Custom Air Handling Units: A Comprehensive Guide to Design, Efficiency, and Customization

In industrial settings, maintaining air quality, temperature, and humidity is essential for both comfort and safety. One key component that helps achieve these conditions is the Custom Air Handling Unit (AHU). Standard AHUs may not always meet the unique requirements of industrial applications, making customized solutions necessary. This blog post will explore the design, functionality, and benefits of custom air handling units, providing a detailed guide for professionals seeking a tailored solution for their facilities.

Table of Contents

1. Introduction to Custom Air Handling Units

A custom air handling unit is a mechanical system designed to regulate and circulate air in a building or an industrial environment. Unlike off-the-shelf solutions, custom AHUs are tailored to meet specific needs such as unique airflow requirements, space constraints, or specialized filtration systems. These units often include features like variable-speed fans, energy recovery systems, and advanced controls that allow for superior customization and performance.

The customization of an AHU ensures that it is optimized for both the environment in which it operates and the industry it serves. Whether you are dealing with pharmaceutical cleanrooms, industrial manufacturing, or large commercial spaces, a custom AHU offers the flexibility and efficiency required to maintain precise control over air quality.

2. Why Choose a Custom Air Handling Unit?

Choosing a custom air handling unit provides several advantages over standardized solutions, particularly when complex or industry-specific requirements are involved. Here are some reasons why industries prefer custom solutions:

- Tailored Performance: With a custom AHU, you can specify the exact temperature, humidity control, and airflow required for your application.

- Space Efficiency: In facilities with space constraints, custom designs ensure that the AHU fits seamlessly into the building’s architecture.

- Enhanced Air Quality: Specialized filters, UV light systems, and HEPA filters can be integrated to meet strict air quality standards.

- Energy Efficiency: Custom units often include energy-saving features like heat recovery wheels, variable-speed drives, and advanced controls to optimize energy usage.

- Durability: Custom-built units are often designed to withstand harsher environmental conditions or specific operational needs, increasing the lifespan of the equipment.

3. Key Components of a Custom Air Handling Unit

Understanding the key components of an AHU helps in appreciating the customization possibilities. Here are the essential parts of a custom air handling unit:

- Fan Section: Fans are responsible for air movement. Custom AHUs can include variable-speed fans, which adjust the airflow based on real-time requirements, reducing energy consumption.

- Filter Section: The type of filter used in the AHU can be customized depending on the required air quality. HEPA filters, activated carbon filters, or UV light disinfection systems can be incorporated to remove contaminants.

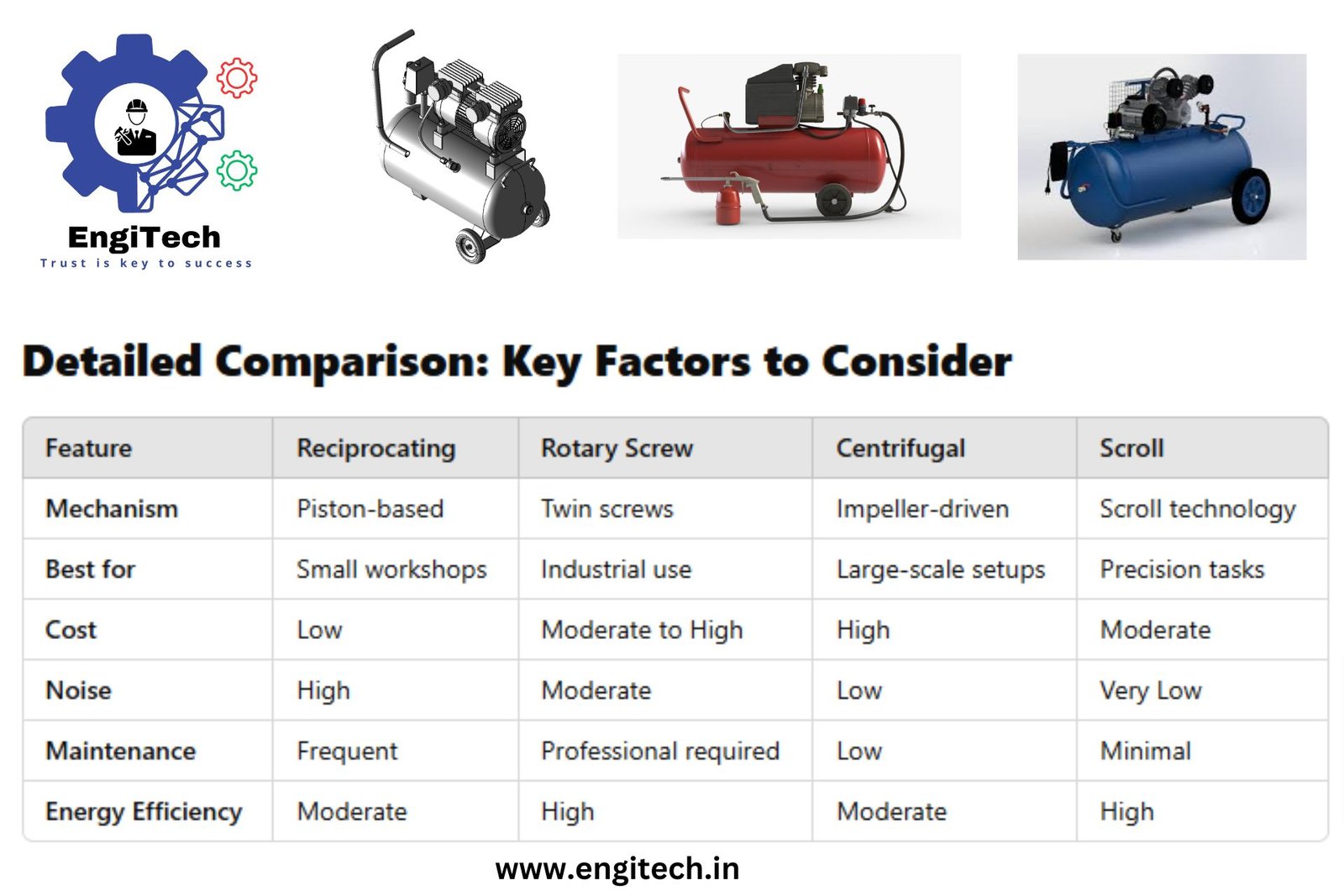

- Cooling and Heating Coils: These coils regulate the temperature of the air. The size and material of the coils can be customized based on thermal loads and specific application requirements.

- Humidifiers/Dehumidifiers: Humidity control is crucial in many industrial settings, especially in manufacturing or healthcare environments.

- Heat Recovery Systems: Energy recovery wheels or plates can be integrated to reclaim energy from exhaust air, enhancing the overall efficiency of the AHU.

- Control Systems: Custom control systems allow for advanced monitoring and automation, including integration with Building Management Systems (BMS).

4. Designing a Custom AHU: What to Consider

When designing a custom air handling unit, several factors should be considered to ensure optimal performance. These considerations include:

a. Airflow Requirements

The required airflow rate is the most important factor in AHU design. The airflow must be sufficient to ventilate the space while maintaining comfort and safety. Custom AHUs allow for precise airflow control, which is critical in environments like cleanrooms or labs.

b. Space Constraints

The size of the AHU must be tailored to fit the available space. Custom AHUs can be designed to fit into compact or irregular spaces without compromising performance.

c. Environmental Conditions

Consider the external environment in which the AHU will operate. For outdoor installations, units must be weatherproof and resistant to corrosion. Harsh industrial environments may require additional protection from dust, chemicals, or extreme temperatures.

d. Energy Efficiency

Energy consumption is a key concern in AHU operation. Selecting energy-efficient components, such as variable-speed fans, high-efficiency motors, and heat recovery systems, will significantly reduce operating costs.

e. Air Quality Standards

Certain industries, such as pharmaceuticals or food processing, have strict air quality requirements. Custom AHUs can incorporate advanced filtration and disinfection technologies to meet or exceed these standards.

5. Energy Efficiency in Custom AHUs

Energy efficiency is a top priority for most industries due to rising energy costs and environmental regulations. Here are some ways custom air handling units improve energy efficiency:

a. Variable-Speed Fans

Traditional AHUs use constant-speed fans, which operate at full power regardless of the actual demand. In contrast, custom AHUs with variable-speed fans adjust the airflow based on current needs, reducing energy consumption during low-demand periods.

b. Heat Recovery Systems

Heat recovery is another key feature that enhances energy efficiency. Custom AHUs can be equipped with energy recovery wheels or plates, which transfer heat from exhaust air to incoming fresh air. This process reduces the energy required to heat or cool the air, cutting down operational costs.

c. Smart Controls

Custom control systems allow for precise monitoring and adjustment of air handling unit operations. Features such as CO2 sensors, humidity sensors, and temperature sensors ensure that the AHU only operates at full capacity when necessary, reducing energy wastage.

6. Applications of Custom Air Handling Units in Industrial Settings

Custom air handling units are used across various industries to meet specific environmental and operational requirements. Some common applications include:

- Pharmaceutical and Cleanroom Facilities: These industries require stringent air quality control to prevent contamination. Custom AHUs equipped with HEPA filters and humidity control are essential for maintaining sterile conditions.

- Manufacturing Plants: In industries like automotive or electronics, air quality control is essential for both employee safety and product quality. Custom AHUs help regulate temperature and humidity while filtering out harmful contaminants.

- Hospitals and Healthcare Facilities: Custom AHUs with specialized filtration systems are crucial for maintaining a sterile environment and preventing the spread of airborne pathogens.

- Data Centers: Efficient cooling is a critical requirement for data centers. Custom AHUs can be designed to handle the high cooling demands while minimizing energy consumption.

7. Selecting the Right Custom AHU Manufacturer

Choosing the right manufacturer for your custom air handling unit is a critical decision. Here are some factors to consider when selecting a manufacturer:

- Industry Experience: Look for manufacturers with experience in your industry. They will be more familiar with the specific challenges and requirements of your application.

- Customization Capabilities: Ensure that the manufacturer can offer full customization, from design to component selection.

- Energy Efficiency Expertise: Manufacturers with a focus on energy efficiency will help you create a more sustainable and cost-effective solution.

- After-Sales Support: Reliable after-sales support, including maintenance and repair services, is essential to ensure the longevity of your custom AHU.

8. Maintenance and Longevity of Custom AHUs

Regular maintenance is essential for the long-term performance and efficiency of custom air handling units. Key maintenance tasks include:

- Filter Replacement: Filters should be inspected and replaced regularly to maintain air quality.

- Fan and Motor Inspections: Regularly inspect fans and motors for wear and tear. Lubricate bearings and replace any damaged parts to ensure smooth operation.

- Coil Cleaning: Clean heating and cooling coils to maintain efficient heat exchange.

- Control System Calibration: Periodically calibrate control systems to ensure accurate monitoring and control of air handling functions.

By adhering to a regular maintenance schedule, you can extend the lifespan of your custom AHU and ensure it operates at peak efficiency.

9. Conclusion: Elevating Air Quality with Custom AHUs

Investing in a custom air handling unit provides numerous benefits, including tailored performance, energy efficiency, and improved air quality. By carefully considering factors such as airflow, space constraints, and energy efficiency, you can design a custom solution that meets the specific needs of your industrial facility. With the right manufacturer and proper maintenance, a custom AHU can enhance operational efficiency, reduce energy costs, and improve the working environment.

Frequently asked questions (FAQs) about Custom Air Handling Units:

- What is a custom air handling unit and how does it differ from a standard AHU?

A custom air handling unit is designed to meet specific airflow, temperature, and filtration needs, offering tailored performance, unlike standard AHUs, which are built for more generalized applications. - How do I determine the right size for my custom air handling unit?

You can determine the right size for your custom AHU by considering your building’s specific airflow requirements, space constraints, and the environmental conditions in which the unit will operate. - What components can be customized in an air handling unit?

You can customize several components in an AHU, including fan speed, filtration systems, heating and cooling coils, humidifiers, heat recovery systems, and control systems. - How does a custom air handling unit improve energy efficiency?

A custom AHU improves energy efficiency by incorporating features like variable-speed fans, heat recovery systems, and smart controls that adjust operations based on demand, minimizing energy consumption. - What industries benefit the most from custom air handling units?

Industries like pharmaceuticals, healthcare, manufacturing, cleanroom environments, and data centers benefit the most from custom AHUs due to their specific air quality, temperature, and humidity control needs.

If you’re ready to explore the possibilities of a custom air handling unit for your facility, contact our experts at EngiTech today to get started. We provide comprehensive resources and the latest innovations in industrial drying and air handling technology.