Rotary Vacuum Paddle Dryer (RVPD): The Ultimate Guide to Efficient Thermal Drying Technology

Have you ever wondered how pharmaceutical companies efficiently dry temperature-sensitive materials without damaging their properties? Or how chemical manufacturers achieve consistent drying results for high-value products under controlled conditions? The answer often lies in specialized thermal drying technology—specifically, the Rotary Vacuum Paddle Dryer (RVPD). This remarkable piece of engineering has revolutionized drying processes across multiple industries, offering unparalleled efficiency and product quality compared to conventional drying methods.

In this comprehensive guide, we’ll explore everything you need to know about Rotary Vacuum Paddle Dryers—from their fundamental operating principles to advanced applications across various industries. Whether you’re a process engineer evaluating drying technologies, a facility manager looking to optimize existing operations, or a student studying chemical engineering processes, this in-depth analysis of RVPD technology will provide valuable insights into one of the most versatile drying solutions available today.

Table of Contents

What Is a Rotary Vacuum Paddle Dryer?

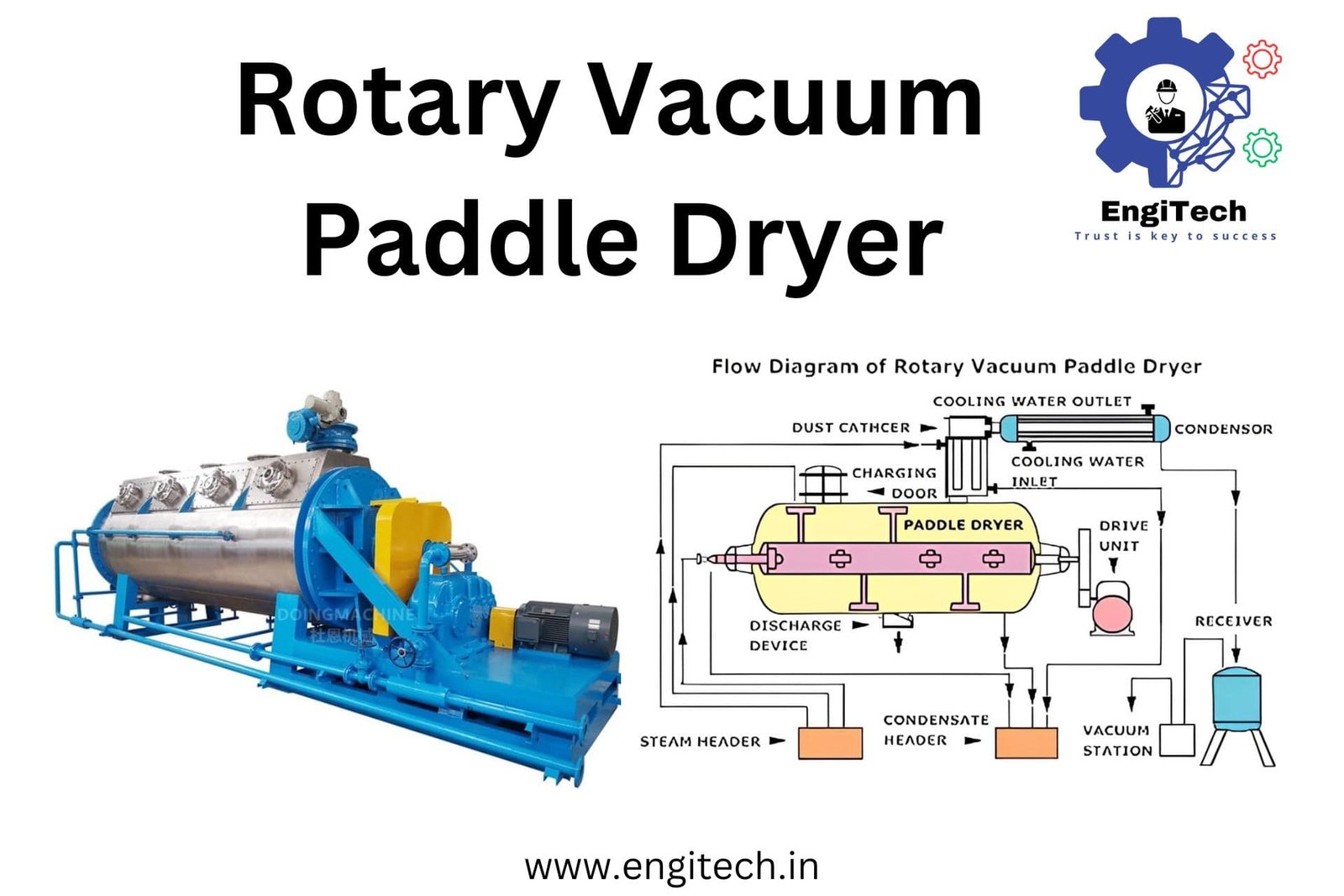

A Rotary Vacuum Paddle Dryer (RVPD) is an advanced indirect heat transfer system designed to efficiently dry wet materials—particularly heat-sensitive, high-value products—under vacuum conditions. Unlike conventional dryers that rely on direct contact with heated air, RVPDs use a jacketed vessel with rotating paddles that simultaneously provides heat transfer and gentle agitation to the material being dried.

Key Components of an RVPD System

The fundamental design of an RVPD includes several crucial components that work together to create an efficient drying environment:

Vapor Recovery System: Equipment that captures and processes the evaporated solvents, either for recovery or safe disposal.

Jacketed Vessel: A horizontally mounted, cylindrical chamber with a heating jacket that circulates thermal fluid (steam, hot water, or thermal oil) to provide indirect heating.

Paddle Assembly: A shaft-mounted system of specially designed paddles that rotate within the vessel, providing continuous material agitation and enhanced heat transfer.

Vacuum System: Pumps and condensers that create and maintain low-pressure conditions within the vessel, significantly lowering the boiling point of solvents and moisture.

Drive and Control Systems: Motors, gearboxes, and sophisticated control systems that regulate rotation speed, temperature, vacuum levels, and process duration.

How RVPDs Work: The Science Behind the Technology

The operating principle of an RVPD combines several physical processes to achieve efficient drying:

Heat Transfer Mechanism: Heat is transferred from the thermal fluid in the jacket through the vessel wall and paddles to the product being dried. This indirect heating approach prevents direct exposure to high temperatures, making it ideal for heat-sensitive materials.

Agitation and Mixing: The rotating paddles create gentle but thorough agitation of the material, ensuring uniform heat distribution and preventing hot spots or localized overheating.

Vacuum Operation: By operating under vacuum (typically 5-100 mbar absolute pressure), the equipment substantially lowers the boiling point of water and solvents. This allows for effective moisture removal at much lower temperatures than atmospheric drying methods would require.

Continuous Surface Renewal: The paddle design continuously exposes fresh material surfaces to the heated vessel walls, maximizing evaporation efficiency and minimizing drying time.

Advantages of Rotary Vacuum Paddle Dryers

RVPDs offer numerous advantages over alternative drying technologies, particularly for specialized applications where product quality and process control are paramount:

Low-Temperature Processing

One of the most significant benefits of RVPDs is their ability to operate at reduced temperatures while maintaining efficient drying performance. This feature is particularly valuable for:

- Heat-sensitive pharmaceuticals and APIs (Active Pharmaceutical Ingredients)

- Temperature-responsive polymers and specialty chemicals

- Materials prone to degradation, discoloration, or chemical changes at elevated temperatures

For example, a material that might require drying at 120°C under atmospheric conditions could potentially be dried at just 60-70°C under vacuum, preserving its critical properties and characteristics.

Superior Product Quality

The gentle processing conditions of RVPDs deliver exceptional product quality advantages:

- Minimized Thermal Degradation: Lower processing temperatures reduce the risk of chemical degradation, preserving active ingredients and sensitive compounds.

- Controlled Particle Size Distribution: The gentle agitation helps maintain particle integrity, preventing excessive breakage or agglomeration.

- Enhanced Purity: Vacuum operation reduces oxidation risk and prevents contamination from airborne particles.

- Consistent Moisture Content: The uniform heat distribution and controlled processing environment result in highly consistent final moisture levels from batch to batch.

Process Efficiency and Flexibility

RVPDs offer significant operational advantages that improve overall manufacturing efficiency:

- Reduced Cycle Times: The combination of efficient heat transfer and vacuum operation often reduces drying times by 30-50% compared to conventional atmospheric dryers.

- Solvent Recovery: The closed system design allows for efficient collection and recovery of valuable solvents.

- Adaptable Processing Parameters: Operators can precisely control temperature profiles, vacuum levels, and agitation intensity to optimize processing for specific materials.

- Scalability: The technology scales effectively from laboratory units (5-10L) to production-scale systems (10,000L+).

Safety and Environmental Benefits

Modern manufacturing facilities increasingly value the safety and environmental advantages that RVPDs provide:

- Contained Processing: The closed system minimizes operator exposure to hazardous materials and reduces environmental emissions.

- Reduced Explosion Risks: Vacuum operation and inert gas capabilities significantly reduce risks associated with flammable solvents.

- Lower Energy Consumption: Reduced processing temperatures and efficient heat transfer result in energy savings compared to direct heating methods.

- Smaller Footprint: The compact design often requires less floor space than alternative technologies with similar capacity.

Applications of Rotary Vacuum Paddle Dryers Across Industries

The versatility of RVPD technology has led to its adoption across numerous industries, each leveraging its unique capabilities to address specific processing challenges:

Pharmaceutical and Biotech Applications

In the pharmaceutical industry, where product integrity and regulatory compliance are paramount, RVPDs have become critical processing equipment:

API Drying: Active Pharmaceutical Ingredients often require gentle drying to preserve molecular structure and activity. RVPDs provide the controlled environment necessary for these high-value materials.

Intermediate Processing: Many pharmaceutical intermediates are heat-sensitive and require precise moisture control. RVPDs deliver the process consistency demanded by strict pharmaceutical manufacturing standards.

Solvent Recovery: The pharmaceutical industry’s focus on sustainability and cost control has made efficient solvent recovery increasingly important. RVPDs excel at capturing and processing valuable solvents for reuse.

Chemical Industry Applications

Chemical manufacturers leverage RVPD technology for various specialized drying applications:

Specialty Chemicals: High-value specialty chemicals often benefit from the gentle processing conditions and precise control offered by RVPDs.

Polymer Processing: Certain polymers and resins require careful drying to achieve specific properties. RVPDs provide the controlled environment necessary for consistent results.

Catalyst Preparation: Catalysts used in various chemical processes often require precise moisture control without compromising activity. RVPDs offer the gentle processing these materials demand.

Food and Nutraceutical Applications

While less common than in pharmaceutical applications, RVPDs are finding increasing usage in specialized food and nutraceutical processing:

Heat-Sensitive Ingredients: Certain food additives, flavors, and nutraceutical compounds benefit from low-temperature vacuum drying to preserve their functional properties.

High-Value Natural Extracts: Botanical extracts and natural compounds often retain better color, flavor, and bioactivity when dried under vacuum conditions.

Enzyme Processing: Enzymes and protein-based ingredients maintain better activity when dried under the gentle conditions provided by RVPDs.

Key Factors in RVPD Selection and Sizing

Selecting the appropriate RVPD for a specific application requires careful consideration of several critical factors:

Material Characteristics

The physical and chemical properties of the material being dried significantly influence RVPD selection:

Moisture Content: Initial and target moisture levels determine processing requirements and cycle times.

Thermal Sensitivity: Materials with low thermal stability require more careful temperature control and may benefit from advanced RVPD designs with enhanced temperature uniformity.

Flowability: Highly cohesive or sticky materials may require specialized paddle designs to prevent material buildup or poor mixing.

Solvent Types: Different solvents have varying vapor pressures and latent heat requirements, affecting vacuum system sizing and condenser design.

Production Requirements

Operational needs also play a crucial role in equipment selection:

Batch Size: Production volume requirements determine the appropriate vessel size and associated utilities.

Cycle Time Requirements: Production scheduling constraints may necessitate faster drying cycles, influencing heat transfer surface area and vacuum system capacity.

Cleaning and Changeover Needs: Facilities processing multiple products must consider ease of cleaning, with options ranging from manual cleaning to fully automated Clean-In-Place (CIP) systems.

Containment Requirements: Handling potent compounds or highly hazardous materials may require specialized containment features such as split butterfly valves or isolator integration.

Facility Constraints

Existing infrastructure often imposes limitations that must be considered:

Available Utilities: The capacity of existing steam, cooling water, and electrical systems can influence equipment selection.

Space Limitations: Floor space and ceiling height constraints may favor more compact RVPD designs.

Explosion Risk Management: Facilities processing flammable solvents must consider appropriate safety systems, including explosion venting or pressure-resistant designs.

Advanced Features and Recent Innovations in RVPD Technology

The evolution of RVPD technology continues to deliver enhanced performance and functionality:

Advanced Heating and Cooling Capabilities

Modern RVPDs often incorporate sophisticated thermal management features:

Dual Thermal Systems: Some advanced units offer both heating and cooling capabilities within the same jacket, allowing for precise temperature control throughout the drying cycle.

Zoned Temperature Control: Segmented jacket designs permit different temperature zones along the vessel length, optimizing heat transfer for challenging materials.

Advanced Heat Transfer Fluids: Specialized thermal fluids allow operation across wider temperature ranges with improved energy efficiency.

Enhanced Process Control

Sophisticated instrumentation and control systems improve process consistency and monitoring:

PAT (Process Analytical Technology) Integration: In-line sensors for moisture content, particle size, and other critical parameters enable real-time process monitoring and control.

Automated Recipe Management: Computerized control systems can store and execute complex drying protocols with minimal operator intervention.

Data Logging and Analysis: Advanced systems capture comprehensive process data for quality assurance, troubleshooting, and continuous improvement.

Mechanical Innovations

Continuous refinement of mechanical components improves performance and reliability:

Optimized Paddle Designs: Computational fluid dynamics and extensive testing have led to paddle configurations that provide more uniform mixing with reduced power consumption.

Seal Technology Improvements: Advanced seal designs reduce maintenance requirements and improve containment for highly potent or hazardous materials.

Wear-Resistant Materials: Specialized alloys and surface treatments extend equipment life when processing abrasive materials.

Operational Best Practices for RVPD Systems

Maximizing the performance and lifespan of RVPD equipment requires adherence to operational best practices:

Process Optimization Strategies

Fine-tuning operational parameters can significantly improve RVPD performance:

Temperature Profiling: Rather than maintaining constant temperature throughout the drying cycle, many materials benefit from programmed temperature ramps that adapt to changing material properties during drying.

Vacuum Sequencing: Strategic adjustment of vacuum levels during different drying phases can optimize solvent removal while preventing issues like excessive foaming or material entrainment.

Agitation Speed Control: Varying paddle rotation speeds during different drying phases can enhance heat transfer while minimizing mechanical stress on the product.

Maintenance and Reliability Considerations

Proactive maintenance ensures consistent performance and extended equipment life:

Seal Inspection and Replacement: Regular inspection and maintenance of shaft seals prevent vacuum leaks and potential contamination.

Heating System Maintenance: Proper treatment of thermal fluids and regular inspection of heating surfaces prevent efficiency losses and potential downtime.

Mechanical Drive Components: Scheduled lubrication and inspection of gearboxes, bearings, and drive components prevent unexpected failures.

Cleaning Validation and Changeover Procedures

For facilities processing multiple products, effective cleaning is essential:

Cleaning Protocol Development: Establish validated cleaning procedures appropriate for the specific materials being processed and the required level of cleanliness.

Design for Cleanability: Features such as polished surfaces, minimal dead spaces, and accessibility for inspection facilitate effective cleaning.

Changeover Documentation: Comprehensive records of cleaning procedures and verification testing support regulatory compliance and quality assurance.

Cost Considerations and ROI Analysis for RVPD Implementation

Investing in RVPD technology requires careful financial analysis:

Capital Investment Factors

The initial investment in RVPD technology includes several components:

Equipment Cost: Base equipment costs vary significantly depending on size, materials of construction, and included features.

Installation and Validation: Proper installation, commissioning, and validation (particularly for regulated industries) can add 30-50% to base equipment costs.

Facility Modifications: Required utility upgrades or structural modifications should be included in initial cost projections.

Operating Cost Analysis

Ongoing operational expenses also influence the total cost of ownership:

Energy Consumption: While vacuum operation reduces the temperature requirements, the combined energy usage of heating systems, vacuum pumps, and drive motors must be considered.

Maintenance Expenses: Regular maintenance, spare parts, and occasional repairs contribute to lifetime costs.

Labor Requirements: Operator time for loading, unloading, monitoring, and cleaning affects ongoing operational expenses.

Return on Investment Calculation

Several factors contribute to the potential ROI for RVPD implementation:

Yield Improvements: The gentle processing conditions often result in higher product yields due to reduced degradation and loss.

Quality Benefits: Enhanced product quality may command premium pricing or reduce rejection rates.

Cycle Time Reduction: Faster processing increases production capacity without additional equipment.

Solvent Recovery Value: The ability to recover and reuse expensive solvents can deliver significant ongoing savings.

Common Challenges and Troubleshooting for RVPD Operation

Even well-designed RVPD systems can encounter operational challenges:

Heat Transfer Issues

Inadequate or uneven heating can compromise drying performance:

Scale Formation: Mineral deposits on heat transfer surfaces reduce thermal efficiency and require periodic cleaning.

Inadequate Agitation: Insufficient mixing can result in uneven temperature distribution and “dead zones” within the product.

Thermal Fluid Degradation: Over time, thermal fluids can break down, reducing heat transfer efficiency and potentially causing system damage.

Material Handling Difficulties

Some materials present specific processing challenges:

Wall Adhesion: Sticky materials may adhere to vessel walls, reducing heat transfer and causing uneven drying.

Lumping and Agglomeration: Certain materials tend to form lumps during drying, requiring specialized paddle designs or processing techniques.

Foaming: Some formulations generate foam under vacuum conditions, potentially causing material carryover into the vacuum system.

Process Control Complications

Maintaining optimal processing conditions can be challenging:

Vacuum Fluctuations: Leaks, condensation, or vapor bursts can cause pressure variations that affect drying performance.

End-Point Determination: Accurately identifying when the desired moisture content has been achieved can be difficult without appropriate sensing technology.

Batch-to-Batch Variability: Variations in feed material properties can require adjustments to processing parameters to maintain consistent results.

Future Trends in RVPD Technology

The evolution of RVPD technology continues, driven by industry demands and technological advancements:

Digitalization and Industry 4.0 Integration

The future of RVPD operation will likely incorporate advanced digital capabilities:

Digital Twins: Virtual models that simulate and predict dryer performance will enable proactive optimization and troubleshooting.

AI-Enhanced Control: Machine learning algorithms will increasingly analyze process data to suggest parameter adjustments for optimal performance.

Predictive Maintenance: Advanced monitoring will detect potential issues before they cause production disruptions.

Sustainability Improvements

Environmental considerations are driving several developments:

Energy Efficiency Enhancements: Improved insulation, heat recovery systems, and more efficient drive mechanisms will reduce energy consumption.

Water Conservation: Advanced condenser designs will minimize cooling water requirements.

Carbon Footprint Reduction: Integration with renewable energy sources and overall efficiency improvements will reduce environmental impact.

Expanded Application Areas

Ongoing innovation will continue to expand the range of suitable applications:

Continuous Processing: While traditionally batch-oriented, hybrid continuous-vacuum drying systems are emerging for certain applications.

New Material Types: Ongoing research is expanding the range of materials that can be effectively processed in RVPDs, including highly viscous compositions and challenging biological materials.

Miniaturization: Smaller, more efficient laboratory-scale units are making RVPD technology accessible for research and development applications.

Case Studies: RVPD Success Stories

Pharmaceutical Manufacturing Transformation

A leading pharmaceutical manufacturer struggling with inconsistent moisture content in a temperature-sensitive API implemented an RVPD system with advanced process controls. The results were remarkable:

- 40% reduction in drying time

- 99.8% solvent recovery (compared to 65% with previous technology)

- Elimination of product degradation issues that had previously affected 5-8% of batches

- ROI achieved in less than 18 months through combined savings and quality improvements

Specialty Chemical Production Optimization

A specialty chemical producer replaced an aging tray dryer with a modern RVPD system for their high-value catalyst materials:

- Reduced drying temperature from 110°C to 65°C

- Improved product activity by 15%

- Decreased batch-to-batch variation in moisture content from ±2% to ±0.3%

- Reduced operator exposure to hazardous materials through contained processing

Food Ingredient Processing Innovation

A natural ingredient manufacturer implemented RVPD technology for drying heat-sensitive fruit extracts:

- Preserved 95% of key bioactive compounds (compared to 70% with conventional drying)

- Improved color retention and flavor profile

- Reduced energy consumption by 35% compared to previous spray drying process

- Enhanced product differentiability and market positioning as a premium ingredient

Conclusion

Rotary Vacuum Paddle Dryers represent a pinnacle of thermal drying technology, offering unparalleled precision, efficiency, and product quality benefits. While the initial investment may exceed that of conventional drying systems, the combined advantages of reduced processing times, improved product quality, enhanced solvent recovery, and operational flexibility deliver compelling long-term value for manufacturers across multiple industries.

As processing demands continue to evolve—with increasing emphasis on product quality, efficiency, and sustainability—RVPD technology will remain at the forefront of advanced drying solutions. Organizations seeking to optimize their drying processes would do well to evaluate whether this sophisticated technology aligns with their specific material characteristics, production requirements, and quality objectives.

Whether you’re considering implementing your first RVPD system or looking to optimize existing equipment, the fundamental principles and best practices outlined in this guide provide a solid foundation for success with this versatile and powerful drying technology.

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.