive dust buildup, and poor rapping mechanisms can reduce ESP performance. - How much does an Electrostatic Precipitator cost?

The cost of an ESP varies based on size, capacity, and industrial application, ranging from $100,000 to several million dollars.

Regulations & Environmental Impact

- Are Electrostatic Precipitators environmentally friendly?

Electrostatic Precipitators significantly reduce particulate emissions, helping industries comply with environmental regulations like EPA and CPCB norms. - What are the latest advancements in Electrostatic Precipitator technology?

Modern ESPs feature high-frequency power supplies, AI-based monitoring, and hybrid designs to improve efficiency and compliance.

Conclusion & Key Takeaways

Electrostatic precipitators are a powerful solution for industrial air pollution control, providing high efficiency and cost-effectiveness. Whether in power plants, cement factories, or steel industries, ESPs play a crucial role in maintaining environmental standards.

💡 Want to improve your industrial air filtration system? Contact us today for customized ESP solutions.