Drum dryers, also known as rotary dryers, play a vital role in various industries, providing an efficient and effective method for drying a wide range of materials. This blog post will delve into the working principles of drum dryers, illustrated with a detailed diagram, and discuss their diverse uses. Our focus will be on answering key questions related to drum dryer (rotary dryer) diagrams and uses.

Questions This Blog Will Answer:

- What is the diagram of a drum dryer (rotary dryer)?

- What are the primary uses of drum dryers (rotary dryers)?

Drum Dryer (Rotary Dryer) Diagram

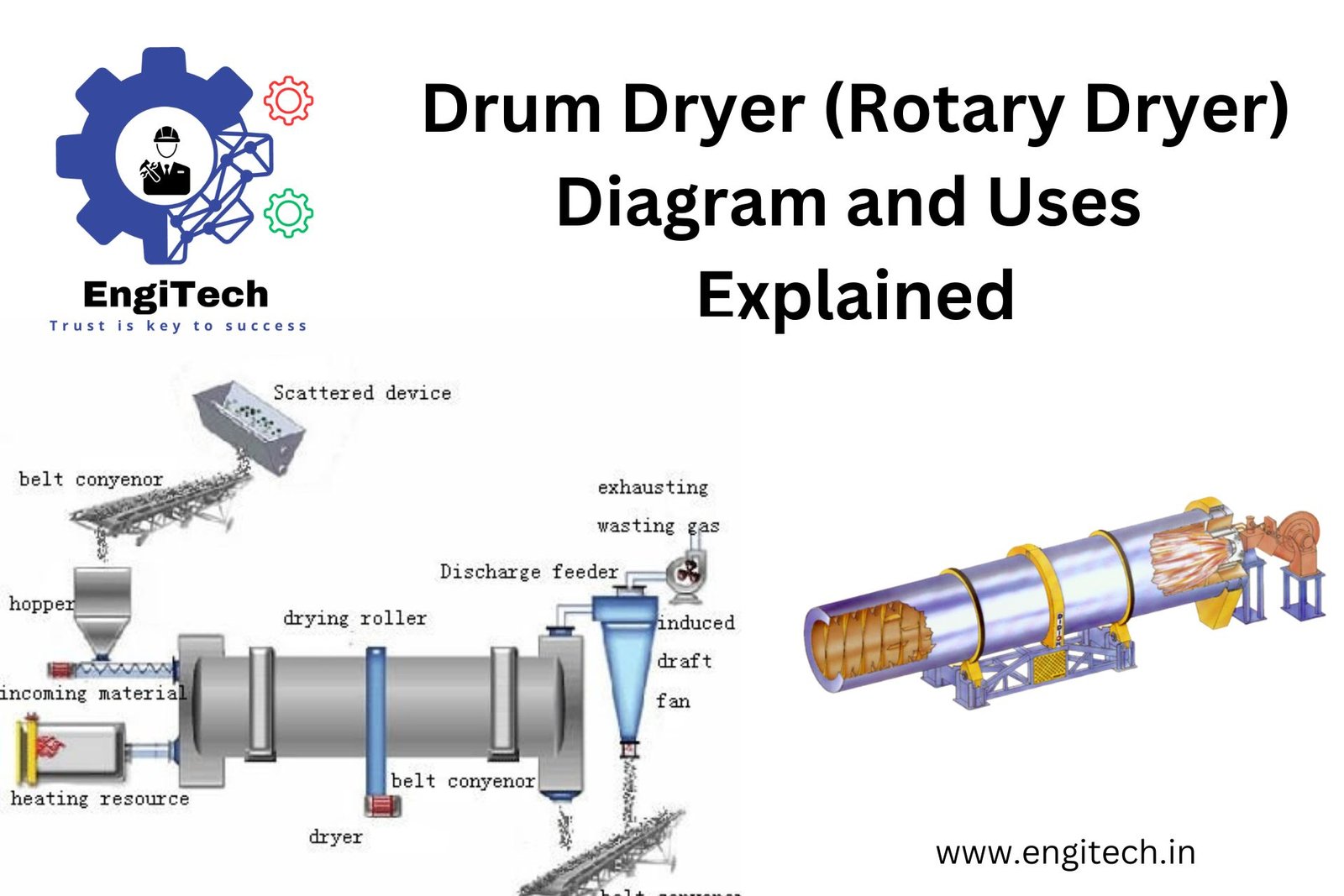

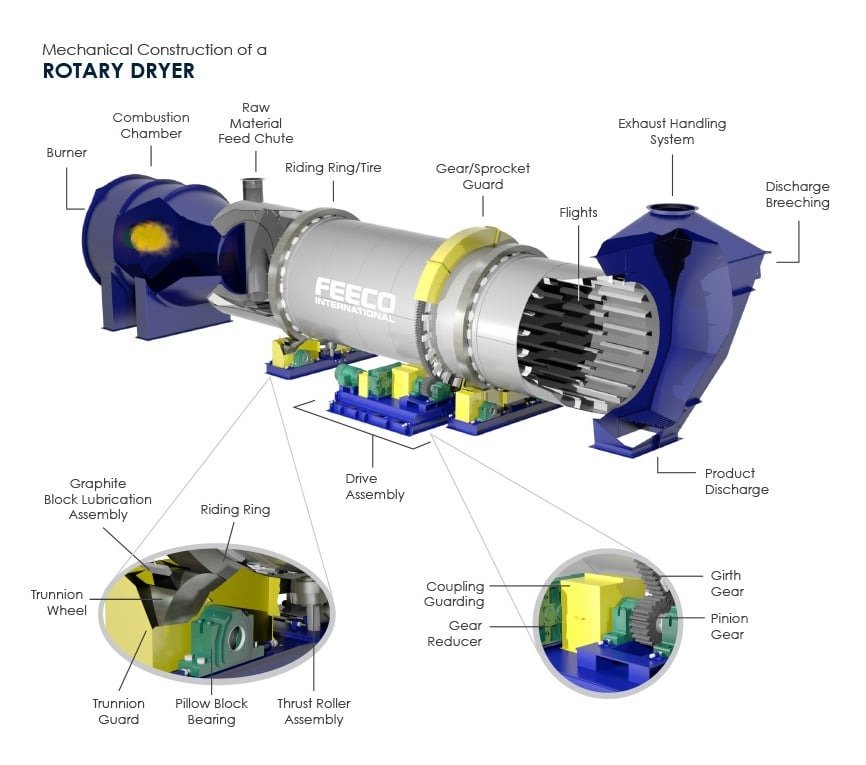

A drum dryer (rotary dryer) consists of several key components that work together to ensure efficient drying of materials. Below is a detailed diagram of a typical drum dryer:

- Feed Hopper: Introduces wet material into the drum. The hopper ensures a steady and controlled flow of material into the dryer.

- Rotating Drum: The primary component where the drying process occurs. The drum rotates to facilitate the movement and tumbling of the material.

- Heat Source: Provides the necessary heat for drying. The heat source can be burners, heat exchangers, or steam. It can utilize natural gas, propane, oil, or other fuels.

- Hot Air Inlet: Introduces hot air or gas into the drum. This hot air stream is crucial for transferring heat to the material.

- Exhaust System: Removes moisture-laden air from the drum. It typically includes filters to capture fine particles and ensure a clean operation.

- Discharge End: Where the dried material exits the drum. This end is designed to collect the dried product efficiently.

- Support Structure: Ensures the stability and rotation of the drum. The structure must be robust to handle the continuous operation and weight of the drum and materials.

Primary Uses of Drum Dryers

Drum dryers are versatile and find applications across various industries due to their ability to handle different types of materials. Here are some primary uses:

- Food Processing:

- Drying Grains and Cereals: Drum dryers are used to reduce the moisture content in grains and cereals, enhancing their shelf life and quality.

- Dehydrating Fruits and Vegetables: They efficiently dry fruits and vegetables, preserving their nutrients and flavor while extending shelf life.

- Producing Powdered Milk and Coffee: Drum dryers are critical in producing dry milk powder and instant coffee, ensuring consistency and quality.

- Pharmaceuticals:

- Drying Active Pharmaceutical Ingredients (APIs): Drum dryers help in achieving the desired moisture content in APIs, ensuring their stability and efficacy.

- Drying Excipients: They also dry excipients, which are essential components in tablets and capsules.

- Chemicals:

- Drying Powders and Granules: Drum dryers dry chemical powders and granules, enhancing their stability and preventing caking.

- Enhancing Product Stability: The controlled drying process ensures that the chemical properties of the materials remain intact.

- Mining:

- Drying Ores and Minerals: Drum dryers are used to dry ores and minerals, making them easier to handle and process further.

- Drying Coal: They help reduce the moisture content in coal, improving its combustion efficiency and reducing transportation costs.

- Construction:

- Drying Sand and Cement: Drum dryers dry sand and cement used in construction, ensuring they are in optimal condition for mixing and application.

- Drying Asphalt: They are also used in drying asphalt for road construction, ensuring it has the right consistency and moisture content.

Conclusion

Drum dryers (rotary dryers) are indispensable tools in many industries due to their efficiency, versatility, and scalability. By understanding their diagrams and applications, businesses can optimize their drying processes and improve product quality. As technology advances, drum dryers will continue to evolve, offering even greater efficiency and sustainability.

For more in-depth articles and resources on industrial drying technologies and innovations, visit EngiTech.in. Stay updated on the latest advancements and applications in the industry!