Vacuum Pack Machine: The Ultimate Guide to Preservation and Cost Savings

Vacuum pack machines have revolutionized the way businesses and households preserve goods. With the rising costs of food and increasing concerns about product safety, vacuum packing technology provides an efficient, reliable solution to keep products fresher for longer while reducing waste. In this in-depth guide, you’ll learn exactly how a vacuum pack machine works, the different types available, industry use cases, and expert tips on maximizing your return on investment.

By the end of this article, you’ll have the knowledge needed to confidently select and use the right vacuum pack machine for your needs—whether you’re a home cook trying to save money on groceries or a business owner striving to improve packaging efficiency.

Table of Contents

Introduction: Why Vacuum Pack Machines Matter

Vacuum packing is an age-old concept where air is removed from a package prior to sealing. This simple yet effective strategy has been used in various industries—foodservice, medical, and industrial manufacturing—to extend product shelf life and reduce the risk of contamination. The surge in popularity of the vacuum pack machine stems from its versatility: one device can package meats, cheeses, liquids, powders, and delicate electronics, all while preserving product integrity.

In recent years, the vacuum pack machine has become indispensable for modern households aiming to stretch their grocery budgets. By removing oxygen from the packaging environment, vacuum sealers keep foods fresh up to five times longer than traditional storage methods. However, individuals aren’t the only ones who benefit: food processing companies, restaurants, and retailers also leverage vacuum packing to meet consumer demands for freshness and quality.

In this comprehensive guide, we’ll dissect the technology behind these machines, explore various types of vacuum sealers, offer expert-backed usage tips, and provide real-world success stories. If you’re wondering how to cut down food waste or deliver high-quality products to customers, keep reading. You’ll walk away with a solid grasp of vacuum pack machine technology, plus actionable steps on how to incorporate this tool into your daily routine or business operations.

How a Vacuum Pack Machine Works

The core principle behind any vacuum pack machine is the creation of a low-pressure environment. Oxygen is the primary driver of spoilage and oxidation in perishable goods. By removing air (especially oxygen) from a package, bacterial growth slows dramatically, helping products last longer. Here’s a simplified breakdown:

- Bag Placement: You place the item you want to seal into a specially designed vacuum bag.

- Air Extraction: The machine extracts nearly all the air from the bag, creating a near-vacuum environment.

- Sealing: Once the air is removed, the machine seals the bag—usually through a heat-sealing strip.

- Cool-Down: The seal cools and solidifies, ensuring the vacuum remains intact.

Many modern vacuum pack machines come with additional features—such as gas flush options, pulse vacuuming, and adjustable sealing times—geared toward preserving delicate items or controlling the residual oxygen level inside the bag. By customizing settings, you can optimize the storage conditions for different products.

Key Benefits of Vacuum Packaging

- Extended Shelf Life: Vacuum-sealed goods resist spoilage longer. For instance, vacuum-packed meat can last up to two or three times longer than non-vacuum-packed equivalents.

- Reduced Waste: When products don’t spoil as quickly, waste decreases. This is especially beneficial for households and businesses facing tight budgets.

- Fresher Taste and Texture: By sealing in natural juices and preventing freezer burn, vacuum packaging preserves taste and texture more effectively.

- Cost Savings: Bulk purchasing becomes feasible because you can portion and store items efficiently without worrying about rapid spoilage.

- Enhanced Product Presentation: Vacuum-sealed products have a professional look that appeals to consumers, boosting perceived value and brand image for commercial ventures.

- Versatile Application: From storing jewelry and documents to prepping sous vide dishes in a professional kitchen, vacuum pack machines suit countless tasks.

These benefits demonstrate why “vacuum pack machine” is a keyword constantly popping up in searches related to food preservation, cost-saving measures, and packaging innovations. The focus on shelf-life extension resonates with both everyday consumers and large-scale industry players.

Types of Vacuum Pack Machines

Vacuum pack machines aren’t one-size-fits-all. Various models exist, each with distinct features and suitability for certain tasks. Here are the three major types:

External Vacuum Sealers

External vacuum sealers are typically smaller and more affordable than their chamber counterparts. They’re designed for lighter use—often found in home kitchens or small-scale operations.

Key Features:

- Clamp-style sealing bar

- Best for solid foods (e.g., fruits, vegetables, meats)

- Lightweight and portable

- Ideal for home use or small catering operations

Pros:

- Lower initial investment

- Simple to operate

- Great for occasional sealing projects

Cons:

- Not ideal for liquids or overly moist foods because the vacuum process can draw liquids into the machine

- Slower sealing times compared to commercial models

Chamber Vacuum Sealers

Chamber vacuum sealers place the entire item inside a chamber. Once the lid closes, the machine removes air from the chamber, not just the bag. This allows for a more efficient, consistent vacuum.

Key Features:

- Internal chamber design

- Can seal both solids and liquids with ease

- Programmable settings for various packaging requirements

- Often used in professional or industrial contexts

Pros:

- Versatile (handles liquids, soups, and marinades)

- Usually offers stronger vacuum pressure

- Less risk of mess or damage to the unit

Cons:

- Higher upfront cost

- Larger footprint, requiring more space

- Might be overkill for casual, infrequent home use

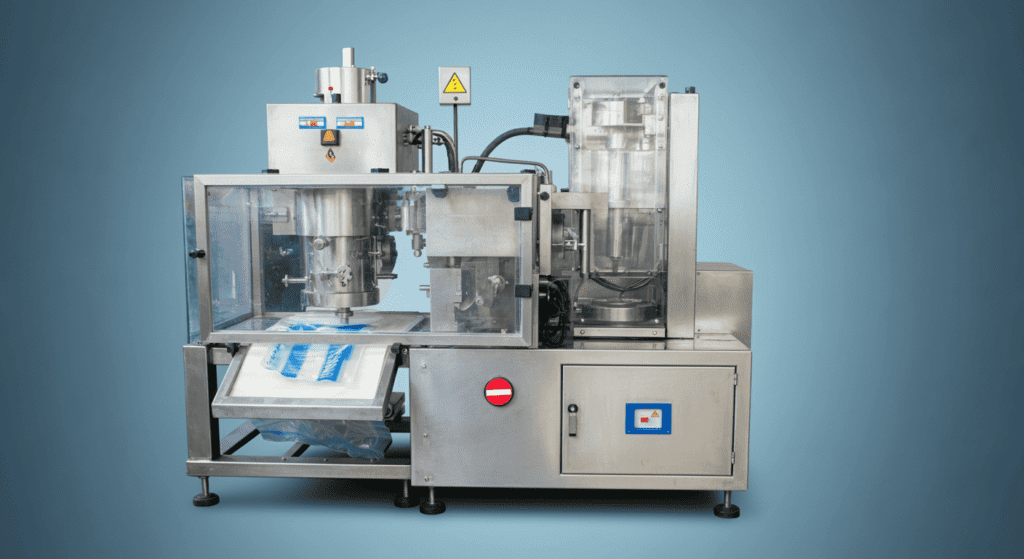

Commercial-Grade Vacuum Sealers

Commercial-grade vacuum sealers take packaging to the next level, often seen in large-scale food processing plants, warehouses, and high-volume restaurants.

Key Features:

- Heavy-duty construction to handle continuous operation

- Customizable vacuum levels, sealing times, and optional gas flush

- Designed for rigorous daily use

Pros:

- Maximizes efficiency in high-output environments

- Extended functionality for specialized needs

- Durable and built to last

Cons:

- Expensive

- Requires professional maintenance

- Not practical for small-scale or home usage unless you have a significant budget and packaging volume

Choosing the Right Vacuum Pack Machine

Selecting the right vacuum pack machine involves balancing your operational needs, budget, and available space. Ask yourself the following questions to narrow your options:

- Volume of Use: How frequently will you use the machine, and how many items will you seal per day or week?

- Product Type: Are you packaging dry goods, liquids, or delicate items like electronics?

- Budget Considerations: Do you have the financial flexibility to invest in a chamber sealer or commercial-grade machine? Or is a basic external unit sufficient?

- Space Constraints: Will the machine be on a small countertop or in a dedicated packaging area with ample space?

- Maintenance and Lifespan: Are you willing to maintain a more complex unit, or do you want a simpler machine requiring minimal upkeep?

By answering these questions, you can quickly determine whether an external or chamber vacuum pack machine is suitable. For large-scale operations, a commercial-grade vacuum sealer might be the only logical option. However, for household needs, an external vacuum sealer is often the perfect fit—both in terms of functionality and cost.

Step-by-Step: How to Use a Vacuum Pack Machine

Using a vacuum pack machine may vary slightly depending on the model, but the general process remains consistent. Below is a step-by-step guide to help you master the art of vacuum sealing:

- Prepare the Item:

- Clean and dry the product if necessary.

- For solids, trim excess fat or remove unnecessary parts.

- For liquids, ensure you’re using a machine that can handle fluids.

- Choose the Right Bag:

- Select a vacuum sealer bag sized appropriately for your product.

- Ensure the bag has the correct thickness and is compatible with your vacuum pack machine.

- Place Item in the Bag:

- Leave at least 2–3 inches of space at the top for sealing.

- Smooth out wrinkles so the seal can form properly.

- Position the Bag in the Machine:

- For external sealers, align the bag opening under the sealing bar.

- For chamber sealers, place the entire bag inside the chamber.

- Activate the Machine:

- Close the lid or clamp bar.

- Press the “Start” or “Vacuum” button.

- The machine will remove air and seal the bag.

- Cool and Inspect:

- Let the seal rest for a few seconds before removing the bag.

- Check the seal’s integrity. A proper seal has no wrinkles or air pockets.

- Label and Store:

- Use a permanent marker or label to note the date and contents.

- Store the vacuum-sealed item in a freezer, refrigerator, or pantry based on storage requirements.

Following these steps ensures that your items remain fresh while minimizing the chances of contamination or air leaks.

Common Applications of Vacuum Pack Machines

1. Food Preservation

- Meat and Fish: Vacuum packing raw meats significantly extends their shelf life.

- Fruits and Vegetables: Store produce to maintain freshness and flavor.

- Dry Goods: Keep grains, legumes, and coffee beans away from air and humidity.

2. Sous Vide Cooking

- Marinating ingredients under a vacuum can infuse flavors more quickly.

- Sous vide cooking relies on vacuum-sealed bags to cook foods evenly at precise temperatures.

3. Retail and Commercial Packaging

- Cheese and Deli Meats: Present a professional appearance while preventing spoilage.

- Snack Foods and Candies: Maintain crispness and flavor.

- Spices and Seasonings: Protect herbs from moisture and prolong potency.

4. Document and Artifact Preservation

- Vacuum sealing can protect valuable documents or collectibles from moisture, dust, and oxidation.

5. Electronic Components

- Electronics are vulnerable to static and moisture damage. Vacuum packing helps keep these components in pristine condition until they are ready for use.

Expert Tips for Maximizing Vacuum Packaging Efficiency

- Avoid Overfilling: Overstuffed bags can compromise the seal. Leave enough headspace for a proper vacuum to form.

- Use Proper Bag Materials: Invest in high-quality bags with multi-layer barriers to ensure durability.

- Pre-Freeze Liquids: If you need to vacuum seal soups or sauces with an external machine, partially freeze them first to avoid spillage.

- Season Inside the Bag: When vacuum packing meats for cooking, season them inside the bag to let flavors infuse deeply.

- Monitor Seal Temperature: Adjust seal time based on bag thickness. Too little time leaves a weak seal, while too much can melt the plastic.

- Clean the Machine Regularly: Residue inside the sealing bar or chamber can affect seal quality.

- Date Your Packages: Always label bags with packing dates and contents for easy organization.

- Experiment with Pulse Vacuuming: Some advanced machines have a “pulse” function, allowing you to remove air in short bursts—ideal for fragile items.

- Rotate Stock: Use older vacuum-sealed items first. Even though shelf life is extended, rotation ensures nothing goes to waste.

These tips come directly from industry experts and seasoned home users who have collectively sealed countless items. Small tweaks in your process can yield massive improvements in product quality and shelf life.

Q&A: Frequently Asked Questions

Q1: How long can vacuum-sealed foods last in the freezer?

A: Generally, vacuum-sealed foods can remain fresh in the freezer for 2–3 years, compared to around 6–12 months for items stored without vacuum sealing. Of course, the exact duration depends on the type of food and consistent freezer temperatures.

Q2: Can I use any plastic bag for vacuum sealing?

A: It’s recommended to use vacuum-sealer-compatible bags. These are typically multi-layered to withstand the vacuum process and prevent punctures, ensuring a tight seal.

Q3: Are vacuum pack machines difficult to clean and maintain?

A: Most machines are user-friendly, with removable drip trays or accessible sealing bars for cleaning. Chamber sealers often have compartments to wipe down, but maintenance is usually straightforward if done regularly.

Q4: Can vacuum sealing remove all bacteria and pathogens?

A: Vacuum sealing removes air, slowing bacterial growth, but it doesn’t sterilize food. Perishable items still require refrigeration or freezing, and proper food safety measures should always be followed.

Q5: Is vacuum packaging environmentally friendly?

A: Vacuum packaging can reduce food waste, which benefits the environment. However, single-use plastic bags are a concern. Many manufacturers now offer recyclable or biodegradable vacuum sealer bags to address this issue.

Common Pitfalls and Troubleshooting

Even the most advanced vacuum pack machine can run into hiccups. Here are common pitfalls and how to address them:

- Incomplete Seal

- Cause: Debris or moisture on the sealing edge.

- Solution: Wipe the bag edge before sealing and ensure the sealing bar is clean.

- Bag Deflation After Sealing

- Cause: A tiny puncture or leak in the bag.

- Solution: Check for sharp edges on the product, use thicker bags, and ensure a proper heat seal.

- Overheating

- Cause: Continuous, heavy usage without breaks.

- Solution: Allow the machine to cool between sealing large batches and follow the manufacturer’s guidelines.

- Inconsistent Vacuum Levels

- Cause: Miscalibration or blockages in the pump.

- Solution: Clean the machine, check for kinks in hoses (if applicable), and consult the manual for vacuum pump maintenance.

- Machine Malfunction or Error Codes

- Cause: Electrical issues, worn parts, or software glitches (for digital models).

- Solution: Contact customer support, especially if troubleshooting steps in the manual don’t resolve the problem.

Being aware of these pitfalls lets you maintain consistent results. If you encounter a persistent issue, consult the manufacturer’s guide or reach out to a professional technician.

Industry Insights and Real-World Examples

- Food Processing Plants: Large-scale operations package bulk quantities of meats, cheeses, and snack foods. By using a commercial-grade vacuum pack machine, these facilities significantly reduce spoilage and meet strict hygiene standards.

- Hospitality and Catering: Restaurants and catering companies rely on vacuum packing to prep ingredients in advance, maintain freshness, and streamline event logistics.

- Home Meal Prep Enthusiasts: Individuals who meal prep for the week find vacuum sealing convenient for portioning meals. Sealed portions stay fresh, making healthy eating easier and less wasteful.

- Marine Industry: Fishermen use vacuum pack machines on boats to seal freshly caught fish, preserving the catch until it reaches shore.

- Electronics Manufacturers: Sensitive components and circuit boards are vacuum-sealed to keep out moisture, extending the product’s lifespan before assembly.

These scenarios highlight the universal appeal of vacuum pack machines and illustrate why so many industries have embraced this technology.

Best Practices for Maintenance and Longevity

Maintaining your vacuum pack machine ensures consistent performance and extends its operational life. Consider the following best practices:

- Clean After Each Use:

- Wipe the sealing bar and remove any food particles or moisture.

- Clean drip trays in external sealers.

- Wipe down chamber interiors in chamber sealers.

- Store Properly:

- Keep the machine in a dry, cool place.

- Avoid exposure to extreme temperatures or direct sunlight.

- Follow Manufacturer Guidelines:

- Each machine has unique requirements for lubrication, seal bar replacement, or pump care. Stick to the recommended schedule.

- If your unit has a filter or cooling fan, clean or replace it as advised.

- Use Quality Bags and Accessories:

- Cheaper bags can cause repeated seal failures or leaks.

- Genuine parts and accessories designed for your brand of vacuum pack machine often perform better and last longer.

- Periodically Check Seals and Gaskets:

- The rubber seals in chamber machines degrade over time.

- Inspect for cracks or wear and replace when needed.

By prioritizing machine upkeep, you’ll save money in the long run, reduce downtime, and consistently produce high-quality seals.

Conclusion

A vacuum pack machine is far more than a kitchen gadget or an industrial accessory—it’s a multifunctional tool that addresses the modern demands for efficient packaging, reduced waste, and heightened food safety. Whether you’re sealing prime cuts of steak for your family, prepping inventory in a bustling restaurant, or preserving sensitive electronics, a vacuum pack machine offers tangible benefits such as extended shelf life, better food quality, and cost savings.

By understanding the various types of machines (external, chamber, and commercial-grade), learning proper sealing techniques, and following best practices for maintenance, you can maximize the device’s potential. The result? Fresher products, happier customers (or family members), and a more efficient workflow overall. In an era where every dollar counts and consumer expectations are constantly rising, vacuum pack machines stand out as a strong solution for businesses and households a like.

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.