The Ultimate Guide to Soap Making Machines: Types, Features, and Buying Tips

Soap production has evolved significantly from traditional handmade processes to advanced industrial automation. Whether you’re a small business, a large-scale manufacturer, or an entrepreneur entering the soap-making industry, investing in the right soap making machine can enhance efficiency, quality, and profitability.

In this comprehensive guide, we’ll explore the different types of soap making machines, their functions, key features to consider, and essential tips for purchasing the best equipment to meet your needs.

Table of Contents

Understanding Soap Making Machines

Soap making machines are designed to handle different stages of the soap production process, from raw material processing to final packaging. The automation level varies based on production scale, with options available for small-scale, medium-scale, and large-scale manufacturing.

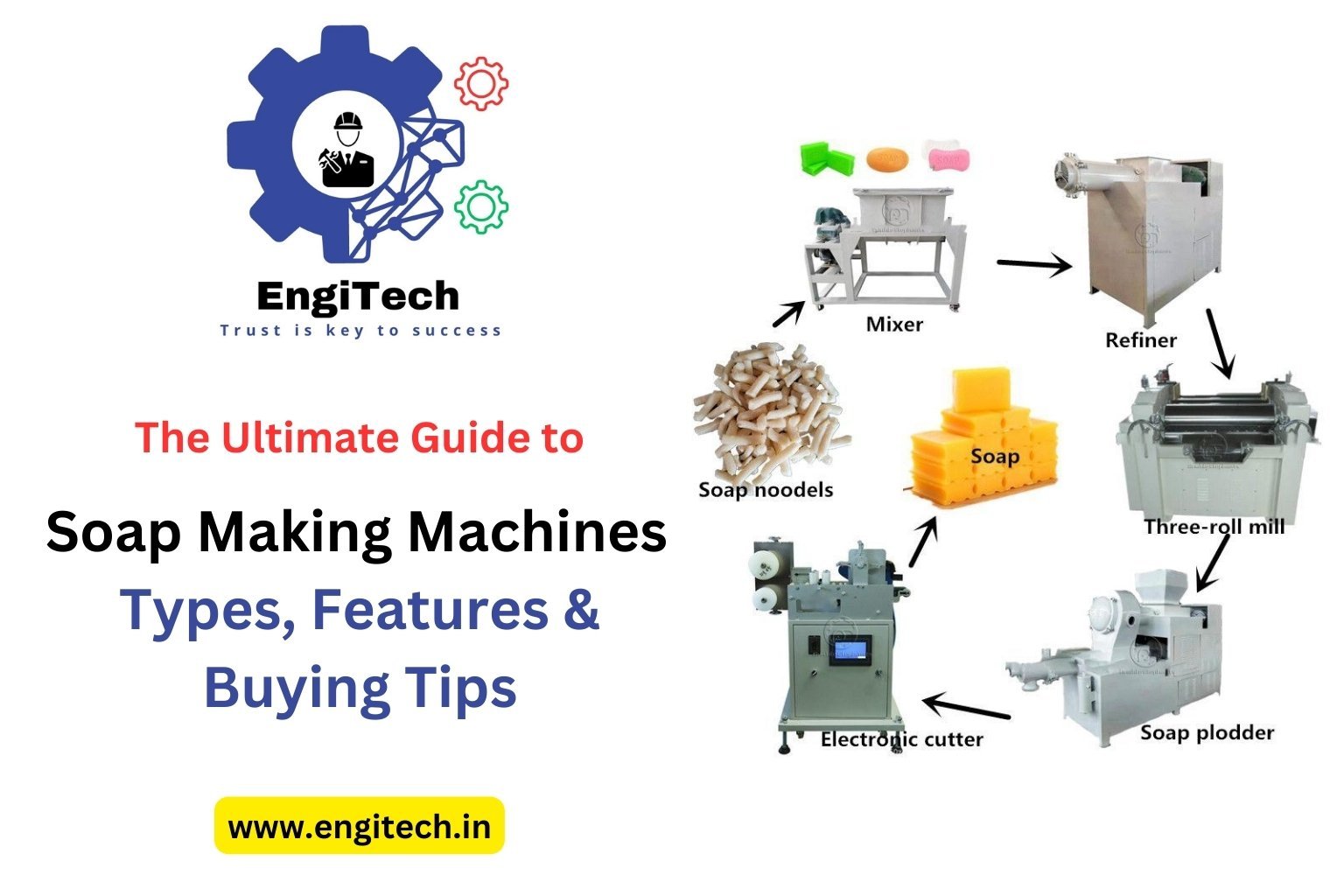

Types of Soap Making Machines

- Soap Mixer Machine

- Mixes raw materials such as oils, fats, and lye.

- Ensures homogeneity in the soap formulation.

- Soap Plodder/Extruder Machine

- Compresses and extrudes soap mass into solid bars.

- Available in single-stage and double-stage configurations.

- Soap Cutting Machine

- Precisely cuts extruded soap into uniform bars.

- Manual, semi-automatic, and fully automated models available.

- Soap Stamping Machine

- Engraves brand logos and designs onto soap bars.

- Enhances the visual appeal and brand identity.

- Soap Drying Machine

- Reduces moisture content to improve hardness and shelf life.

- Common types include vacuum dryers and hot air dryers.

- Soap Packaging Machine

- Wraps and seals soap bars for distribution.

- Includes flow wrap machines, shrink wrap machines, and carton packing machines.

Key Features to Consider When Choosing a Soap Making Machine

1. Production Capacity

- Select a machine that aligns with your daily or monthly output requirements.

- Consider scalability if future expansion is planned.

2. Level of Automation

- Manual machines: Best for small-scale businesses and artisans.

- Semi-automatic machines: Balance between manual control and efficiency.

- Fully automatic machines: Ideal for large-scale industrial production with minimal labor involvement.

3. Material and Build Quality

- Machines made from stainless steel offer durability and resistance to corrosion.

- Ensure high-quality components to minimize maintenance and downtime.

4. Power Consumption

- Energy-efficient models help reduce operational costs.

- Check the power rating and compare it with your facility’s electricity supply.

5. Customization and Flexibility

- Look for machines that allow adjustments in soap size, shape, and formulation.

- Compatibility with different raw materials is a plus.

6. Ease of Maintenance

- Machines with user-friendly designs and easy-to-clean components save time and effort.

- Availability of spare parts and manufacturer support should be considered.

Steps in the Industrial Soap Making Process

- Mixing: Oils, fats, and lye are blended in the soap mixer machine.

- Saponification: The chemical reaction forms soap and glycerin.

- Drying: Moisture content is reduced using a soap drying machine.

- Extrusion: The soap mass is shaped into logs via a soap plodder/extruder.

- Cutting: Soap logs are sliced into uniform bars using a cutting machine.

- Stamping: Bars are embossed with logos and branding via a stamping machine.

- Packaging: The final product is wrapped and packed for distribution.

Buying Tips for Soap Making Machines

- Assess Your Needs: Determine the production scale and level of automation required.

- Check Manufacturer Reputation: Choose reputable manufacturers known for quality and after-sales support.

- Request Product Demonstrations: Seeing the machine in action helps evaluate performance.

- Compare Prices and Warranty: Ensure you get value for money with a reliable warranty period.

- Verify Compliance: Machines should adhere to industry standards and safety regulations.

Frequently Asked Questions (FAQs) About Soap Making Machines

1. What is the best soap making machine for small businesses?

- The best machine depends on production needs. Manual or semi-automatic machines are ideal for small-scale businesses.

2. How much does a soap making machine cost?

- Prices vary based on capacity and automation level, ranging from a few thousand to several hundred thousand dollars.

3. What raw materials are needed for soap production?

- Common ingredients include oils, fats, lye (sodium hydroxide), fragrances, and colorants.

4. How does a soap plodder machine work?

- It compresses soap mixture and extrudes it into solid bars before cutting and stamping.

5. What is the difference between hot process and cold process soap making?

- Hot process involves heat application, speeding up curing time, while cold process relies on natural saponification over weeks.

6. How can I ensure my soap making machine lasts longer?

- Regular maintenance, proper cleaning, and using high-quality raw materials can extend machine life.

7. Where can I buy a high-quality soap making machine?

- Reputable manufacturers, online marketplaces, and industrial suppliers offer a range of options to suit various budgets and requirements.

Conclusion

Investing in the right soap making machine is crucial for efficient production and high-quality soap manufacturing. Whether you’re setting up a small-scale operation or expanding a large production line, understanding machine types, key features, and buying considerations will help you make an informed decision.

For more insights on industrial machinery, visit EngiTech, where we provide expert guidance and the latest innovations in manufacturing equipment.