In wastewater treatment, there’s a silent byproduct that often gets overlooked—sludge. It quietly accumulates at the bottom of clarifiers, digesters, and sedimentation tanks. And if you don’t manage it properly, it can lead to skyrocketing operational costs, permit violations, and environmental harm.

In fact, untreated or poorly handled sludge contributes to over 50% of the total cost of operating a wastewater treatment facility.

That’s where sludge dewatering comes into play.

Whether you’re managing a municipal sewage plant, running an industrial effluent treatment unit, or planning to upgrade your sludge management strategy, understanding sludge dewatering is critical. It allows you to:

- Reduce sludge volume by up to 80%

- Lower hauling and disposal costs

- Improve energy recovery

- Meet compliance requirements with ease

In this guide, you’ll discover:

- What sludge dewatering really is and how it works

- Key methods used in industries and municipalities

- Common mistakes that operators make (and how to avoid them)

- Real-world examples and first-hand insights

Let’s begin by understanding the basics.

Table of Contents

What Is Sludge Dewatering and Why It Matters

Sludge dewatering is the process of removing water from sludge to reduce its volume and weight, making it easier and more cost-effective to handle, transport, and dispose of.

In simpler terms, it’s about turning thick, wet waste into a drier, more manageable solid cake.

Why Is It So Important?

Because raw sludge is:

- Heavy – It can be up to 99% water.

- Expensive to transport – Water is weight, and weight costs money.

- Difficult to dispose of – Many landfills or treatment plants reject liquid waste.

By removing moisture, sludge dewatering transforms waste into something you can:

- Safely dispose of

- Reuse as compost or fuel

- Process further (e.g., incineration, drying, pelletization)

Environmental and Operational Impact

Proper sludge dewatering:

- Reduces landfill demand

- Minimizes greenhouse gas emissions

- Cuts down pathogen risk

- Lowers overall wastewater treatment costs by up to 30%

From a regulatory standpoint, most government agencies (like the EPA in the U.S. or CPCB in India) require sludge to meet certain moisture and stability criteria before it can be transported or land-applied.

A Hidden Source of Value

Here’s something many don’t realize: Dewatered sludge isn’t just waste. In some sectors, it’s treated as a resource.

- In cement plants, dried sludge can be used as alternative fuel.

- In agriculture, treated biosolids may serve as nutrient-rich compost.

- In energy plants, sludge can undergo anaerobic digestion to produce biogas.

In all these cases, dewatering is the first and necessary step toward reuse.

Common Sludge Dewatering Methods

There is no one-size-fits-all approach to sludge dewatering. The right method depends on several factors—such as the type of sludge, desired dryness level, available space, energy budget, and discharge regulations.

Here’s a breakdown of the most commonly used sludge dewatering methods across industries and municipalities, along with their benefits, limitations, and ideal use cases.

1. Gravity Dewatering

Gravity-based dewatering is the oldest and simplest technique. It relies on natural drainage and evaporation to remove moisture from sludge.

a) Drying Beds

- Shallow sand and gravel beds where sludge is spread and left to dry under the sun.

- Common in rural or semi-urban STPs.

Pros:

- Low cost

- Low energy consumption

Cons:

- Slow process (can take 10–15 days)

- Requires large land area

- Weather-dependent

Best For: Small to mid-sized STPs, especially in warm, dry climates

b) Settling Lagoons

- Large open basins where sludge settles, and water is decanted.

Use Cases: Agriculture-based treatment systems and pre-thickening in large municipal plants

2. Mechanical Dewatering

Mechanical systems are designed to handle larger volumes and achieve higher solids concentration. These are ideal for industrial wastewater treatment plants, municipal WWTPs, and zero liquid discharge (ZLD) systems.

a) Filter Press

- Uses pressure to squeeze water out of sludge between filter plates.

- Produces dry cakes with 25–40% solids content.

Pros:

- High dryness levels

- Compact footprint

Cons:

- Labor-intensive

- Requires regular maintenance of filter cloths

Best For: Chemical industries, ETPs with high solid loads, CETPs

b) Belt Filter Press

- Sludge is sandwiched between two porous belts and passed through rollers to remove water.

Pros:

- Continuous operation

- Moderate dryness

Cons:

- Larger footprint than filter press

- Limited performance on very fine sludge

Best For: Municipal STPs, paper & pulp industries

c) Decanter Centrifuge

- Uses centrifugal force to separate solids from water.

Pros:

- High throughput

- Fully automatic

- Compact design

Cons:

- High energy use

- Sensitive to feed variability

Best For: Pharma, dairy, oil sludge, and high-speed operations

3. Thermal and Solar Drying

These methods aim to further reduce moisture content in already dewatered sludge, especially when it’s intended for reuse or energy recovery.

a) Paddle Dryer

- A closed, indirect-heating system that dries sludge using heated paddles and hollow shafts.

- Achieves over 90% dryness.

Pros:

- Compact design

- No direct contact with hot air (safer, cleaner)

- Recycles vapors for energy savings

Cons:

- Higher capital cost

- Requires thermic fluid or steam

Best For: Industrial plants aiming for fuel-grade sludge or volume reduction

b) Solar Drying Tunnels

- Uses greenhouse-like structures to dry sludge using solar energy.

Pros:

- Energy-efficient

- Sustainable

Cons:

- Weather-dependent

- Requires a large area

Best For: Areas with high solar radiation, eco-focused facilities

c) Thermal Belt Dryer

- Uses hot air over a conveyor system to dry sludge cakes.

Use Case: When space is limited but high dryness is needed

Comparison Table: Sludge Dewatering Methods

| Method | Dryness (%) | CapEx | Opex | Footprint | Automation | Ideal For |

|---|---|---|---|---|---|---|

| Drying Beds | 15–25 | Low | Very Low | High | No | Rural STPs, warm climates |

| Filter Press | 25–40 | Medium | Medium | Low | Semi-auto | Chemical, textile industries |

| Belt Filter Press | 18–30 | Medium | Medium | Medium | Yes | Large STPs |

| Centrifuge | 20–35 | High | High | Low | Full | Pharma, oil, dairy sludge |

| Paddle Dryer | 85–95 | High | Medium | Low | Full | ZLD, fuel-grade sludge, industries |

| Solar Drying Tunnel | 30–60 | Medium | Low | High | No | Eco-projects, space-available areas |

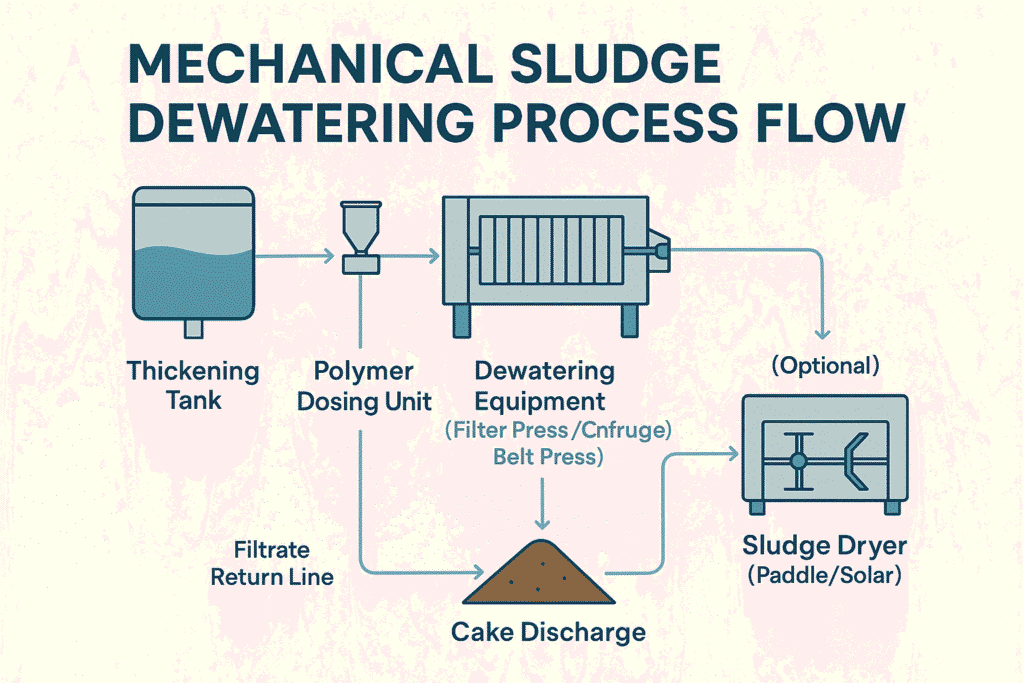

Step-by-Step Process in Mechanical Dewatering

Mechanical sludge dewatering is more than just pressing water out of waste—it’s a systematic process involving physical, chemical, and operational elements. Each step is critical to achieving optimal solids recovery, minimizing operating costs, and ensuring regulatory compliance.

Here’s a breakdown of the end-to-end dewatering process in most municipal and industrial settings.

Step 1: Sludge Thickening (Optional but Recommended)

Before dewatering, sludge is usually thickened to increase its solids concentration and reduce the load on the dewatering equipment.

Methods Used:

- Gravity thickening

- Dissolved air flotation (DAF)

- Drum thickeners

Why It Matters:

Thickening reduces volume by 30–50% and makes downstream dewatering far more energy-efficient.

Step 2: Chemical Conditioning or Flocculation

To improve separation efficiency, polymer or lime-based chemicals are added to the sludge. These help bind fine particles into larger flocs, making them easier to filter or centrifuge.

Typical Chemicals:

- Cationic or anionic polymers

- Ferric chloride

- Lime

Key Tip:

Always conduct jar testing to determine the correct type and dose of chemical. Overdosing can lead to poor cake formation and increased chemical costs.

Step 3: Dewatering Equipment Operation

Once conditioned, the sludge is fed into the chosen mechanical equipment. Let’s look at the core types:

a) Filter Press

- Sludge is pumped between filter plates lined with filter cloth.

- Hydraulic pressure squeezes water out.

- Solid “cake” is discharged manually or semi-automatically.

b) Belt Filter Press

- Sludge is sandwiched between two moving belts.

- It passes through gravity drainage, wedge zones, and high-pressure rollers.

- Dewatered cake drops into a bin or conveyor.

c) Decanter Centrifuge

- Sludge is rotated at high speed.

- Solids are forced outward and collected.

- Water is discharged separately.

Key Parameters to Monitor:

- Feed flow rate (m³/hr)

- Cake dryness (% solids)

- Filtrate clarity

- Polymer dosage (g/ton of dry solids)

Step 4: Cake Handling and Transport

Once sludge is dewatered, the solid cake needs to be handled, transported, or reused.

Common Options:

- Bin or container storage

- Conveyor belts for automated transfer

- Bagging systems

- Further drying via paddle dryer or solar tunnel (if fuel or reuse is intended)

Disposal Methods:

- Landfill (if permitted)

- Composting (for biosolids)

- Incineration or co-processing in cement kilns

Step 5: Filtrate or Centrate Management

The liquid that separates during dewatering (filtrate or centrate) often contains residual organics and fine solids.

Treatment Options:

- Return to the head of the WWTP

- Send to polishing treatment (e.g., MBBR, RO)

- pH adjustment and nutrient removal, if required

Optional Step: Sludge Drying (Post-Dewatering)

If you’re targeting very low moisture content or planning to reuse sludge as fuel, further drying is needed.

Example: Paddle Dryer Integration

- Uses thermic fluid or steam

- Reduces moisture to <10%

- Produces granular, pathogen-free output

- Suitable for ZLD systems and WTE (Waste-to-Energy) applications

Key Equipment and Technologies in Sludge Dewatering

Selecting the right dewatering equipment is one of the most important decisions in any wastewater or sludge management project. The right technology not only determines the final dryness of the sludge cake but also affects energy costs, polymer usage, operator effort, and overall plant efficiency.

Here’s a detailed look at the most widely used sludge dewatering technologies, including how they work, their ideal applications, and what to watch for.

1. Filter Press

A filter press is a batch-operated, pressure-driven system that removes water from sludge using filter cloths pressed between plates.

Working Principle:

- Sludge is pumped into chambers between plates.

- Water is forced out through filter cloths under high pressure.

- The remaining solids form a dense, semi-dry cake.

Typical Cake Solids: 25–40%

Automation: Manual to semi-automatic

Best Used In: Chemical industries, electroplating, ETPs with high solid loads

Pros:

- High solids content

- Effective for oily or sticky sludge

Cons:

- Labor-intensive

- Frequent cloth washing needed

2. Belt Filter Press

This continuous dewatering system uses gravity and pressure to remove water from sludge. It’s often preferred in municipal sewage treatment plants.

Working Principle:

- Sludge is flocculated with polymer and fed onto a moving belt.

- Water drains by gravity, then by squeezing between tensioned belts.

Typical Cake Solids: 18–30%

Automation: Fully automatic

Best Used In: Municipal STPs, pulp and paper, food industry

Pros:

- Continuous operation

- Lower energy consumption than centrifuge

Cons:

- Not ideal for very fine or oily sludge

- Requires large space

3. Decanter Centrifuge

This high-speed machine uses centrifugal force to separate solids from liquids. It’s widely used in industrial settings with space limitations or high flow rates.

Working Principle:

- Sludge is spun at high RPM inside a horizontal drum.

- Solids are pushed to the outer wall and discharged separately from liquid.

Typical Cake Solids: 20–35%

Automation: Fully automatic

Best Used In: Oil & gas, pharma, dairy, textile sludge

Pros:

- Compact footprint

- High throughput

- Fully enclosed system (no odor)

Cons:

- High power consumption

- Sensitive to feed characteristics

4. Screw Press

An energy-efficient alternative gaining popularity for small to mid-sized operations.

Working Principle:

- A slow-rotating screw conveys sludge through a narrowing space, squeezing water out gradually.

- Works under low RPM, resulting in low wear and maintenance.

Typical Cake Solids: 15–25%

Automation: Fully automatic

Best Used In: STPs under 100 KLD, decentralised WWTPs, resorts, housing societies

Pros:

- Low energy use

- Quiet operation

- Easy to maintain

Cons:

- Lower dryness compared to filter press

- May need pre-thickening

5. Paddle Dryer (for Post-Dewatering Drying)

While not a primary dewatering machine, the paddle dryer is a game-changer for plants looking to achieve high dryness levels (>85%), especially for:

- Waste-to-energy conversion

- Sludge-to-fuel programs

- ZLD (Zero Liquid Discharge) systems

Working Principle:

- Uses indirect heating via thermic fluid or steam through hollow shafts and paddles.

- Ensures uniform drying and vapor containment.

Typical Cake Solids (after drying): >90%

Automation: Fully automatic

Best Used In: Industrial ETPs, power plants, cement units, oil refineries

Pros:

- Odor-free and enclosed

- Allows fuel reuse of dried sludge

- Compact and efficient

Cons:

- Higher CapEx

- Needs thermal energy input

Quick Comparison: Equipment at a Glance

| Equipment | Cake Solids (%) | Automation | Footprint | Energy Use | Best For |

|---|---|---|---|---|---|

| Filter Press | 25–40 | Semi-auto | Low | Medium | Chemical, textile, CETPs |

| Belt Filter Press | 18–30 | Full | High | Low | Municipal, pulp & paper |

| Decanter Centrifuge | 20–35 | Full | Low | High | Pharma, oil sludge, dairy |

| Screw Press | 15–25 | Full | Low | Very Low | Small STPs, housing societies |

| Paddle Dryer | >85 (post-drying) | Full | Low | Medium-High | ZLD, fuel-grade sludge recovery |

Common Mistakes and Misconceptions in Sludge Dewatering

Even the most advanced dewatering systems can underperform if implemented with incorrect assumptions or poor practices. Unfortunately, many wastewater professionals make critical decisions based on myths, outdated knowledge, or cost-driven shortcuts—resulting in increased operational costs, equipment failures, and non-compliance.

Let’s uncover some of the most frequent mistakes and how to avoid them.

1. Assuming All Sludge Can Be Treated the Same Way

This is one of the most common errors. Sludge composition varies widely depending on:

- Industry (e.g., pharma, textile, dairy)

- Biological or chemical treatment used upstream

- Floc characteristics and viscosity

Why It’s a Problem:

Selecting a filter press when your sludge has fine suspended solids or high oil content can cause clogging, poor cake formation, and increased maintenance.

Solution:

Always perform sludge characterization tests before finalizing the dewatering equipment.

2. Ignoring Chemical Conditioning

Some operators believe mechanical equipment alone is enough to remove water. In reality, chemical conditioning (flocculation) is essential for:

- Aggregating fine particles

- Enhancing dewatering efficiency

- Improving cake dryness

Common Pitfall:

Using generic polymers without testing. This often leads to excess polymer consumption or ineffective separation.

Solution:

Conduct jar testing for every new batch of sludge and optimize polymer dosing.

3. Undersizing the Dewatering System

To cut costs, some plants install smaller units than needed, hoping they can “make do.”

What Happens Next?

- Equipment overload

- Frequent breakdowns

- Poor filtrate quality and incomplete dewatering

Solution:

Size your system based on peak sludge generation (not average), include future expansion needs, and incorporate buffer storage tanks.

4. Treating Sludge Dewatering as a Low-Priority Add-On

Some project owners treat sludge dewatering as optional or leave it out of the original scope.

Consequence:

- Accumulated sludge creates bottlenecks

- Transport and disposal costs skyrocket

- Sludge storage becomes an industrial environmental and legal risk

Solution:

Include sludge dewatering in the initial design phase and treat it as a core part of the wastewater treatment process.

5. No Plan for Cake Disposal or Reuse

Dewatering only solves half the problem. The other half is what you do with the dewatered cake.

Common Mistakes:

- No tie-up with authorized landfill or TSDF

- Stockpiling sludge on-site, risking groundwater pollution

- Overlooking fuel recovery or composting opportunities

Solution:

Design a complete sludge management plan that includes:

- Cake transport

- Drying or co-processing

- Land application or industrial reuse

6. Over-Reliance on Manual Operation

In older plants, manual cake discharge, polymer dosing, and filter maintenance can lead to:

- Operator fatigue

- Inconsistent performance

- High error rates

Solution:

Automate wherever possible. Modern systems include:

- PLC-based control panels

- SCADA monitoring

- Remote alerts for feed rate, pH, torque, and filter status

7. Inadequate Training for Operators

Even the best-designed plant will fail if operated by an untrained team. Poor practices include:

- Improper startup/shutdown sequences

- Skipping chemical preparation steps

- Ignoring critical alarms

Solution:

Schedule monthly operator training, display SOPs onsite, and ensure support from equipment vendors for troubleshooting.

8. Not Monitoring Performance Metrics

Without regular monitoring, plants often don’t realize they’re operating inefficiently until costs or compliance issues arise.

Key KPIs to Track:

- Cake dryness (% solids)

- Polymer dosage (g/kg of dry solids)

- Filtrate turbidity

- Specific energy consumption (kWh/ton of dry solids)

Summary Table: Mistakes & Solutions

| Mistake | Why It Happens | How to Fix It |

|---|---|---|

| One-size-fits-all sludge treatment | Lack of lab testing | Conduct sludge profiling |

| No chemical dosing or overdosing | Assumptions, poor advice | Use jar testing & dose control systems |

| Undersized equipment | Budget-driven design | Size based on peak load, not average |

| Ignoring disposal plan | Not in scope or underestimated | Plan cake reuse/disposal at design stage |

| Manual dependency | Low investment | Upgrade to semi or full automation |

| No operator training | High staff turnover | Regular vendor-led and internal training |

Personal Story: What I Learned Visiting a Sludge Dewatering Plant in Maharashtra

A few years ago, I was invited to review the performance of a sludge dewatering system installed at a mid-sized chemical manufacturing plant in Maharashtra. The plant had recently expanded operations, and while the effluent treatment plant (ETP) was upgraded, the sludge handling system was struggling to keep up.

The Setup Looked Good—On Paper

The facility had invested in a filter press capable of handling up to 10,000 liters of sludge per day. It had a decent layout:

- A polymer preparation unit

- Sludge holding tank

- Filter press with semi-automatic cake discharge

- Collection bins for dried cake

Everything seemed well-aligned with the industry standard. Yet, within just 15 minutes of being on-site, it became clear something wasn’t right.

What Was Going Wrong

The first red flag was the excessive moisture in the sludge cake—nearly 80% water when it should’ve been closer to 60–65% at the very least.

I asked the plant team about polymer dosing. Their answer?

“We use the same dosage daily. It works fine most of the time.”

Except, sludge isn’t static. It varies by production batch, cleaning cycle, and upstream processes.

Then came the second issue: frequent clogging of filter cloths. Operators had been overdosing polymer, assuming more would help—when in fact, it created a sticky, jelly-like layer that reduced filtration efficiency.

Finally, the filter press was running only one batch per shift, even though sludge generation was twice that volume. The plant had no real-time tracking, and sludge was backing up into holding tanks.

What We Did to Fix It

We made a few simple but impactful changes:

- Introduced jar testing twice a week to calibrate polymer dose accurately.

- Implemented a flow meter and sludge level sensor to optimize batch timing.

- Trained operators on cloth cleaning techniques and preventive maintenance.

- Staggered operations to avoid downtime and match generation with dewatering.

The Results—In Just 90 Days

- Polymer consumption dropped by 22%

- Cake dryness improved from 20% to 33%

- Filter press downtime reduced by 60%

- Sludge handling costs decreased by nearly ₹40,000/month

- No overflow incidents or environmental violations

But the most impressive change?

The plant team became confident, proactive, and fully engaged in sludge management. What was earlier treated as a nuisance became a measurable performance metric.

My Takeaway: You Don’t Need Expensive Upgrades—You Need Awareness

The plant didn’t install new machinery or adopt cutting-edge automation.

It simply began to treat sludge dewatering as a core part of the process, not an afterthought.

And that’s the mindset every facility—big or small—needs to adopt.

Sludge Dewatering vs. Sludge Incineration: Which Is Right for You?

After sludge has been separated from wastewater, the next challenge is what to do with it. While sludge dewatering focuses on reducing water content to minimize volume and handling costs, sludge incineration goes a step further—it aims to eliminate the organic content entirely through controlled combustion.

Both methods serve different goals, and choosing between them depends on multiple factors: cost, environmental goals, regulatory demands, and end-use strategy.

What Is Sludge Incineration?

Sludge incineration is the process of combusting dewatered sludge at high temperatures (typically above 850°C) in dedicated incinerators. The result is a small volume of inert ash, with significant reduction in:

- Mass (up to 90%)

- Volume (up to 95%)

- Pathogens and volatile organics

Incineration systems may include:

- Fluidized bed incinerators

- Multiple hearth furnaces

- Rotary kilns (used in cement and power plants)

Core Differences at a Glance

| Parameter | Sludge Dewatering | Sludge Incineration |

|---|---|---|

| Purpose | Remove moisture | Destroy organics and reduce mass |

| Final Output | Semi-dry sludge cake | Ash residue |

| Moisture Reduction | Up to 85–90% (with drying) | 100% (combustion) |

| Energy Use | Low to medium | High (thermal input required) |

| CapEx | Low to medium | Very high |

| O&M Complexity | Moderate | High (requires trained staff, air controls) |

| Environmental Impact | Low (if cake is disposed or reused safely) | Potential air pollution (requires scrubbers) |

| Best Use Cases | Small/medium STPs, Industrial WWTPs | Large cities, refineries, ZLD plants |

| Sludge Reuse Options | Compost, fuel, landfill | Cement kiln feed, landfill ash |

When to Choose Dewatering Alone

You should focus solely on dewatering if:

- Your plant generates sludge volumes under 10 TPD (tons per day)

- You plan to reuse sludge as fuel or compost

- You have access to approved landfill or TSDF (Treatment, Storage, and Disposal Facility)

- Your primary goal is cost savings and operational simplicity

Dewatering—especially when enhanced with paddle dryers—can produce sludge with <10% moisture content, suitable for:

- Co-processing in cement kilns

- Use as auxiliary fuel in boilers

- Land application, where permitted

When Incineration Becomes Necessary

Consider sludge incineration when:

- You’re operating at high scale (e.g., metro cities, refineries, CETPs)

- Pathogen destruction and volume minimization are critical

- Land for landfill or drying is limited

- You’re required to comply with strict biosolid disposal norms

It’s commonly used in:

- Europe and Japan (due to land scarcity)

- India’s proposed urban ZLD corridors

- Hazardous sludge treatment from pharma and chemical sectors

However, incineration requires:

- High capital investment

- Advanced emission control systems (scrubbers, filters)

- Continuous monitoring under pollution control board standards

Environmental Considerations

| Factor | Dewatering with Reuse | Incineration |

|---|---|---|

| GHG Emissions | Low | High (unless waste heat is recovered) |

| Odor Control | High (enclosed systems) | Very High (must have air scrubbers) |

| Residue Toxicity | Low to Moderate | Low (inert ash, but disposal needed) |

In some progressive WWTPs, a hybrid model is adopted:

- Dewatering → Drying → Incineration or co-processing

This allows recovery of heat, reduction of environmental impact, and regulatory compliance.

Expert Perspective: Cost-Benefit Analysis

If your primary goal is:

- Cost-effective sludge volume reduction

- Safe reuse or disposal

Then dewatering + optional drying is ideal.

But if your plant handles:

- Pathogen-laden biosolids

- Hazardous industrial sludge

- Large volumes with no reuse potential

Then incineration, while expensive, may be the only compliant long-term option.

Case Study: How an Industrial Plant Reduced Sludge Disposal Costs with Dewatering and Paddle Drying

Background:

In 2022, a specialty chemical manufacturing company in Gujarat was dealing with a growing sludge problem. Their on-site effluent treatment plant (ETP) generated around 15 tons of sludge per day, much of it semi-liquid with over 80% moisture.

The sludge:

- Required daily transport to an authorized landfill

- Had high transport costs due to weight and bulk

- Failed to meet new moisture-level regulations issued by the local pollution control board

Despite having a basic filter press in place, the final cake still contained too much residual moisture, and the cost of handling and disposal was rising each month.

Challenges Faced:

- High transport costs (₹2.5–3 lakhs/month)

- Non-compliance with landfill moisture norms

- Frequent clogging and maintenance issues with the existing dewatering unit

- Limited space to expand sludge storage

Solution: Integration of a Paddle Dryer Post-Dewatering

After evaluating various options, the plant management decided to install a paddle dryer downstream of the filter press. This decision was based on:

- A need for compact design

- Enclosed operation (no odor or emissions)

- Ability to handle semi-solid sludge with high moisture content

- Reuse potential of dried sludge as auxiliary fuel

Implementation Plan:

- Filter press retained as primary dewatering unit

- Dried cake from filter press conveyed to a dual-shaft paddle dryer

- Thermic fluid system used as the heat source

- Vapor recovery unit installed to condense and recycle moisture

- Final dried sludge stored in silos for dispatch

Results Achieved (within 4 months):

| Parameter | Before | After Paddle Dryer |

|---|---|---|

| Sludge moisture (%) | 75–80 | <15 |

| Sludge volume per day | 15 tons | 4–5 tons |

| Monthly transport cost | ₹2.8 lakhs | ₹90,000 |

| Environmental compliance | Failed | Fully compliant |

| Sludge reuse | Not possible | Used as fuel in local cement kiln |

| Operator requirement | 3 per shift | 1 per shift (automated system) |

Additional Benefits:

- No odor or air pollution thanks to enclosed paddle drying system

- Energy cost savings by using recovered condensate to preheat fluid

- Carbon credit eligibility through reduced landfill volume and fuel substitution

- Improved plant reputation among regulatory authorities and industry peers

Lessons Learned:

- Dewatering alone is often not enough—especially when sludge needs to be reused or meet strict disposal norms.

- Compact dryers like paddle systems can provide high dryness levels without consuming too much space or energy.

- Integrated planning (from thickening to final disposal) reduces surprises, costs, and downtime.

- Dry sludge is not waste—it’s a resource when handled correctly.

Tips for Beginners: How to Set Up a Sludge Dewatering System

Starting from scratch? Whether you’re managing a small ETP, a housing society’s STP, or an industrial ZLD facility, sludge dewatering can seem complex—but it doesn’t have to be.

Here’s a simplified, step-by-step roadmap designed for first-time implementers.

1. Start with a Sludge Characterization Study

Before selecting any equipment, test your sludge to understand:

- Solids concentration (% dry solids)

- Oil and grease content

- pH, viscosity, and particle size

- Seasonal variations (some industries fluctuate batch-wise)

Why it matters:

Your sludge type determines everything—from flocculant choice to the dewatering method and final disposal plan.

2. Select the Right Equipment (Not Just the Cheapest)

Common options:

- Filter press – for moderate dryness and low CapEx

- Screw press – for low-load, decentralized plants

- Belt press – for high-volume, low-pressure needs

- Centrifuge – for oily or fine particulate sludge

- Paddle dryer – for post-dewatering drying to achieve <15% moisture

Tip: Always evaluate based on:

- Throughput

- Energy use

- Operator skill required

- Maintenance frequency

- Cake dryness goal

3. Plan for Chemical Conditioning

Don’t assume sludge will dewater without assistance.

- Conduct jar testing to select the right polymer or coagulant.

- Design a chemical dosing station with proper storage, mixing, and safety protocols.

- Automate dosage based on feed rate, where possible.

4. Allocate Space Wisely

Dewatering equipment requires:

- Inlet sludge tank

- Polymer preparation unit

- Dewatering machine + filter cake area

- Filtrate handling (back to ETP or separate polishing)

- Covered or enclosed sludge storage

- If drying, space for a paddle dryer or drying beds

Don’t forget: Include floor drains, ventilation, and chemical spill controls.

5. Ensure Operator Training and SOPs

Your system is only as good as the people running it.

- Display standard operating procedures (SOPs) near control panels.

- Train operators on:

- Chemical handling

- Filter cloth cleaning

- Emergency shutdown protocols

- Schedule quarterly performance reviews and retraining

6. Design for Maintenance and Redundancy

Nothing disrupts a WWTP faster than a blocked dewatering unit.

- Keep filter cloths, bearings, and polymer spares in stock

- Design bypass lines or duplicate units for continuous operation

- Set alerts for high pressure, flow drop, or feed tank overflow

7. Plan for Sludge Disposal or Reuse from Day One

Dewatering solves the water problem, but the solids still need to go somewhere.

- Partner with a TSDF or landfill operator

- Consider fuel reuse options (if dried)

- Explore composting or co-processing (for biosolids or non-toxic sludge)

8. Monitor and Improve Continuously

Install:

- Flow meters

- Cake dryness monitoring (manual or online)

- pH and conductivity sensors in filtrate

Review:

- Daily logs

- Monthly sludge production vs. disposal records

- Polymer and energy use

Use this data to optimize performance, cut costs, and stay compliant.

Beginner’s Checklist

| Task | Status |

|---|---|

| Sludge lab testing done | ✅ |

| Equipment type shortlisted | ✅ |

| Chemical dosing setup planned | ✅ |

| Layout finalized | ✅ |

| Operator training scheduled | ✅ |

| Disposal tie-up in place | ✅ |

| Maintenance SOP created | ✅ |

Frequently Asked Questions About Sludge Dewatering

1. What is sludge dewatering?

Sludge dewatering is the process of removing water from wastewater sludge to reduce its volume and weight. It produces a semi-solid material called “sludge cake,” which is easier and more cost-effective to transport, dispose of, or reuse.

2. Why is sludge dewatering important?

Dewatering reduces sludge volume by up to 80%, cutting transport and disposal costs significantly. It also helps meet environmental regulations and enables sludge reuse in applications like composting or fuel in cement kilns.

3. What equipment is used for sludge dewatering?

Common equipment includes:

- Filter press

- Belt filter press

- Decanter centrifuge

- Screw press

- Paddle dryer (for post-dewatering drying)

Each system is chosen based on sludge type, volume, and dryness goals.

4. What is the typical moisture content after dewatering?

Mechanical dewatering methods can reduce moisture content to 60–75%. If thermal dryers like paddle dryers are used, final moisture levels can drop below 10–15%.

5. Can dewatered sludge be reused?

Yes. Depending on its composition, dewatered sludge can be reused:

- As fuel in industrial boilers or cement kilns

- As soil conditioner (if biologically stable and non-toxic)

- In composting and land applications (subject to approval)

6. How much does a sludge dewatering system cost?

Costs vary based on capacity and technology.

- Small screw press systems (10–50 KLD): ₹5–10 lakhs

- Filter presses or belt presses: ₹15–50 lakhs

- Paddle dryers: ₹40 lakhs and above (based on size)

Operational costs include chemicals, energy, maintenance, and labor.

7. How often should sludge be dewatered?

Frequency depends on sludge generation rates.

- Small plants may dewater once or twice a week

- Medium-to-large facilities typically run dewatering systems daily

Real-time monitoring and sludge holding capacity help optimize schedules.

Conclusion: Sludge Dewatering Is Not Just a Process—It’s a Strategy

In wastewater treatment, managing sludge is often the most overlooked yet most expensive and compliance-critical task. But as we’ve seen, effective sludge dewatering transforms that challenge into a manageable, measurable, and even profitable part of your operation.

Whether you’re working in municipal treatment, industrial effluent processing, or small-scale STPs, dewatering offers more than volume reduction—it brings:

- Operational cost savings

- Regulatory peace of mind

- Opportunities for reuse and resource recovery

From basic filter presses to advanced paddle dryers, there’s a solution for every scale and budget. And when planned thoughtfully—with proper sludge testing, automation, chemical dosing, and disposal strategy—it becomes a streamlined part of your wastewater lifecycle.

More importantly, it helps you align with global environmental goals, reduce landfill dependency, and protect groundwater quality.

Need Help Choosing or Upgrading Your Sludge Dewatering System?

Whether you’re:

- Planning your first sludge handling setup,

- Dealing with high transport costs,

- Facing compliance issues with moisture levels, or

- Exploring sludge-to-energy opportunities…

You don’t have to figure it all out alone.

Reach out to team at AS Engineers—India’s trusted experts in paddle dryers, sludge drying, and zero liquid discharge integration.

Contact today for a personalized consultation or a plant audit.