Sticker Printer Machine: Your Comprehensive Guide to High-Quality, Custom Stickers

Imagine holding a stunning, vibrant sticker in your hand—perfectly printed, crisp lines, and bold colors that draw the eye. Whether you’re a small business owner looking to brand your products or a hobbyist eager to unleash your creativity, a sticker printer machines is the gateway to endless customization.

In this in-depth guide, you’ll learn how to choose the right device, explore various printing materials, understand the intricacies of design, and master best practices to ensure top-notch results. By the time you’re done reading, you’ll know exactly how to turn your ideas into attention-grabbing stickers that resonate with your audience and stand out in any market.

In recent years, the global sticker and label printing industry has seen a surge in demand, fueled by e-commerce, personalized marketing, and the ever-growing popularity of crafting communities. According to research from industry analysts at Grand View Research, the global digital printing packaging market is projected to expand significantly in the coming years—driven in no small part by the rise of small businesses, online sellers, and indie creators who rely on professional-looking labels. If you’re looking to join this revolution—or simply upgrade your capabilities—this guide is your blueprint to selecting and operating a sticker printer machine like a pro.

Table of Contents

1. Understanding the Basics of Sticker Printer Machines

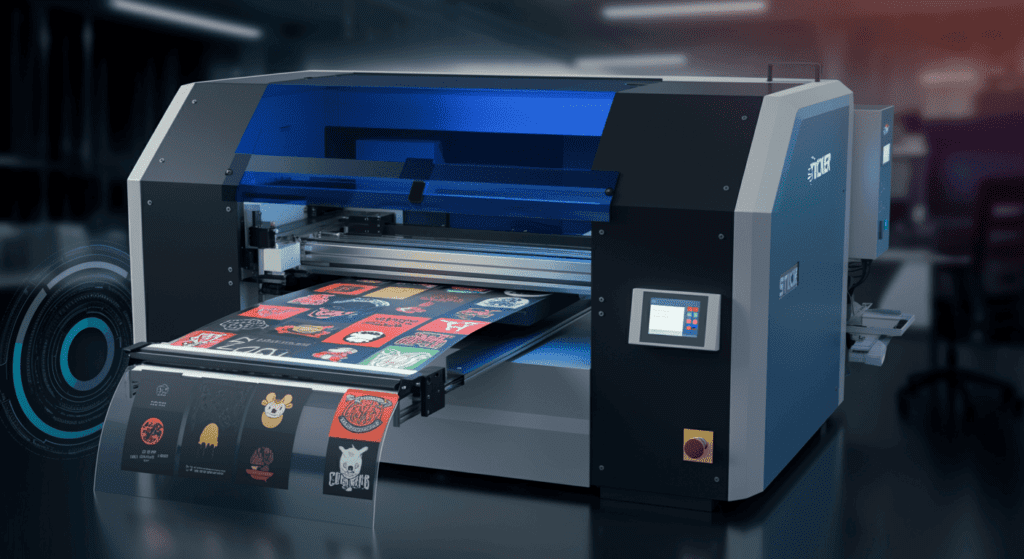

A sticker printer machine is a specialized device designed to print high-quality graphics, text, and images on adhesive materials. Depending on the model, these machines can handle a variety of substrates—including paper, vinyl, polyester, or polypropylene—allowing you to create eye-catching labels, decals, product packaging, window stickers, and more.

Core Components of a Sticker Printer Machine

- Print Head: Delivers ink or toner onto the substrate with exceptional precision.

- Ink/Toner System: Supplies the coloring medium, which can be water-based, solvent-based, UV-curable, or resin-based.

- Media Feed: Guides and holds the substrate in place to ensure precise alignment and consistent printing.

- Control Panel/Software: Allows you to configure settings, such as resolution, speed, and color calibration.

By understanding these components, you’ll be better equipped to compare different printer models and pinpoint the features that are most relevant to your needs.

2. Why Invest in a Sticker Printer Machine?

You might be wondering, “Why not just outsource my printing?” While outsourcing can be a convenient option in certain cases, owning a sticker printer machine offers several advantages that can significantly boost both efficiency and profitability.

- Creative Control: Gain full control over color accuracy, design modifications, and prototype iterations. This is especially beneficial for businesses that frequently experiment with new product labels or marketing materials.

- Quick Turnaround: No more waiting for external print shops. You can produce on-demand labels or stickers, drastically reducing lead times.

- Cost Efficiency: For medium to large volume runs, printing in-house can result in substantial savings. After the initial investment, per-sticker costs often drop dramatically.

- Customization: Cater to unique customer demands—like personalized stickers or limited-edition designs—without having to worry about minimum order quantities.

Whether you’re a small craft-based business or a large-scale manufacturer, investing in a sticker printer machine can pay dividends in brand image, operational agility, and long-term cost savings.

3. Key Features to Look for in a Sticker Printer Machine

Before you jump into buying the first sticker printer machine you spot, take note of key features that define a high-quality device. Your final choice should align with your production goals, budget, and the specific applications you have in mind.

3.1 Print Resolution and DPI

- What It Is: Dots per inch (DPI) measures how many dots of ink or toner a printer can place within a linear inch.

- Why It Matters: A higher DPI yields sharper images, detailed text, and smoother gradients—essential for premium-looking stickers.

3.2 Printing Speed

- What It Is: How fast your printer can output stickers, usually measured in prints per minute or linear inches per second.

- Why It Matters: If you have high-volume needs, a slower printer could bottleneck your production process.

3.3 Print Width and Media Compatibility

- What It Is: The maximum width of the material that can pass through the machine.

- Why It Matters: Ensure the printer can handle the size of stickers or labels you plan to produce—especially if you require wide-format prints.

3.4 Connectivity and Software

- What It Is: The integration options (USB, Ethernet, Wi-Fi) and design software support.

- Why It Matters: Streamlined connections and robust software features like color management and workflow automation can significantly boost productivity.

3.5 Durability and Longevity

- What It Is: The overall build quality, warranty, and availability of replacement parts.

- Why It Matters: Frequent breakdowns or lack of manufacturer support can hamper your business operations.

If you keep these factors in mind, you’ll be able to shortlist machines that align with both your creative ambitions and your organizational objectives.

4. Types of Sticker Printer Machines

Not all sticker printer machines are created equal. Some rely on inkjets for vibrant, photo-quality prints, while others use thermal transfer for extra durability. Understanding the different printing technologies can help you make the right call.

4.1 Inkjet Sticker Printer Machines

- Overview: Uses liquid ink dispersed through microscopic nozzles.

- Pros: Exceptional color depth, smooth gradients, relatively affordable.

- Cons: Ink is generally less resistant to abrasion and may require lamination to withstand harsh environments.

4.2 Laser Sticker Printer Machines

- Overview: Utilizes static electricity to deposit toner onto media, fused by heat.

- Pros: Fast printing speeds, crisp text and line art, excellent for large runs.

- Cons: Colors may be slightly less vibrant than inkjet, especially when printing photographic images.

4.3 Thermal Transfer Sticker Printer Machines

- Overview: Uses heat to transfer solid ink from a ribbon onto the substrate.

- Pros: Offers long-lasting, fade-resistant prints; ideal for industrial labeling (e.g., barcodes, product tracking).

- Cons: Limited color range and typically more expensive ribbons.

4.4 UV and Eco-Solvent Sticker Printer Machines

- Overview: Uses specialized inks that cure instantly under UV light or inks formulated with eco-friendly solvents.

- Pros: Excellent weather resistance, vibrant colors, suitable for outdoor applications like vehicle wraps or window signage.

- Cons: Higher initial costs and generally require more complex maintenance processes.

Each type of printer technology comes with its own set of trade-offs. Your choice will hinge on how you prioritize factors like color fidelity, durability, print volume, and budget.

5. Materials and Inks for Optimal Results

The term “sticker” might make you think of flimsy paper labels, but modern sticker printer machines can handle a variety of durable, specialized media. Your choice of materials and inks can drastically influence the final product’s look, durability, and cost.

5.1 Substrate Options

- Glossy Paper: Ideal for vibrant designs with a photo-like finish.

- Matte Paper: Offers a professional, subdued look that reduces glare.

- Vinyl: Highly durable, often used for outdoor decals, product packaging, and floor graphics.

- Polyester: Resistant to harsh chemicals, making it perfect for industrial or laboratory settings.

5.2 Ink Considerations

- Dye-Based Inks: Great for bright colors but prone to fading when exposed to sunlight or moisture.

- Pigment-Based Inks: More UV-resistant, offering longer-lasting prints.

- Solvent or Latex Inks: Excellent for weather resistance, typically used for outdoor applications.

Selecting the right combination of substrate and ink ensures your stickers stay vibrant, intact, and visually striking—even in challenging environments.

6. Sticker Printer Machine Setup and Maintenance

A premium sticker printer machine is a long-term investment. Proper setup and routine care can maximize its lifespan and guarantee consistent, high-quality output.

6.1 Installation Best Practices

- Location: Place your printer in a stable, well-ventilated area to avoid dust accumulation and overheating.

- Calibration: Perform initial calibrations following the manufacturer’s guidelines, focusing on color profiles, alignment, and ink saturation.

- Software Configuration: Install and update the official drivers and design software. Many printer brands offer proprietary tools for color management and advanced layout settings.

6.2 Daily and Weekly Maintenance

- Clean the Print Heads: Prevent clogs and banding by using automated cleaning functions or manual swabs, depending on your printer type.

- Check Ink Levels and Consumables: Running low on ink mid-print can lead to streaks or color inconsistencies.

- Inspect the Media Feed: Ensure there are no debris or misalignments that could cause jams.

6.3 Long-Term Upkeep

- Replace Worn Parts: Components like rollers, belts, or fusers can degrade over time.

- Firmware Updates: Keep your printer’s firmware current to benefit from the latest performance enhancements and bug fixes.

- Professional Servicing: Some manufacturers offer annual or biannual maintenance plans that include deep cleaning and part replacements.

By adhering to these protocols, you’ll mitigate the risk of downtime and maintain the professional-quality output that sets your stickers apart in a crowded marketplace.

7. Common Applications Across Industries

Stickers might be small, but their range of applications is surprisingly vast. From small home-based crafting to large-scale commercial projects, a sticker printer machine can serve multiple roles across different sectors.

- Retail & E-commerce: Custom product labels, branded packaging, price tags, and promotional stickers.

- Food & Beverage: Compliance labels, nutritional stickers, specialty coffee bag labels, or craft beer can designs.

- Event & Marketing: Seasonal campaigns, trade show giveaways, political campaign stickers, event badges.

- Automotive & Industrial: Durable decals, safety warnings, asset tags that withstand heat, chemicals, or UV exposure.

- Crafting & Personal Use: Personalized scrapbooking stickers, stationery designs, wedding invitations, party favors.

Each application may have specific durability requirements or color expectations, so always match your materials, ink types, and printing technology to the end use.

8. Cost, ROI, and Budget Considerations

Purchasing a sticker printer machine can be a big step. However, evaluating your long-term return on investment (ROI) can clarify whether the expense makes sense for your operations or personal endeavors.

8.1 Initial Investment

Expect a wide range of price points, from a few hundred dollars for entry-level consumer models to tens of thousands for industrial-grade systems. Consider how your expected print volumes and revenue streams align with this capital outlay.

8.2 Operational Costs

- Ink or Toner: Certain machines might have high ink or toner costs but excel in print quality or speed.

- Substrates: Premium vinyl or specialty materials will cost more per unit than standard paper.

- Maintenance & Repairs: Factor in routine upkeep, replacement parts, and any service fees.

8.3 Break-Even Analysis

If you’re using the machine for business, calculate how many stickers you need to sell to recoup your investment. For instance, if your machine and setup cost $5,000 in total, and you make a $0.50 profit per sticker, you’ll need to sell 10,000 stickers to break even.

8.4 Upselling Opportunities

Having an in-house sticker printer machine opens up the potential for new product lines or services—like offering customized branding for other businesses, limited-edition releases, or personalized gifts. These additional revenue streams can expedite your ROI timeline.

9. Design and Production Best Practices

Even the most advanced sticker printer machine can’t compensate for weak design or poorly prepared files. The following best practices ensure your finished stickers look just as bold, crisp, and professional as you envision.

9.1 High-Resolution Artwork

- Use Vector Formats: Programs like Adobe Illustrator or CorelDRAW allow infinitely scalable designs without pixelation.

- 300 DPI Minimum for Raster Images: If using photos or bitmap graphics, aim for at least 300 DPI at final print size.

9.2 Color Profiles and Calibration

- CMYK vs. RGB: Remember that many printers operate in CMYK, so convert your files accordingly to avoid unexpected color shifts.

- Regular Calibration: Consistently calibrate your monitor and printer to maintain accurate color representation.

9.3 Bleeds and Margins

- Add a Safe Zone: Leave a 1/8-inch margin within the cut line to prevent essential design elements from being trimmed off.

- Bleed Zone: Extend your background or pattern beyond the final size to eliminate white edges or misalignment issues.

9.4 Cutting Options

Some printers come equipped with built-in cutters—often referred to as print-and-cut machines—streamlining the process of producing custom shapes. If you don’t have an integrated cutter, consider using external vinyl cutters or die-cutting services to achieve the desired shape.

9.5 Lamination or Protective Coatings

For stickers exposed to rough handling, moisture, or UV rays, laminating them can significantly prolong their lifespan. You can either apply a clear film laminate or use a liquid coating solution.

10. Case Studies: Real-World Success Stories

To illustrate how a sticker printer machine can transform businesses and creative projects, let’s look at a few real-world success stories.

10.1 Local Boutique Bakery

A small bakery used to outsource all of its packaging labels. Turnaround times took up to two weeks, hindering the rollout of seasonal products. After investing in a mid-range inkjet sticker printer machine, they began producing labels in-house with updated promotions and ingredients in real-time. The result? A 20% increase in sales for seasonal baked goods and a 50% reduction in packaging costs.

10.2 Home-Based Etsy Business

An Etsy seller specializing in personalized stationery struggled to keep up with custom orders. By purchasing a desktop print-and-cut sticker printer machine, they could quickly test new designs and accommodate last-minute requests. Their sales quadrupled within six months, and they expanded their offerings to include vinyl stickers for laptops and water bottles, further boosting revenue.

10.3 Manufacturing Plant

A mid-sized manufacturing plant had issues with mislabeling products due to outdated label stock. Implementing an industrial thermal transfer sticker printer machine allowed them to print durable, chemical-resistant labels on-demand. This drastically reduced labeling errors and saved thousands of dollars in rework costs.

Each case exemplifies how an appropriate sticker printer machine can dramatically improve operational efficiency and profitability, whether you’re running a local bakery or a large manufacturing plant.

FAQs About Sticker Printer Machines

Below are common questions and straightforward answers to help you further understand the ins and outs of owning a sticker printer machine.

Q1. Can I use any printer for sticker printing?

Answer: While many standard inkjet or laser printers can print on adhesive paper, they may not offer the specialized settings or durability features of a dedicated sticker printer machine. For best results, especially for commercial or heavy use, opt for a model designed specifically for stickers or labels.

Q2. Do I need special software to design stickers?

Answer: Most machines come with basic design software or a print driver. However, professional design tools like Adobe Illustrator, CorelDRAW, or Affinity Designer can give you greater control over color profiles, layering, and vector graphics.

Q3. How do I protect my stickers from fading or water damage?

Answer: Use weather-resistant inks and substrates if the stickers will face outdoor conditions. Adding a laminate or UV-coating can also significantly extend sticker life, especially in harsh or high-traffic environments.

Q4. What is the difference between sticker paper and vinyl?

Answer: Sticker paper is typically cheaper and suitable for indoor use. Vinyl is more durable, waterproof, and resistant to tears or fading, making it ideal for long-term or outdoor applications.

Q5. How often should I clean my printer to avoid clogs or banding?

Answer: Regular cleaning schedules vary by manufacturer, but many recommend weekly or bi-weekly. Rely on any built-in cleaning cycles and follow the maintenance guidelines in your user manual.

Conclusion

Investing in a sticker printer machine opens up endless possibilities—whether you’re an entrepreneur eager to scale your product branding, a designer aiming to create eye-catching decals, or a hobbyist pursuing personalized crafts. From understanding fundamental printer technologies and choosing the right materials, to mastering design best practices and scaling your operations, each step you take will strengthen your brand’s impact and make your work stand out in crowded marketplaces.

Remember, the journey doesn’t stop at purchasing a printer. Plan for routine maintenance, stay updated with the latest printing technologies, and continually refine your design approach. If you’re ready to push your creativity or business potential to the next level, consider exploring additional resources like our guide on color calibration and finishing techniques or our tutorial on advanced sticker cutting and lamination. By broadening your knowledge and perfecting your workflow, you’ll maximize the return on your investment and deliver consistently stellar results.

Ready to transform your stickers from ordinary to extraordinary? Get started by selecting the sticker printer machine that fits your needs. Once you’ve made your choice, dive into experimentation, refine your craft, and watch as beautifully printed stickers captivate your customers, boost brand recognition, and spark your own sense of creative accomplishment.

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.