Waste Water Treatment Plant: Complete Guide to Process, Types, and Benefits

In 2024, the United Nations reported that nearly 44% of all domestic and industrial wastewater worldwide is discharged without adequate treatment. That’s billions of liters of toxic, chemical-laden water flowing into rivers, lakes, and oceans—daily.

Yet this global issue has a local solution.

Whether you’re managing an industrial plant, a residential township, or a commercial complex, the answer lies in a robust waste water treatment plant. These engineered systems not only clean and reuse water—they safeguard public health, protect ecosystems, and ensure long-term sustainability.

In this guide, we’ll break down everything you need to know about a waste water treatment plant (WWTP), including:

- How it works

- The types (STP, ETP, ZLD, CETP)

- Treatment process steps

- Key components

- Benefits, compliance needs, and real-world applications

Let’s start with the basics: what exactly is a waste water treatment plant, and why does every facility—industrial or domestic—need one?

Table of Contents

What Is a Waste Water Treatment Plant?

A waste water treatment plant (WWTP) is a facility designed to remove contaminants from water discharged from households, industries, or commercial facilities, making it safe for discharge or reuse.

In simple terms, it’s where dirty water becomes usable again.

What Does It Treat?

Waste water can come from:

- Homes and buildings (toilets, kitchens, laundry—called sewage or domestic wastewater)

- Factories and processing units (chemical-rich effluent or industrial wastewater)

- Stormwater runoff and greywater systems

Each source carries different pollutants—solids, grease, pathogens, heavy metals, chemicals, or microplastics. A WWTP is designed to treat these specific loads.

Main Objectives of a WWTP:

- Protect natural water bodies from pollution

- Remove harmful substances (BOD, COD, oil, solids, pathogens)

- Comply with discharge regulations set by CPCB, SPCBs, or EPA

- Facilitate water reuse in gardening, flushing, process water, cooling towers, etc.

- Recover resources like energy (from sludge) or treated water for industrial use

Types of WWTPs Based on Application:

| Type | Description |

|---|---|

| Sewage Treatment Plant (STP) | Treats domestic sewage from buildings, townships, offices |

| Effluent Treatment Plant (ETP) | Treats industrial wastewater containing chemical, organic, or toxic pollutants |

| Combined Effluent Treatment Plant (CETP) | Central plant for industrial clusters or industrial zones |

| Zero Liquid Discharge (ZLD) | Advanced system ensuring no liquid is discharged—ideal for water-scarce and compliance-driven industries |

Compliance and Regulatory Bodies:

- In India, WWTPs must follow the CPCB/SPCB norms under the Environment Protection Act, 1986

- In the United States, treatment is governed by the EPA’s Clean Water Act

- Globally, wastewater plants help meet the UN Sustainable Development Goals (SDG 6: Clean Water & Sanitation)

ChatGPT said:

Excellent. Here’s the next section of your blog on Waste Water Treatment Plant, covering the major types of treatment plants in detail. This section is written to educate buyers, engineers, sustainability managers, and decision-makers about choosing the right system for their needs.

Types of Waste Water Treatment Plants

Wastewater isn’t one-size-fits-all. The type of contaminants—and the required level of treatment—can vary widely depending on whether the water comes from a residential apartment, a textile factory, or a food processing plant.

That’s why there are several different types of wastewater treatment systems, each designed for a specific purpose. Let’s look at the most common ones.

1. Sewage Treatment Plant (STP)

An STP is designed to treat domestic sewage—that is, water coming from:

- Toilets and bathrooms

- Kitchens and wash areas

- Laundry and handwashing stations

You’ll typically find STPs in:

- Residential societies

- Hotels and resorts

- Commercial office buildings

- Hospitals and educational campuses

Key Features:

- Uses biological treatment to remove organic matter

- Often includes aeration tanks and clarifiers

- Final treated water is used for flushing, gardening, or HVAC cooling

Regulations:

STPs must comply with local discharge norms (e.g., BOD < 10 mg/L in many cities). In India, real estate developers are required to install STPs in projects above a certain built-up area.

2. Effluent Treatment Plant (ETP)

An ETP is designed for industrial wastewater, which is often far more complex than domestic sewage. Effluent may contain:

- Chemicals

- Oils and greases

- Suspended solids

- Toxins or heavy metals

Industries that require ETPs include:

- Textiles

- Pharmaceuticals

- Chemicals

- Petrochemicals

- Food & beverage processing

- Metal finishing and electroplating

Key Features:

- Uses physical, chemical, and biological processes

- Custom-designed based on industry and effluent profile

- May include neutralization, flocculation, dissolved air flotation (DAF), and advanced oxidation

Goal: To meet local pollution control board limits before water is discharged or reused.

3. Common Effluent Treatment Plant (CETP)

A CETP serves a group of industries—usually in an industrial cluster or estate—that individually can’t afford or manage their own treatment systems.

Example: A textile park with 80 small dyeing units may have a CETP that collects and treats all their effluent together.

Key Features:

- Centralized management

- Shared capital and operational costs

- Often supported or regulated by government agencies

- Includes monitoring systems to ensure each unit complies with inlet standards

Limitations:

Inlet quality varies. Pre-treatment at each unit is often required to avoid process upset.

4. Zero Liquid Discharge (ZLD) Systems

A ZLD system ensures no liquid waste leaves the facility. Every drop of wastewater is:

- Treated

- Recovered

- Reused

- Or evaporated into a solid for landfill

These systems are essential for:

- Highly polluting industries

- Locations with water scarcity

- Companies aiming for water positivity or ESG goals

Typical ZLD Setup:

- Primary and secondary treatment

- Ultra-filtration (UF)

- Reverse Osmosis (RO)

- Multiple Effect Evaporator (MEE)

- Agitated thin film dryer or paddle dryer for salt/sludge management

Challenges:

High CapEx and OpEx, but long-term environmental and compliance benefits.

Quick Comparison: Types of WWTPs

| Type | Treats | Used By | Discharge | Cost | Complexity |

|---|---|---|---|---|---|

| STP | Domestic sewage | Residential, commercial, hospitality | Usually reused or discharged | Medium | Moderate |

| ETP | Industrial effluent | Factories, processing units | Treated & discharged/reused | High | High |

| CETP | Combined industrial waste | Small units in clusters | Centralized | Shared | Moderate |

| ZLD | All wastewater | ESG-conscious, high-load industries | No discharge | Very High | Very High |

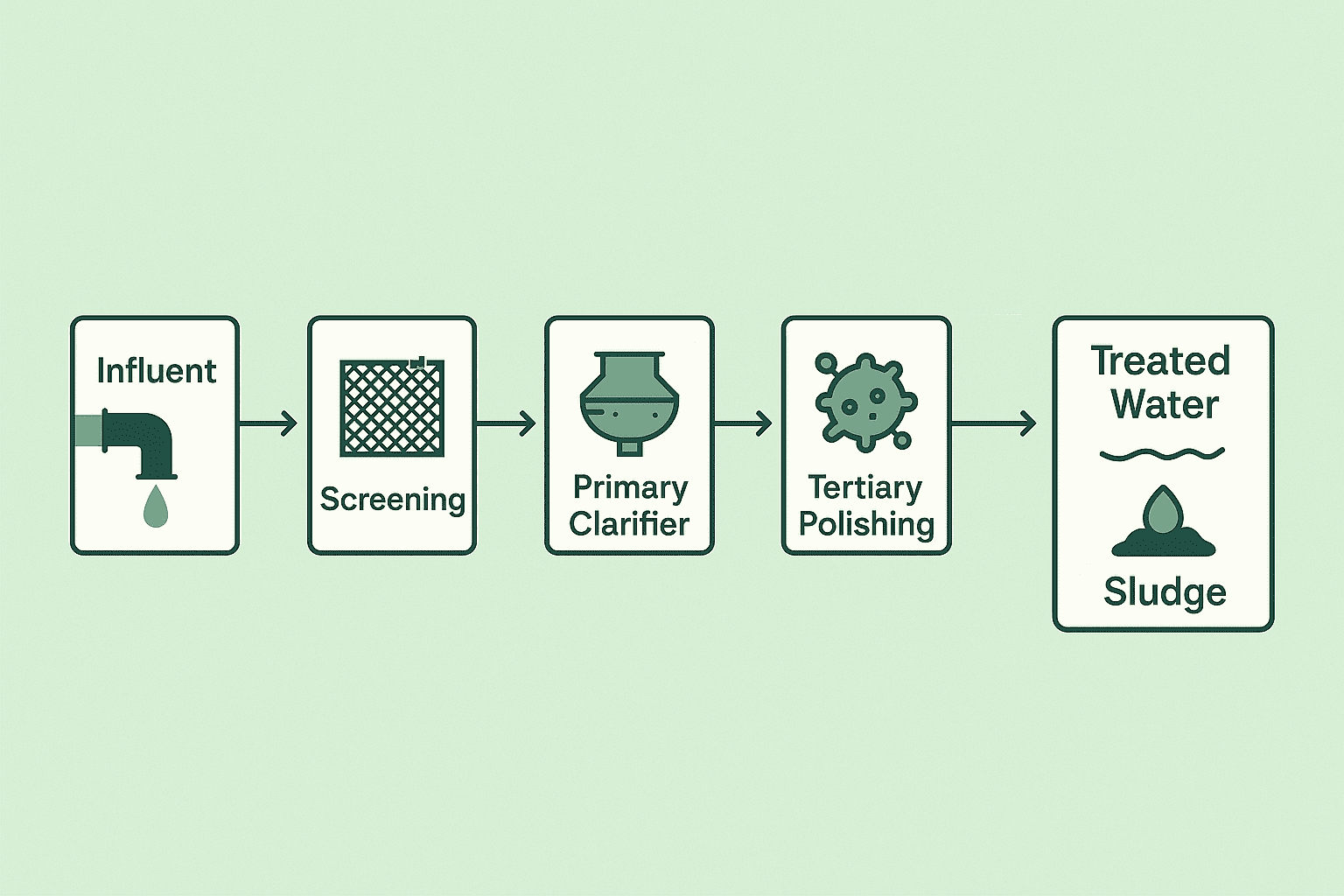

Step-by-Step Waste Water Treatment Process

A waste water treatment plant doesn’t just “clean” water. It systematically removes solids, chemicals, and pathogens through a multi-stage process that combines physical, biological, and chemical treatment.

Let’s break it down into five key stages:

1. Preliminary Treatment

Purpose: Remove large, solid particles that can damage equipment or clog later processes.

Key Steps:

- Screening: Removes floating matter like plastic bags, rags, twigs, and other debris using bar screens or mechanical screens.

- Grit Removal: Settles heavier particles like sand, stones, or gravel in grit chambers.

- Oil and Grease Trap: Separates oils and fats that float on water, typically in residential or food-processing STPs.

End Result: Protects pumps, pipelines, and aeration systems downstream.

2. Primary Treatment

Purpose: Settle out suspended solids and reduce the organic load before biological treatment begins.

Key Steps:

- Primary Clarifier (Settling Tank): Water is held in large tanks where heavy solids settle at the bottom (forming primary sludge) and floating material is skimmed off.

- Retention Time: Usually 2–3 hours for effective sedimentation.

End Result: Removes about 30–50% of BOD (Biochemical Oxygen Demand) and TSS (Total Suspended Solids).

3. Secondary (Biological) Treatment

Purpose: Biologically degrade the dissolved and suspended organic matter using microbes.

Common Biological Treatment Technologies:

- Activated Sludge Process (ASP): Uses aeration tanks to feed oxygen to bacteria that break down organic pollutants. Followed by a secondary clarifier to settle biomass.

- Moving Bed Biofilm Reactor (MBBR): Biofilm-coated plastic media enhances microbial growth.

- Sequential Batch Reactor (SBR): Time-based batch process with aeration and settling cycles.

- Submerged Aerated Filter (SAF): Compact aerobic system using structured media and air diffusers.

End Result: Reduces BOD and COD levels significantly (>90%), and lowers pathogen concentration.

4. Tertiary Treatment

Purpose: Polish treated water to make it suitable for reuse or environmentally safe discharge.

Technologies Used:

- Sand/Carbon Filtration: Removes turbidity, color, and residual organics.

- Ultra-Filtration (UF): Removes fine particles and bacteria.

- Reverse Osmosis (RO): Used in ZLD systems to recover high-purity water.

- UV or Chlorine Disinfection: Destroys remaining pathogens.

End Result: Achieves final treated water quality fit for:

- Flushing

- Cooling tower makeup

- Gardening/landscaping

- Boiler feed water (after RO)

5. Sludge Handling and Disposal

Wastewater treatment generates solid sludge, which must be processed and disposed of safely.

Common Sludge Handling Steps:

- Sludge Thickening: Uses gravity or flotation to reduce water content.

- Sludge Dewatering: Uses filter presses, decanter centrifuges, or paddle dryers to reduce moisture to 15–25%.

- Disposal or Reuse:

- Sent to authorized landfills or TSDF

- Reused as fuel (if calorific value is high)

- Used in composting (if biodegradable and non-toxic)

End Result: Safe, reduced-volume sludge ready for disposal or valorization.

Key Components of a Waste Water Treatment Plant

Every waste water treatment plant—whether an STP for a residential complex or a ZLD plant for an industrial unit—consists of integrated components that perform specific functions. When correctly sized and installed, these components ensure smooth treatment, reduced downtime, and regulatory compliance.

Here’s a walkthrough of the essential units:

1. Bar Screen Chamber

- Function: Removes large floating solids like plastics, leaves, and cloth

- Types: Manual bar screens, mechanical bar screens

- Location: First point of contact for incoming raw sewage or effluent

Why It Matters: Protects downstream equipment from clogging or damage.

2. Oil & Grease Trap

- Function: Captures floating oils, fats, and grease (especially in kitchens, food units, and workshops)

- Design: Often a compartmentalized chamber that slows water velocity and lets oils rise to the surface

Why It Matters: Prevents oil from forming scum in aeration tanks or clogging filters.

3. Equalization Tank (Optional but Common)

- Function: Balances flow and pollutant concentration before biological treatment

- Features: Agitation systems and air blowers to prevent settling and odor

Why It Matters: Stabilizes loading on biological treatment, especially in batch-discharge industries.

4. Primary Clarifier (Settling Tank)

- Function: Allows suspended solids to settle through gravity

- Output: Primary sludge (sent for dewatering), clarified water (sent for aeration)

Why It Matters: Reduces organic and solids load entering secondary treatment.

5. Aeration Tank / Biological Reactor

- Function: Hosts microbial activity to biologically degrade organic matter

- Types:

- Conventional Activated Sludge

- MBBR (Moving Bed Biofilm Reactor)

- SAFF (Submerged Aerated Fixed Film)

- SBR (Sequential Batch Reactor)

Why It Matters: This is the heart of the biological treatment stage.

6. Secondary Clarifier (Settling of Biomass)

- Function: Settles biological flocs and returns some of the sludge to maintain microbial population

- Output: Treated water moves to filtration; sludge moves to dewatering

Why It Matters: Ensures clear effluent post-biological stage.

7. Tertiary Treatment Unit

- Function: Final polishing stage

- Includes:

- Pressure sand filters (PSF)

- Activated carbon filters (ACF)

- UF/RO units (in ZLD setups)

- UV or chlorine dosing

Why It Matters: Prepares water for safe discharge or reuse in utilities like flushing, gardening, or cooling towers.

8. Sludge Handling System

- Function: Processes settled solids from clarifiers

- Equipment Used:

- Sludge thickener

- Filter press

- Paddle dryer (for advanced drying and fuel recovery)

Why It Matters: Without proper sludge treatment, you risk odor, overflow, and compliance violations.

9. Control Panel and Automation System

- Function: Operates pumps, blowers, valves, dosing systems, and sensors

- Modern Add-ons:

- SCADA systems for remote monitoring

- SMS/email alerts for breakdowns or alarms

- Flow/pressure/DO sensors

Why It Matters: Ensures smooth and optimized operation with minimum human error.

Benefits of a Waste Water Treatment Plant

A well-designed and efficiently operated waste water treatment plant does more than just clean dirty water. It’s a long-term investment that delivers environmental, operational, and economic advantages—especially in regions with water scarcity, rising utility costs, or strict environmental regulations.

Here’s how your facility stands to benefit:

1. Environmental Protection

A WWTP helps reduce your environmental footprint by:

- Preventing untreated wastewater from polluting rivers, lakes, and soil

- Reducing the spread of waterborne diseases caused by harmful pathogens

- Lowering the chemical and organic load entering ecosystems

- Protecting aquatic life and biodiversity

Bottom line: It’s a frontline defense against water pollution and ecosystem degradation.

2. Regulatory Compliance and Risk Mitigation

Failure to treat wastewater properly can result in:

- Heavy fines from pollution control boards (CPCB, SPCB, EPA)

- Legal actions or license suspensions

- Negative media attention and reputational loss

A functional WWTP helps:

- Maintain permitted discharge standards (BOD, COD, TSS, pH, oil & grease)

- Pass routine inspections and audits

- Avoid business interruptions caused by regulatory actions

3. Water Reuse and Resource Conservation

One of the biggest advantages is the ability to reuse treated water, especially in:

- Flushing toilets

- Cooling towers

- Gardening and landscaping

- Floor washing or HVAC

This reduces your dependence on freshwater sources—critical in urban or drought-prone areas.

Bonus: In ZLD plants, nearly 95–98% of water is recovered and reused internally.

4. Cost Savings in the Long Run

Though installing a WWTP may require upfront capital, it pays off through:

- Reduced water procurement costs

- Lower sewage connection or discharge fees

- Decreased tanker purchase for freshwater

- Less risk of pollution penalties

For industries, especially high-discharge sectors like textiles or food processing, the ROI can be recovered in 2–3 years through water reuse alone.

5. Supports Corporate Social Responsibility (CSR) and ESG Goals

Sustainable wastewater management contributes directly to:

- SDG 6: Clean Water and Sanitation

- ESG metrics under Environmental impact assessments

- Improved ESG ratings for global funding or public listing

- Enhanced brand image with eco-conscious clients or consumers

For certified organizations (like ISO 14001, LEED), a WWTP adds measurable points to environmental scorecards.

6. Sludge Recovery and Energy Savings

Treated sludge, when dried using equipment like paddle dryers, can be:

- Used as fuel in cement kilns or boilers (if calorific value is sufficient)

- Converted into manure (if non-toxic and organic)

- Disposed of at a much lower volume and cost

This turns a liability into a potential asset.

7. Scalability and Flexibility

Modern WWTPs can be:

- Modular – expand capacity as demand grows

- Automated – reduce manpower needs and human error

- Customizable – tailored to industry-specific contaminants

Whether you run a 50 KLD STP for a housing project or a 500 KLD ZLD system for a dyeing plant, WWTPs can be scaled and optimized.

Summary Table: Key Benefits

| Benefit | How It Helps Your Business |

|---|---|

| Environmental Protection | Prevents pollution and ecological damage |

| Legal Compliance | Avoids fines, shutdowns, and permit suspensions |

| Water Reuse | Reduces water bills and supports sustainability |

| Cost Savings | Cuts utility and waste handling expenses |

| CSR/ESG Alignment | Enhances corporate image and investment appeal |

| Sludge Recovery | Generates fuel or reduces waste volume |

| Flexibility | Scales with growth, adaptable to any industry |

Common Challenges and Mistakes in Waste Water Treatment Plant Operation

Even with the right equipment and intentions, many facilities run into problems with their wastewater treatment systems. These issues often arise from design oversights, poor operations, or inconsistent maintenance, leading to compliance failures, breakdowns, or unnecessary operating costs.

Here’s a breakdown of the most common challenges—and how to solve or avoid them.

1. Incorrect Plant Sizing

What Goes Wrong:

Many plants are either overdesigned (wasting money and space) or underdesigned (leading to overflows and poor treatment).

Impact:

- Non-compliance with treated water norms

- Frequent overloads during peak operations

- Inability to accommodate future capacity

Solution:

- Conduct a detailed influent characterization study

- Design for average and peak loads

- Build for scalability (modular designs)

2. Poor Sludge Management

What Goes Wrong:

Sludge builds up in tanks or clarifiers because there’s no clear plan for handling, dewatering, or disposal.

Impact:

- Clogging of pipes and tanks

- Odor issues

- Overflow and poor water quality

Solution:

- Integrate sludge drying systems like filter presses or paddle dryers

- Schedule regular sludge removal

- Maintain proper sludge holding tank capacity

3. Lack of Automation and Monitoring

What Goes Wrong:

Plants operate manually without instruments to measure flow, pH, BOD/COD, or DO levels.

Impact:

- Inconsistent treatment quality

- Operator dependency

- Late detection of problems

Solution:

- Install essential sensors and SCADA/PLC systems

- Use online analyzers for real-time water quality tracking

- Set up SMS/email alerts for critical failures

4. Inadequate Operator Training

What Goes Wrong:

Operators aren’t trained in process flow, emergency handling, or SOPs.

Impact:

- Mishandling of chemicals and equipment

- Safety hazards

- Reduced efficiency and increased wear & tear

Solution:

- Monthly training sessions

- SOPs displayed at every major equipment point

- Emergency drill exercises every quarter

5. Inconsistent Maintenance and AMC Delays

What Goes Wrong:

Pumps, blowers, and filters are neglected until they fail. AMCs are skipped due to budget cuts.

Impact:

- Unplanned breakdowns

- Higher energy consumption

- Poor treatment results

Solution:

- Schedule preventive maintenance

- Sign annual maintenance contracts with OEMs

- Keep basic spares and tools on-site

6. Disregarding Treated Water Quality Testing

What Goes Wrong:

Plants run without regular lab testing or third-party validation.

Impact:

- Violation of CPCB/SPCB standards

- Missed water reuse opportunities

- Risk to health and environment

Solution:

- Test treated water weekly (in-house or via NABL lab)

- Check BOD, COD, TSS, pH, and oil & grease

- Maintain a water quality logbook

7. Neglecting Future Load or Expansion Plans

What Goes Wrong:

Plants are built for current needs without accounting for future capacity increase.

Impact:

- Costly retrofits

- Space constraints

- Regulatory re-approvals required

Solution:

- Design modular units that can be expanded later

- Keep 20–25% space buffer in layout

- Choose technologies with scalability (like MBBR or SBR)

Summary Table: Common Mistakes and Fixes

| Mistake | Impact | Solution |

|---|---|---|

| Under/oversized plant | Inefficient treatment | Right-sizing with future load projections |

| Ignoring sludge management | Odor, overflow | Install drying and dewatering units |

| Manual operations only | Poor accuracy | Add automation and sensors |

| Untrained operators | Mishandling | Regular training and visual SOPs |

| No preventive maintenance | Equipment failure | Scheduled AMCs and spares management |

| Skipping water quality tests | Non-compliance | Weekly lab reports, logbook maintenance |

| No space for expansion | Retrofitting costs | Design modular and future-ready plants |

Case Study: How an Industrial Plant Achieved 90% Water Reuse with a ZLD Waste Water Treatment Plant

Client Background

In 2022, a textile dyeing unit located in Surat, Gujarat, was facing mounting pressure from the State Pollution Control Board (SPCB). The plant processed over 400 KLD of wastewater daily, containing high levels of dyes, TDS, and COD. Discharge into the common CETP was restricted due to non-compliance, and the factory was at risk of suspension.

Key Challenges

- High TDS levels (>7,000 ppm) due to dyeing and chemical processes

- COD above permissible limits despite running a basic ETP

- Limited space for expansion within the industrial estate

- No reuse plan for treated water

- Monthly costs for tanker-supplied freshwater exceeded ₹12 lakhs

The Solution: ZLD-Based Waste Water Treatment Plant

The management decided to invest in a custom-designed Zero Liquid Discharge (ZLD) wastewater treatment system, including:

- MBBR Biological Reactor – for high BOD/COD reduction

- Ultra-Filtration (UF) Unit – to protect the RO membranes

- 2-Stage Reverse Osmosis (RO) System – for maximum water recovery

- Multiple Effect Evaporator (MEE) – for RO reject treatment

- Paddle Dryer – to dry salt sludge into a disposable solid

- Online Monitoring Systems – for pH, flow, and conductivity

Implementation Timeline

| Stage | Time Required |

|---|---|

| Design & Engineering | 3 weeks |

| Civil Foundation & Utilities | 4 weeks |

| Equipment Fabrication | 5 weeks |

| Erection & Commissioning | 3 weeks |

| Total Project Duration | 12–14 weeks |

Results Achieved

| Parameter | Before ZLD | After ZLD Implementation |

|---|---|---|

| Treated Water Reuse | 0% | 90% (used for process and utilities) |

| Monthly Water Tanker Cost | ₹12.2 lakhs | ₹1.5 lakhs (only makeup water) |

| TDS in Final Discharge | 5,800 ppm | <200 ppm (no discharge) |

| SPCB Compliance | Failed inspections | 100% compliance for 18+ months |

| Sludge Volume | 12 tons/month | 2 tons/month (dried cake) |

Lessons Learned

- ZLD is viable even for space-constrained industries with modular layouts

- Paddle dryers significantly reduce sludge volume and cost of disposal

- Long-term water reuse leads to savings, compliance, and sustainability

- A proactive approach to wastewater handling improves regulator relations

This case proves that wastewater is not just a by-product—it’s a recoverable resource. With the right system design, even high-load industrial wastewater can be treated, recycled, and reused efficiently.

Waste Water Treatment Plant vs Sewage Treatment Plant: What’s the Difference?

While the terms WWTP (Waste Water Treatment Plant) and STP (Sewage Treatment Plant) are often used interchangeably, they serve different purposes and treat different types of water. Understanding this distinction is critical when planning infrastructure for residential, commercial, or industrial projects.

Here’s how they differ.

1. Source of Wastewater

- STP (Sewage Treatment Plant):

Treats domestic wastewater—from kitchens, bathrooms, wash basins, and laundry in homes, offices, hotels, and public toilets. - WWTP (Waste Water Treatment Plant or ETP/ZLD):

Treats industrial wastewater, which may include chemicals, oils, heavy metals, dyes, and toxic substances generated from industrial processes.

2. Composition and Contaminants

- STP:

Typically contains organic waste, biodegradable solids, and microbial pathogens. - WWTP:

Can contain non-biodegradable, hazardous, and high-strength pollutants (e.g., acids, solvents, dye waste, oil, and grease).

3. Treatment Process Complexity

- STP:

Generally follows a standard 3-stage process—primary, secondary (biological), and tertiary polishing. - WWTP:

Often requires additional chemical treatment, advanced oxidation, ultra-filtration, or reverse osmosis before water reuse or ZLD compliance.

4. Regulatory Standards

- STP:

Must meet municipal or city-level treated water standards (e.g., BOD < 10 mg/L, TSS < 20 mg/L). - WWTP:

Must comply with state pollution control board (SPCB) or CPCB norms, which vary by industry and may include TDS, heavy metals, and COD restrictions.

5. Design and Infrastructure

- STP:

Compact and standardized, often prefabricated or containerized. - WWTP:

Custom-engineered based on industry type, effluent load, and compliance requirements.

6. Sludge Characteristics

- STP Sludge:

Contains high organic content and may be compostable if stabilized. - WWTP Sludge:

May contain heavy metals or toxic residues, requiring safe drying, solidification, and TSDF-approved disposal.

Comparison Table: WWTP vs STP

| Feature | STP (Sewage Treatment Plant) | WWTP (Waste Water Treatment Plant) |

|---|---|---|

| Water Source | Domestic sewage | Industrial effluent |

| Pollutant Type | Organic matter, pathogens | Chemicals, heavy metals, dyes |

| Treatment Complexity | Moderate (mostly biological) | High (physical, chemical, biological) |

| Regulatory Norms | Local/municipal | CPCB/SPCB industry-specific |

| Design Type | Standardized or packaged | Customized to effluent characteristics |

| Sludge Disposal | Can be composted if stabilized | May need drying and hazardous disposal |

| Reuse Potential | Flushing, gardening, HVAC | Process reuse, cooling towers, ZLD |

How to Choose the Right Waste Water Treatment Plant for Your Needs

Selecting the right waste water treatment plant isn’t just a technical task—it’s a strategic decision that impacts your compliance, water savings, operating costs, and even your facility’s future scalability.

Whether you’re planning for a residential society, a hotel, or a high-discharge industry, here’s a step-by-step guide to help you make the right choice.

1. Identify the Source and Type of Wastewater

Ask yourself:

- Is the wastewater domestic sewage (from toilets, kitchens, bathrooms)? → You need an STP.

- Is it industrial effluent with chemical or biological loads? → You need an ETP or ZLD plant.

- Are you part of an industrial estate? → Consider a CETP model or shared facility.

🔹 Tip: Test your raw wastewater for pH, BOD, COD, TSS, TDS, and oil & grease to determine treatment complexity.

2. Determine Daily Wastewater Volume (Flow Rate)

- Small-scale: < 25 KLD (residential towers, commercial units)

- Medium-scale: 25–250 KLD (schools, hospitals, food outlets, small factories)

- Large-scale: > 250 KLD (industrial plants, large housing societies, malls, airports)

Treatment capacity (in KLD – kiloliters per day) will influence:

- Size of tanks

- Footprint required

- Technology used (ASP, SBR, MBBR, etc.)

3. Understand Discharge vs Reuse Needs

- Will the treated water be discharged into a drain?

- Do you want to reuse it for flushing, gardening, process water, cooling towers?

- Are you legally required to achieve ZLD (Zero Liquid Discharge)?

🔹 Tip: If reuse is your goal, ensure the system includes proper tertiary treatment and disinfection (e.g., UF + UV or RO).

4. Evaluate Area and Civil Layout

- Do you have adequate space for all tanks and processing units?

- Is the layout linear, U-shaped, or vertical (containerized)?

- Can you use underground tanks to save surface area?

Space constraints will help determine:

- Whether you need modular units

- If containerized or MBBR-SAF systems are more viable

5. Check Compliance and Local Regulations

- Refer to local PCB (Pollution Control Board) or municipal norms for treated water parameters

- Obtain necessary Consent to Establish (CTE) and Consent to Operate (CTO)

- In some states or industrial zones, ZLD or water reuse is mandatory

🔹 Tip: A consultant or OEM can help you prepare the documents and apply for clearances.

6. Choose the Right Technology

| Effluent Type | Recommended Technology |

|---|---|

| Domestic sewage | ASP, SBR, MBBR, SAFF |

| High COD/industrial | ETP with chemical + biological systems |

| High TDS industries | ZLD with RO + MEE + Paddle Dryer |

| Small-scale installations | Packaged or containerized STPs |

7. Decide on Automation Level

- Manual Systems: Lower CapEx, more operator-dependent

- Semi-Automated: Sensors with some PLC controls

- Fully Automated: Remote monitoring, SCADA, auto-dosing, alarm systems

🔹 Tip: Automation improves consistency, reduces manpower, and ensures compliance—especially useful for multi-shift operations.

8. Factor in Sludge Handling

Don’t ignore sludge—it’s a by-product that requires management.

- Add filter press or paddle dryer for sludge dewatering

- Partner with a TSDF or certified waste handler

- Check whether sludge can be used as compost, fuel, or must be disposed of as hazardous waste

9. Assess After-Sales Support and AMC

Choose vendors who offer:

- Local service teams

- Annual maintenance contracts (AMC)

- Spare parts availability

- Commissioning and training support

10. Budget Wisely—But Think Long-Term

While STPs or ETPs may seem costly upfront, the return on investment (ROI) through:

- Water reuse savings

- Lower compliance risks

- Sludge valorization

- Green building ratings

… makes it a smart long-term decision.

Summary: Key Selection Factors

| Factor | Why It Matters |

|---|---|

| Wastewater type | Determines STP, ETP, ZLD, or CETP |

| Flow rate (KLD) | Affects plant size and technology |

| Discharge or reuse | Impacts level of filtration and treatment |

| Space availability | Guides layout and modularity |

| Legal norms | Defines minimum performance requirements |

| Technology and automation | Affects cost, manpower, and reliability |

| Sludge plan | Ensures end-to-end treatment |

FAQs About Waste Water Treatment Plants

1. What is a waste water treatment plant?

A waste water treatment plant is a facility that removes contaminants from used water—such as sewage or industrial effluent—so it can be safely reused or discharged into the environment.

2. How does a waste water treatment plant work?

A WWTP works in stages:

- Preliminary treatment removes large solids

- Primary treatment settles suspended particles

- Biological treatment uses microbes to remove organic waste

- Tertiary treatment filters and disinfects the water

- Sludge handling processes leftover solids for safe disposal

3. What is the difference between STP and ETP?

- STP (Sewage Treatment Plant) treats domestic wastewater from homes, offices, and commercial buildings.

- ETP (Effluent Treatment Plant) treats industrial wastewater that may contain chemicals, oils, and toxic substances.

4. What is Zero Liquid Discharge (ZLD)?

ZLD is a treatment approach where all wastewater is treated and reused, with no liquid discharged from the facility. It typically includes RO, evaporators, and dryers to recover maximum water and reduce sludge.

5. Can treated wastewater be reused?

Yes. Treated wastewater can be reused for non-potable purposes like:

- Toilet flushing

- Garden irrigation

- HVAC cooling systems

- Industrial washing and process water

With advanced treatment, it can even be reused in boilers or high-purity applications.

6. How much does a waste water treatment plant cost?

Cost depends on capacity, treatment technology, automation level, and effluent complexity.

- Small STPs (10–50 KLD): ₹5–25 lakh

- Medium ETPs (100–500 KLD): ₹30 lakh–₹1.5 crore

- ZLD systems (500+ KLD): ₹1.5 crore and above

7. Who regulates WWTP standards in India?

In India, the Central Pollution Control Board (CPCB) and respective State Pollution Control Boards (SPCBs) regulate the design, performance, and discharge standards of wastewater treatment plants.

8. What are the key parameters in treated wastewater?

Regulatory norms focus on:

- BOD (Biochemical Oxygen Demand)

- COD (Chemical Oxygen Demand)

- TSS (Total Suspended Solids)

- pH, TDS, and Oil & Grease

Treated water must meet limits set by environmental authorities before reuse or discharge.

Conclusion: Waste Water Treatment Plants Are the Future of Sustainable Operations

From manufacturing plants and textile factories to residential societies and hospitals, waste water treatment plants are no longer optional—they are essential.

They offer more than just compliance. They help:

- Protect natural ecosystems

- Reduce operating costs through water reuse

- Meet sustainability and ESG goals

- Prevent fines, shutdowns, and public backlash

Whether you’re treating domestic sewage or industrial effluent, the key to success is:

- Choosing the right system

- Sizing it correctly

- Maintaining it consistently

- Training your team

- Monitoring results

With growing urbanization, rising water demand, and stricter environmental laws, every drop counts—and every discharge matters.