Choosing the right air compressor can be overwhelming, given the wide variety of options available. Four popular types—reciprocating, rotary screw, centrifugal, and scroll compressors—serve different purposes, each with its unique features and advantages. This blog provides a detailed comparison of these air compressor types, helping you identify the best option for your needs.

Whether you’re working on a DIY project, managing an industrial operation, or need equipment for specialized applications, understanding these air compressors will guide you toward a more informed decision.

Understanding the Basics of Air Compressors

An air compressor converts power into potential energy stored in pressurized air, enabling a wide range of applications. The core difference among compressor types lies in their mechanism of compressing air, capacity, and use cases. Let’s explore each type in detail.

1. Reciprocating Air Compressors

What Are Reciprocating Air Compressors?

Reciprocating air compressors, also known as piston compressors, are one of the most common types. They operate using a piston inside a cylinder that moves back and forth to compress air.

Key Features

- Mechanism: Utilizes pistons and crankshafts.

- Pressure Output: High-pressure output, making it ideal for small-scale industrial and personal use.

- Configuration: Available in single-stage and multi-stage versions.

Advantages

- Cost-Effective: Affordable initial investment compared to other compressor types.

- High Pressure: Suitable for applications requiring high-pressure air.

- Compact Design: Ideal for small setups.

Disadvantages

- Noisy Operation: Not ideal for noise-sensitive environments.

- Lower Efficiency: Less suitable for continuous, heavy-duty operations.

- High Maintenance: Requires frequent checks and lubrication.

Best Applications

- Workshops and garages.

- Inflating tires and operating small tools.

- Light manufacturing operations.

2. Rotary Screw Air Compressors

What Are Rotary Screw Air Compressors?

Rotary screw compressors are widely used in industrial settings for their efficiency and reliability. These compressors use two interlocking helical screws to compress air continuously.

Key Features

- Mechanism: Uses dual rotors for continuous compression.

- Design: Often oil-cooled, though oil-free models are available.

- Capacity: High airflow, suitable for large-scale applications.

Advantages

- Continuous Operation: Designed for 24/7 use without overheating.

- Quiet Performance: Operates with minimal noise compared to reciprocating compressors.

- Energy Efficiency: High output with lower energy consumption over time.

Disadvantages

- Higher Initial Cost: More expensive upfront investment.

- Complex Maintenance: Requires professional servicing for parts like screws and oil separators.

Best Applications

- Industrial manufacturing.

- Construction sites.

- Powering large pneumatic tools.

3. Centrifugal Air Compressors

What Are Centrifugal Air Compressors?

Centrifugal compressors are high-capacity machines that use a rotating impeller to accelerate and pressurize air. These compressors are typically used in large industrial operations.

Key Features

- Mechanism: Employs centrifugal force for compression.

- Design: Oil-free operation and minimal moving parts.

- Capacity: Designed for high airflow and pressure.

Advantages

- Durable Design: Minimal wear due to fewer moving parts.

- Oil-Free Operation: Ensures clean, uncontaminated air.

- Scalability: Suitable for operations requiring large volumes of compressed air.

Disadvantages

- Complex Setup: Requires skilled installation and maintenance.

- High Cost: Expensive both initially and operationally.

Best Applications

- Petrochemical and power generation industries.

- Large-scale HVAC systems.

- High-volume manufacturing processes.

4. Scroll Air Compressors

What Are Scroll Air Compressors?

Scroll compressors use two spiral-shaped scrolls, one stationary and one moving, to compress air. They are known for their quiet operation and compact design.

Key Features

- Mechanism: Utilizes scroll technology for smooth, continuous compression.

- Design: Compact, lightweight, and oil-free.

- Performance: Ideal for low-capacity, high-precision tasks.

Advantages

- Quiet Operation: Extremely low noise levels.

- Low Maintenance: Fewer moving parts reduce maintenance needs.

- Energy Efficiency: Consumes less power for light-duty tasks.

Disadvantages

- Limited Capacity: Not suitable for heavy-duty industrial use.

- Higher Cost: Expensive for the performance range it offers.

Best Applications

- Medical and dental equipment.

- Laboratory environments.

- Electronics manufacturing.

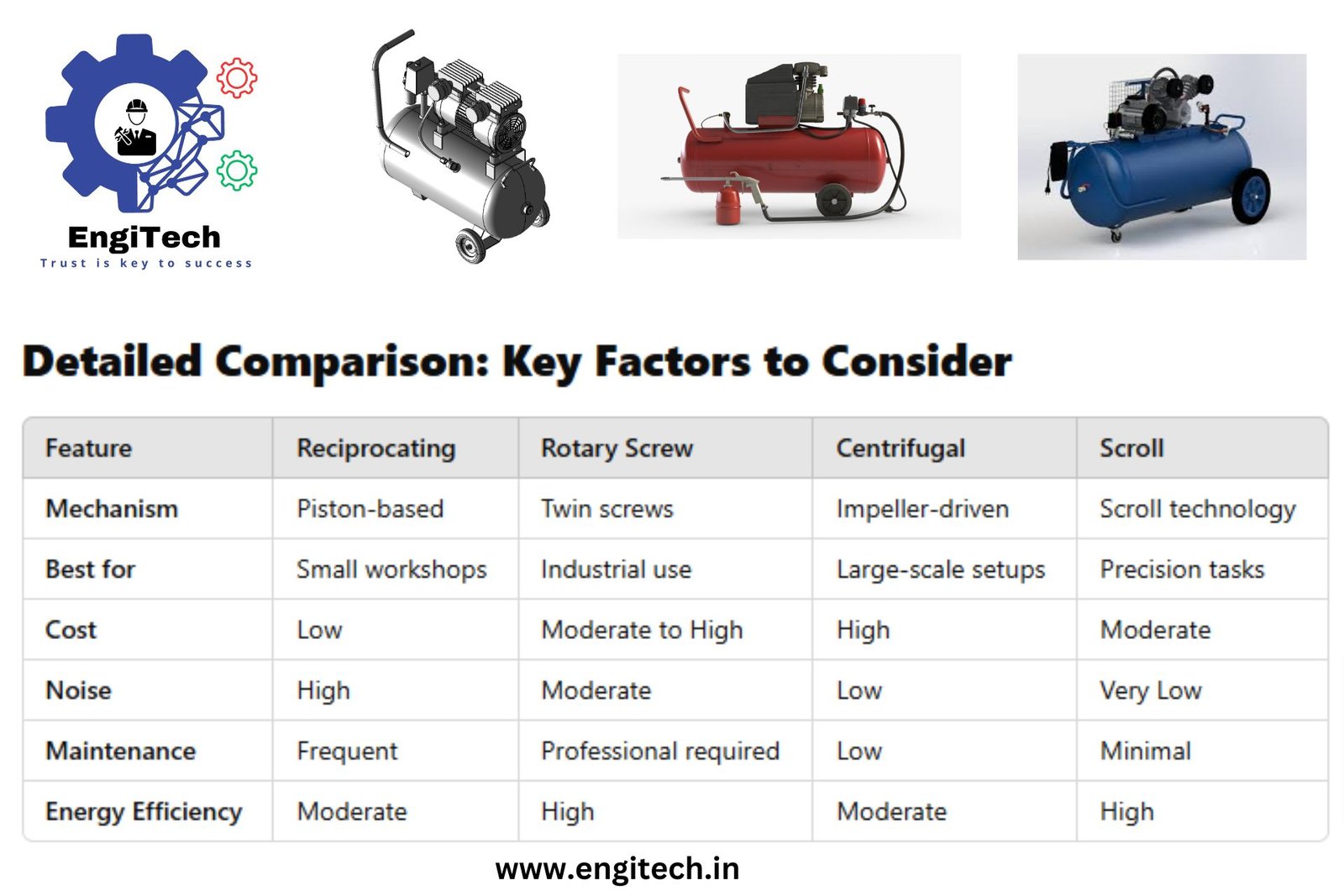

Detailed Comparison: Key Factors to Consider

| Feature | Reciprocating | Rotary Screw | Centrifugal | Scroll |

|---|---|---|---|---|

| Mechanism | Piston-based | Twin screws | Impeller-driven | Scroll technology |

| Best for | Small workshops | Industrial use | Large-scale setups | Precision tasks |

| Cost | Low | Moderate to High | High | Moderate |

| Noise | High | Moderate | Low | Very Low |

| Maintenance | Frequent | Professional required | Low | Minimal |

| Energy Efficiency | Moderate | High | Moderate | High |

How to Choose the Right Air Compressor

1. Assess Your Needs

Determine the primary application of the air compressor—whether it’s for light-duty DIY projects, industrial manufacturing, or large-scale operations.

2. Consider the Environment

Think about where you’ll use the compressor. If noise is a concern, prioritize rotary screw or scroll compressors. For outdoor or industrial use, reciprocating and centrifugal models may be more suitable.

3. Evaluate the Budget

While initial costs vary, consider long-term operational expenses, including maintenance and energy consumption.

4. Look at Airflow Requirements

Match the compressor’s CFM and PSI ratings to the tools and machinery you’ll power.

Conclusion: Choosing the Right Air Compressor for Your Needs

Reciprocating, rotary screw, centrifugal, and scroll air compressors all have their unique strengths, making them suited for specific applications. By understanding their features, advantages, and limitations, you can choose a model that perfectly fits your requirements.

Ready to dive deeper into the world of air compressors? Visit EngiTech for more expert resources, industry trends, and buying guides!