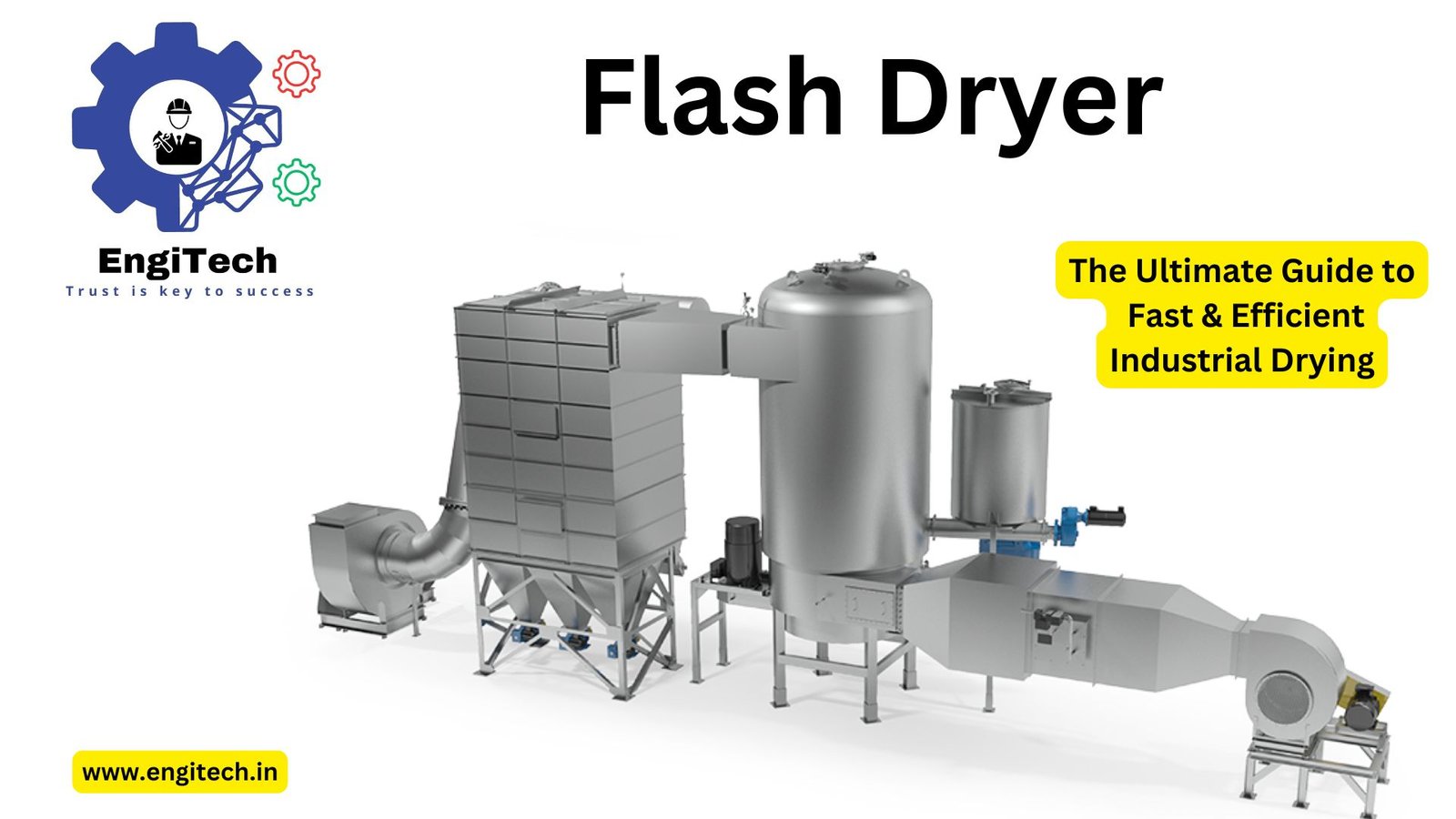

Flash Dryer: The Ultimate Guide to Efficient Industrial Drying

In the fast-paced world of industrial drying, flash dryers have emerged as a leading solution for businesses seeking efficient and cost-effective methods to process materials. Whether you’re handling powders, granules, or even heat-sensitive products, flash dryers provide the perfect blend of speed, efficiency, and versatility.

This blog will walk you through the key features, working principles, advantages, and applications of flash dryers, making it your go-to resource for understanding this revolutionary technology. Let’s explore how this dryer can transform your industrial operations and help you achieve optimal productivity.

Table of Contents

What is a Flash Dryer?

A flash dryer is a drying system designed to remove moisture from various materials using a stream of hot air. The material is introduced into the dryer through a feed mechanism and is instantly exposed to the high-velocity hot air. This rapid drying process ensures minimal exposure to heat, preserving the quality of the material.

How Does a Flash Dryer Work?

1. Material Feeding

The wet material is fed into the flash dryer using a screw feeder or other specialized feeding systems, ensuring a steady and controlled input.

2. Hot Air Supply

A high-velocity air stream is generated by heating systems like burners or steam. The air temperature and velocity are carefully controlled depending on the material properties.

3. Drying Chamber

As the material enters the drying chamber, it is suspended in the hot air stream. The rapid movement ensures maximum surface area exposure, leading to quick and uniform drying.

4. Separation and Collection

Dried particles are separated from the air stream using cyclones or bag filters. The final product is collected, while the moisture-laden air is expelled.

Key Features of Flash Dryers

- Rapid Drying: Achieves drying within seconds, making it ideal for time-sensitive operations.

- Versatility: Can handle a wide range of materials, from powders to heat-sensitive products.

- Energy Efficiency: Optimized airflow reduces energy consumption compared to traditional drying methods.

- Compact Design: Requires minimal floor space, making it suitable for facilities with space constraints.

Advantages of Using a Flash Dryer

1. Cost-Effectiveness

The energy-efficient design ensures reduced operational costs, making it a preferred choice for industrial drying.

2. Preservation of Material Quality

The short drying time minimizes thermal degradation, preserving the integrity of heat-sensitive materials.

3. Ease of Operation

Flash dryers are user-friendly and require minimal maintenance, ensuring seamless operations.

4. Scalability

Available in various sizes, flash dryers can be tailored to suit small-scale or large-scale industrial needs.

Applications of Flash Dryers

1. Food Processing

Used for drying ingredients like starch, spices, and dairy products.

2. Chemical Industry

Efficient for drying chemicals, fertilizers, and synthetic resins.

3. Pharmaceuticals

Ideal for drying active pharmaceutical ingredients (APIs) and other delicate compounds.

4. Minerals and Ores

Used for drying kaolin, gypsum, and other minerals.

Choosing the Right Flash Dryer for Your Needs

When selecting a flash dryer, consider the following factors:

- Material Properties: Moisture content, particle size, and heat sensitivity.

- Throughput Requirements: The volume of material to be dried per hour.

- Energy Source: Availability of gas, electricity, or steam for heating.

- Space Constraints: Ensure the dryer fits within your facility’s layout.

Maintenance Tips for Optimal Performance

- Regular Cleaning: Prevents material build-up in the drying chamber.

- Inspection of Components: Check air filters, fans, and feed systems for wear and tear.

- Monitor Air Temperature: Ensure consistent drying performance by maintaining optimal temperature levels.

- Replace Worn Parts: Regularly replace seals, gaskets, and other critical components.

Flash Dryers vs. Other Drying Methods

| Feature | Flash Dryer | Rotary Dryer | Spray Dryer |

|---|---|---|---|

| Drying Time | Very Short (seconds) | Long (minutes) | Moderate (seconds) |

| Space Requirement | Compact | Large | Moderate |

| Material Versatility | High | Medium | High |

| Energy Efficiency | High | Moderate | Moderate |

Future Trends in Flash Drying Technology

With advancements in automation and energy efficiency, flash dryers are becoming smarter and more sustainable. Features like IoT integration for real-time monitoring and AI-driven performance optimization are set to revolutionize the drying process, making it even more reliable and eco-friendly.

FAQs About Flash Dryers

- What is a flash dryer used for?

Flash dryers are used to remove moisture from a wide range of materials, such as powders, granules, and heat-sensitive products, in industries like food processing, pharmaceuticals, chemicals, and minerals. - How does a flash dryer work?

A flash dryer uses a high-velocity stream of hot air to instantly dry materials by suspending them in the air stream. This rapid process minimizes exposure to heat while ensuring efficient moisture removal. - What materials can be dried using a flash dryer?

Flash dryers can handle a variety of materials, including starch, spices, pharmaceutical powders, chemicals, minerals like kaolin, and more, provided the material has the appropriate size and moisture content. - What are the advantages of a flash dryer over other drying methods?

Flash dryers are faster, more energy-efficient, and require less floor space than traditional drying methods like rotary or spray dryers. They also minimize thermal degradation of heat-sensitive materials. - What factors should I consider when selecting a flash dryer?

Key factors include the material’s moisture content, heat sensitivity, particle size, throughput requirements, energy source availability, and the space available in your facility. - Is a flash dryer suitable for heat-sensitive materials?

Yes, flash dryers are ideal for heat-sensitive materials because they use a very short drying time, minimizing thermal degradation and preserving product quality. - What is the energy consumption of a flash dryer?

The energy consumption of a flash dryer varies depending on the material, drying temperature, and throughput. However, they are designed to be energy-efficient, making them cost-effective for industrial use. - What maintenance is required for a flash dryer?

Regular cleaning, inspection of air filters and fans, monitoring air temperature, and replacing worn-out components like gaskets and seals are essential for optimal performance. - How long does it take to dry materials in a flash dryer?

Drying time in a flash dryer is typically a matter of seconds, depending on the material properties, air temperature, and airflow velocity. - Can a flash dryer handle high moisture content materials?

Flash dryers can handle materials with moderate to high moisture content, but pre-drying or dewatering may be required for materials with very high moisture levels to achieve optimal results.

Conclusion

Flash dryers are an indispensable asset in industrial drying, offering unparalleled speed, efficiency, and adaptability. Whether you’re in food processing, pharmaceuticals, or minerals, investing in a flash dryer can significantly enhance your production capabilities while ensuring cost savings.

Ready to learn more about industrial drying solutions? Explore our extensive resources at EngiTech and stay updated on the latest innovations in drying technology.

Dive deeper into the world of industrial drying and discover tailored solutions for your business. Visit EngiTech for expert advice, in-depth guides, and cutting-edge technologies to optimize your processes today!