Spray dryers are essential industrial tools used to convert liquid or slurry feedstock into dried particles through atomization and rapid evaporation. This comprehensive guide explores the intricate workings, various types, wide-ranging applications, advantages, disadvantages, and critical considerations for selecting the optimal spray dryer.

Understanding Spray Dryers

Spray dryer play a pivotal role in industries by transforming liquids into powders. This process involves atomizing the feedstock into fine droplets and exposing them to a hot drying medium. By doing so, spray dryers ensure precise control over particle size, shape, and moisture content, which is crucial for product formulation and downstream processing.

Historical Evolution

The origins of spray drying date back to the 19th century, with significant advancements in the early 20th century, particularly in milk powder production and during World War II for compacting food and materials. The commercialization and widespread adoption of spray dryers expanded in the latter half of the 20th century, driven by technological advancements and diverse industrial applications.

Working Principles of Spray Dryers

Spray Dryers nozzles

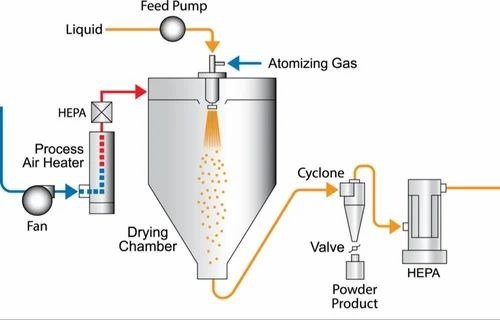

- Atomization: Liquid feedstock is atomized into small droplets using rotary or pressure nozzles, or centrifugal atomizers.

- Interaction with Drying Medium: These atomized droplets then come into direct contact with a hot air, nitrogen, or other gases within a drying chamber.

- Evaporation Process: Heat from the drying medium rapidly evaporates the moisture from the droplets, leaving behind dry particles.

- Particle Separation: The dried particles are separated from the drying gas stream using cyclone separators or bag filters, while the exhaust gases are either vented or recycled back into the system.

Types of Spray Dryers

Spray dryers are categorized based on their design and the type of drying medium employed:

- Open Cycle Spray Dryer: Utilize atmospheric air, making them suitable for drying materials resistant to high temperatures.

- Closed Cycle Spray Dryer: Recirculate heated gases, offering precise control and ideal for drying heat-sensitive materials.

- Pressure Spray Dryer: Operate at elevated pressures, enabling the production of powders with specific characteristics or handling of sensitive materials.

Applications Across Industries

Spray dryers are indispensable across various sectors due to their versatility and efficiency:

- Food Industry: Used in the production of instant coffee, milk powder, flavors, and encapsulated products.

- Pharmaceuticals: Essential for drying antibiotics, vitamins, and pharmaceutical formulations to enhance stability and shelf life.

- Chemicals: Employed in manufacturing detergents, pigments, ceramics, and catalysts.

- Environmental Applications: Vital for treating industrial waste and drying wastewater sludge to reduce volume and facilitate disposal.

Spray Dryer

Specialized Applications

- Milk Production: Converts liquid milk into powdered form, extending shelf life and facilitating transportation.

- Pharmaceutical Formulations: Produces powdered medicines and formulations that require controlled drying conditions.

- Pilot Scale and Lab Scale Spray Dryers: Utilized in research and development settings for testing new formulations and processes on a smaller scale.

Advantages of Spray Dryers

Spray dryers offer numerous advantages that contribute to their widespread adoption in industrial processes:

- Efficiency: Rapid drying rates and continuous operation improve productivity and throughput.

- Quality Control: Uniform particle size distribution ensures consistency and quality of the final product.

- Flexibility: Capable of handling a wide range of feedstock viscosities and compositions.

- Economic Benefits: Reduces energy consumption compared to alternative drying methods and minimizes product loss during processing.

Disadvantages of Spray Dryers

Despite their advantages, spray dryer have certain limitations and challenges:

- Viscosity Constraints: Effective primarily for feedstocks with viscosity below 500 centipoises, often requiring pre-treatment or dilution for proper atomization.

- Cost Considerations: Initial capital investment and operational costs can be high due to the energy-intensive nature of the drying process.

- Safety Concerns: Handling potentially explosive or flammable materials requires robust safety measures and equipment design.

Conclusion

In conclusion, spray dryers are integral to modern industrial processes, offering efficient and effective solutions for drying various materials across diverse industries. Understanding their operational principles, types, applications, advantages, disadvantages, and selection criteria is essential for optimizing drying processes and achieving desired product outcomes.

For further insights into spray dryer and industrial drying technologies, visit EngiTech. Explore our comprehensive resources and stay updated on the latest innovations and applications in industrial drying.