The Ultimate Guide to Tag Printing Machines – EngiTech

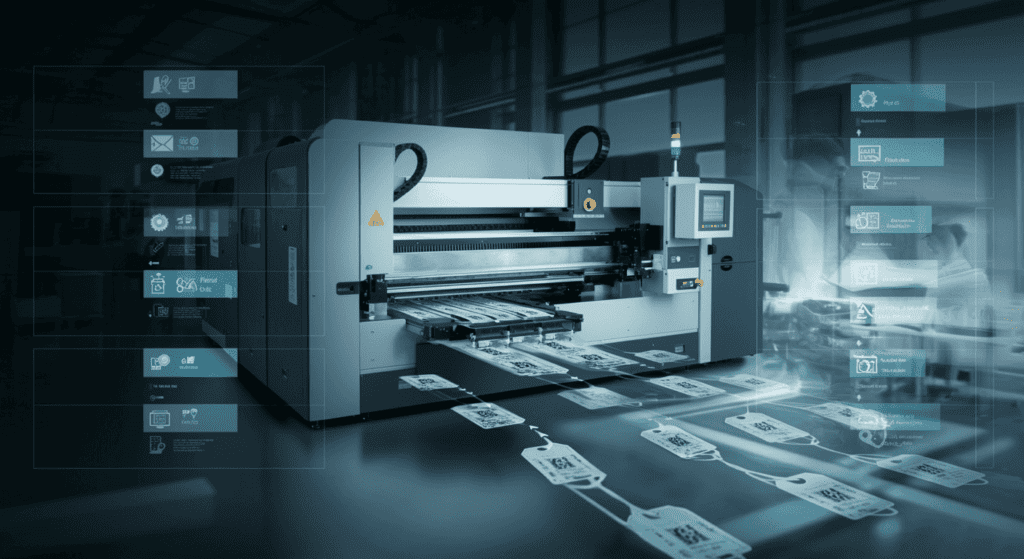

In today’s fast-paced market, the right tag printing machine can revolutionize how businesses handle labeling, branding, and product identification. Whether you run a bustling warehouse, a boutique clothing line, or a multinational manufacturing unit, the efficiency and precision of your tag printing process can make or break operational success.

In this comprehensive guide, we’ll delve into everything you need to know about tag printing machines—from their core functions and industry applications to expert insights on maintenance, troubleshooting, and future innovations.

Table of Contents

Introduction: Why Tag Printing Machines Matter

Imagine you’re fulfilling a massive order on a tight deadline, only to discover that the labels on your products are inaccurate or smudged. This small glitch can lead to big complications—miscommunication in deliveries, confusion among staff, wasted inventory, and unhappy customers. That’s where a tag printing machine steps in as a game-changer.

You’ll learn how to choose the right equipment, integrate it seamlessly into your workflow, and keep it running at peak efficiency. By the end, you’ll be well-equipped with the knowledge to minimize misprints, reduce operational costs, and maintain consistent branding. Let’s dive in.

What Is a Tag Printing Machine?

A tag printing machine is specialized equipment designed to produce tags or labels for various products and industries. These tags can include barcodes, QR codes, brand logos, instructional symbols, RFID data, or simple text. While the earliest forms of tag printing involved manual stamping or mechanical presses, modern technology brings forth high-speed digital and thermal printing solutions that deliver impeccable clarity and durability.

Core Functions

- Precision Printing: Enables accurate reproduction of fonts, symbols, and barcodes.

- Material Compatibility: Works with multiple substrates like paper, synthetic film, fabric, or specialty materials.

- Customization: Allows for variable data printing—like changing serial numbers on the fly.

- Volume Flexibility: Efficiently handles both small and large production runs.

Why Traditional Methods Fall Short

Handwritten or manually stamped tags often result in inconsistent labeling, smudges, and slow production rates. In contrast, an automated tag printing machine ensures faster turnaround and precision—helping you maintain a professional brand image while meeting modern compliance standards (like GS1 for barcodes).

Key Features and Technologies

Tag printing machines have evolved significantly, incorporating cutting-edge technologies that cater to diverse needs. Here are some must-have features to look for when you’re scouting for a machine:

1. Thermal Transfer vs. Direct Thermal

- Thermal Transfer Printing: Uses a ribbon to transfer ink onto a substrate. Ideal for long-lasting tags that can endure extreme conditions like moisture, heat, or abrasion.

- Direct Thermal Printing: Utilizes heat-sensitive paper that darkens when exposed to a thermal printhead. Works great for short-term labels (shipping labels or receipts), but might fade if exposed to sunlight or heat over time.

2. RFID Integration

Radio-frequency identification (RFID) tags help businesses track products through the supply chain. Some tag printing machines come with built-in RFID encoding capabilities, ensuring each label has an embedded chip that can be scanned from a distance without direct line-of-sight.

3. Barcode and QR Code Compatibility

High-resolution printheads make it easy to generate scannable barcodes and QR codes. This is crucial for inventory management, asset tracking, and automated checkout processes.

4. Connectivity Options

- USB/Ethernet: Basic connectivity for desktop setups.

- Wi-Fi/Bluetooth: Wireless printing from multiple devices, enabling more flexible placement on the shop floor.

- Cloud Integration: Allows remote printing and monitoring of tasks for large-scale or multi-site operations.

5. Software and Driver Support

Modern tag printing solutions offer user-friendly software for layout design, database integration, and seamless connectivity with ERP (Enterprise Resource Planning) or WMS (Warehouse Management Systems). Look for software that supports variable data fields, multiple languages, and easy export/import of design templates.

Types of Tag Printing Machines

You’ll find a range of tag printing machines available, each offering a unique blend of speed, resolution, and durability. Understanding these categories can help you select the most suitable model for your needs.

1. Desktop Tag Printers

- Use Case: Ideal for small to medium businesses with moderate printing volumes.

- Advantages: Compact size, easy to operate, budget-friendly.

- Limitations: May struggle with large-scale or continuous printing demands.

2. Industrial Tag Printers

- Use Case: High-volume environments like manufacturing plants, distribution centers, and large warehouses.

- Advantages: Robust design, faster print speeds, can handle bigger label rolls for minimal downtime.

- Limitations: Higher upfront cost and requires more space.

3. Mobile Tag Printers

- Use Case: On-the-go applications such as retail floor price marking, event ticketing, or field service labeling.

- Advantages: Portable, battery-powered, often ruggedized for outdoor or industrial environments.

- Limitations: Limited print volume and features compared to industrial or desktop models.

4. Specialized Textile/Fabric Tag Printers

- Use Case: Printing wash-care labels for garments, or fabric tags for upholstery and mattresses.

- Advantages: Designed for heat-resistant ribbons and durable fabrics.

- Limitations: Niche machines that may have higher operational costs due to specialty consumables.

Industry Applications

A tag printing machine serves countless industries, each with its own specific requirements and regulations:

- Retail & E-commerce

- Common Tags: Price tags, promotional labels, product descriptions, and barcodes.

- Why It Matters: Ensures consistent branding and reliable scannability, especially during peak shopping seasons.

- Manufacturing

- Common Tags: Serial numbers, batch codes, compliance labels, and shipping labels.

- Why It Matters: Streamlines the assembly line, reduces human error, and complies with industry standards like UL or CE.

- Healthcare & Pharmaceuticals

- Common Tags: Patient wristbands, dosage instructions, medication labels.

- Why It Matters: Enhances patient safety, meets regulatory guidelines, and maintains traceability.

- Food & Beverage

- Common Tags: Nutritional info, expiry dates, barcodes, and QR codes for traceability.

- Why It Matters: Complies with health regulations (like FDA requirements) and ensures consumer trust.

- Apparel & Textiles

- Common Tags: Brand labels, size tags, wash-care instructions, RFID for inventory.

- Why It Matters: Sustains brand image, simplifies reordering, and automates stock checks.

- Logistics & Supply Chain

- Common Tags: Shipping labels, pallet tags, asset tracking.

- Why It Matters: Speeds up loading, unloading, and warehouse management, significantly cutting error rates.

Choosing the Right Tag Printing Machine

Selecting the best tag printing machine hinges on analyzing your unique operational needs, budget constraints, and long-term strategic goals. Below are key factors to consider.

1. Printing Volume

Determine how many tags you need to print per day, week, or month. A small retail store might only print hundreds of tags daily, whereas a large warehouse could need tens of thousands.

2. Print Speed and Resolution

- Print Speed: Measured in inches per second (ips). Higher ips is beneficial for fast-paced environments.

- Resolution: Common resolutions range from 203 dpi to 600 dpi or more. For barcodes and logos, 300 dpi is often sufficient, but complex graphics may need 600 dpi.

3. Substrate Compatibility

Not all machines handle the same materials. If you need weather-resistant or heat-resistant tags, verify that your chosen machine supports the necessary ribbons and media.

4. Integration with Existing Systems

Does the printer support your current workflow software or ERP system? Seamless integration can save significant labor hours and reduce data-entry errors.

5. Budget and Total Cost of Ownership (TCO)

Beyond the initial purchase, factor in ongoing expenses like ink ribbons, media, maintenance kits, and potential downtime. A machine that’s cheaper upfront may cost more in the long run if replacement parts are expensive or hard to source.

6. Future-Proofing

If you anticipate business expansion or technological changes (like RFID adoption), invest in a versatile printer that can scale or upgrade accordingly. Spending a bit more now can prevent costly replacements later.

Optimizing Printing Processes and Costs

Once you’ve acquired the right tag printing machine, the next step is to optimize it for maximum efficiency. Below are proven strategies to elevate your printing processes while keeping an eye on your bottom line.

1. Use High-Quality Consumables

Low-grade ribbons or media can lead to smudges, fading, and increased wear on the printhead. Always opt for reputable consumables to ensure longevity and consistent print quality.

2. Maintain Optimal Printhead Pressure

If the printhead pressure is too high, it can wear out the components prematurely. If it’s too low, print quality suffers. Consult your machine’s manual or get professional calibration to strike the right balance.

3. Employ Variable Data Printing

When dealing with products that require unique identifiers—like serial numbers, batch codes, or personalized information—variable data printing can streamline the process by automatically updating the data field for each print job.

4. Implement Preventive Maintenance Schedules

A proactive approach to maintenance ensures fewer breakdowns and consistent performance. Schedule regular check-ups, clean the machine as recommended, and keep track of parts prone to wear and tear.

5. Train Your Staff

Even the most advanced machine can underperform if operators lack the proper training. Invest in instructional sessions that cover everything from loading media to troubleshooting common errors.

Maintenance and Troubleshooting

No machine is infallible, but you can significantly reduce downtime and repair costs with the right maintenance strategy. Let’s break down some essentials.

1. Cleaning the Printhead

Use recommended cleaning swabs or isopropyl alcohol to wipe away residue and dust from the printhead. This not only improves print clarity but also prolongs printhead life.

2. Checking Rollers and Sensors

- Rollers: Over time, debris can accumulate, causing uneven feeding or slippage. Clean or replace rollers as needed.

- Sensors: If sensors are misaligned or covered in dust, they may misread media or fail to detect the start of a new label.

3. Ribbon Wrinkle and Media Jams

Ribbon wrinkles and media jams are common issues that lead to subpar prints or machine damage:

- Ribbon Wrinkles: Ensure the ribbon is tightly wound and properly aligned.

- Media Jams: Regularly inspect the loading path. Use guides or spindles to keep media straight.

4. Common Error Codes

Familiarize yourself with the machine’s error codes—often displayed on an LCD screen or software interface. Typical codes might indicate low ribbon supply, open printhead, or temperature issues.

5. When to Call a Professional

If recurring issues hamper productivity, it may be time to consult authorized service technicians. Persistent error codes or frequent shutdowns can sometimes signal deeper mechanical or electronic malfunctions.

Future Trends in Tag Printing Technology

Technological advancement never stands still, and tag printing machines are no exception. Here’s a glimpse into what the future holds:

1. Eco-Friendly Consumables

With global emphasis on sustainability, manufacturers are developing biodegradable ribbons and recyclable media. Future tag printing machines may also be optimized for lower energy consumption and minimal waste.

2. AI-Driven Quality Control

Artificial intelligence could soon analyze each print in real-time, automatically adjusting settings for optimal print quality. AI can also predict maintenance needs before a breakdown occurs.

3. Enhanced Security Features

Security tags with invisible inks or integrated microchips are on the rise. This deters counterfeiting and boosts traceability for high-value items like electronics, pharmaceuticals, or luxury goods.

4. Cloud-Connected Printing

While some machines already offer cloud integration, expect more advanced features like live monitoring, automated supply ordering, and remote troubleshooting. These advancements reduce operational costs and speed up turnaround times.

5. Scalability and Modular Designs

Future machines may adopt modular systems where you can easily swap out printheads or upgrade to RFID encoding units without replacing the entire printer. This approach could revolutionize how businesses adapt to changing labeling requirements.

FAQs: Your Top Tag Printing Questions Answered

Optimizing for Google’s Featured Snippet often involves structured Q&A. Below are five frequently asked questions about tag printing machines, along with concise, authoritative answers.

- Q: Which industries benefit the most from tag printing machines?

A: Virtually any industry that relies on efficient labeling can benefit—retail, manufacturing, healthcare, food and beverage, and more. The consistent and accurate tagging process improves workflows and ensures compliance with various regulations. - Q: How can I maintain a tag printing machine for the best lifespan?

A: Regular cleaning of the printhead and rollers, using high-quality consumables, and adhering to preventive maintenance schedules are key. Checking for sensor alignment and calibrating pressure levels also helps. - Q: What’s the difference between direct thermal and thermal transfer printing?

A: Direct thermal printing uses heat-sensitive media and is best for short-term labels. Thermal transfer printing uses a ribbon and is ideal for long-lasting tags. Your choice depends on the label’s expected lifespan and environmental conditions. - Q: How do I troubleshoot common ribbon wrinkles or media jams?

A: Ensure the ribbon and media are loaded correctly with proper tension. Regularly clean the rollers, guides, and sensors. If issues persist, refer to your machine’s manual or contact a professional technician.

5. Q:Where can I learn more about advanced tag printing solutions and updates?

A: Stay connected with industry trade shows, manufacturing expos, and reliable online resources. You can also subscribe to product newsletters from reputable brands or follow forums where experts discuss the latest innovations.

- Other References Links :

- GS1 Official Site – For global barcode and supply chain standards.

- OSHA Guidelines on Labeling – Essential for workplace safety compliance.

- Industry Research Reports – Market insights and growth forecasts for labeling equipment.

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.