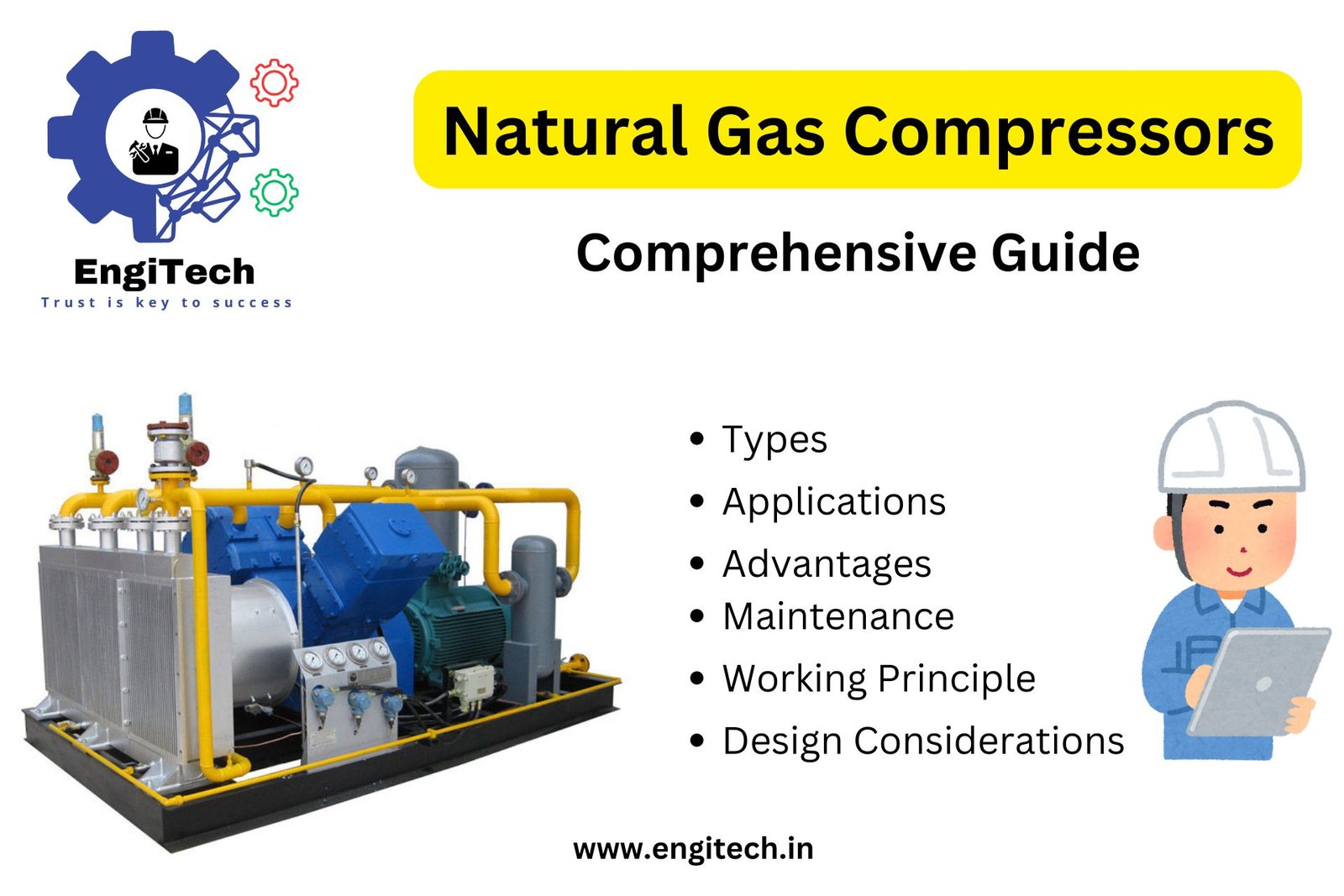

Natural Gas Compressors: A Comprehensive Guide for Knowledge Seekers, Students, and Professionals

Natural gas compressors play a pivotal role in the natural gas industry, facilitating the efficient transport and processing of this vital energy resource. Whether you’re a student exploring mechanical engineering concepts, a knowledge seeker curious about energy systems, or a professional looking to deepen your expertise, understanding the intricacies of natural gas compressors is essential. This guide delves into the mechanics, types, applications, and advancements in natural gas compression, offering expert insights to clarify complex concepts and provide practical knowledge.

Table of Contents

Understanding Natural Gas Compressors

Natural gas compressors are mechanical devices designed to increase the pressure of natural gas, enabling its transportation through pipelines and its use in various applications. Compressing natural gas involves reducing its volume, which makes it easier to move large quantities over long distances. The process is crucial in ensuring that natural gas reaches consumers efficiently and economically.

The Importance of Compressing Natural Gas

Compressing natural gas is vital for several reasons:

- Efficient Transportation: By compressing natural gas, its volume is reduced, making it possible to transport larger quantities through pipelines without requiring excessive energy.

- Storage: Compressed natural gas (CNG) is stored in high-pressure containers, allowing for easier handling and transportation, particularly for vehicles and remote areas.

- Safety: Proper compression of natural gas reduces the risk of leaks and explosions, ensuring safer handling and transportation.

Types of Natural Gas Compressors

There are several types of natural gas compressors, each suited for specific applications. Understanding these types is crucial for selecting the right compressor for your needs.

1. Reciprocating Compressors

Reciprocating compressors are widely used in the natural gas industry due to their reliability and efficiency. These compressors use a piston to compress the gas in a cylinder. As the piston moves, it decreases the volume of the gas, increasing its pressure.

Applications:

- Pipeline Transportation: Reciprocating compressors are commonly used in natural gas pipelines to maintain pressure over long distances.

- CNG Stations: These compressors are also used in compressed natural gas (CNG) refueling stations for vehicles.

Advantages:

- High efficiency in compressing natural gas

- Capable of handling high pressures

- Suitable for a wide range of applications

Expert Insight: According to our engineers, reciprocating compressors are often preferred in situations where reliability and high-pressure capabilities are paramount. Their modular design allows for easy maintenance, making them a long-term investment for natural gas facilities.

2. Centrifugal Compressors

Centrifugal compressors use a rotating impeller to impart velocity to the gas, which is then converted into pressure. These compressors are known for their ability to handle large volumes of natural gas with relatively low maintenance requirements.

Applications:

- Large-Scale Natural Gas Processing: Centrifugal compressors are ideal for large-scale processing plants where high volumes of natural gas need to be handled.

- Pipeline Booster Stations: They are also used in booster stations along natural gas pipelines to maintain the required pressure levels.

Advantages:

- Capable of handling large volumes of gas

- Low maintenance and operational costs

- Suitable for continuous operation

Expert Insight: Our engineering team highlights that centrifugal compressors are preferred in large-scale operations where efficiency and minimal downtime are crucial. These compressors offer a lower cost of ownership over time, making them ideal for extensive natural gas processing facilities.

3. Screw Compressors

Screw compressors use two intermeshing screws to compress the natural gas. These compressors are known for their reliability and ability to handle a variety of gas compositions.

Applications:

- Industrial Applications: Screw compressors are often used in industrial settings where natural gas is used as a fuel or feedstock.

- Gas Gathering Systems: They are also utilized in gas gathering systems to collect and compress gas from multiple sources.

Advantages:

- High reliability and durability

- Capable of handling wet gas and varying gas compositions

- Suitable for continuous and intermittent operation

Expert Insight: Our experts note that screw compressors are versatile and can handle the challenges of varying gas compositions, making them a reliable choice for industrial applications. Their robust design ensures consistent performance even in demanding conditions.

Key Components of Natural Gas Compressors

Understanding the key components of natural gas compressors is essential for those looking to deepen their knowledge or work with these systems.

1. Compressor Cylinder

The cylinder is where the actual compression of natural gas takes place. In reciprocating compressors, the piston moves within the cylinder to compress the gas.

2. Piston

The piston is a moving component that compresses the gas by reducing the volume within the cylinder. Its movement is driven by a crankshaft.

3. Crankshaft

The crankshaft converts rotational motion into the linear motion of the piston. It is a critical component in reciprocating compressors.

4. Valves

Valves control the flow of natural gas into and out of the compressor cylinder. They ensure that gas flows in the correct direction during the compression process.

5. Cooling System

Compressing natural gas generates heat, so a cooling system is essential to maintain the compressor’s efficiency and prevent overheating.

Maintenance and Troubleshooting of Natural Gas Compressors

Proper maintenance of natural gas compressors is crucial to ensure their longevity and efficient operation. Here are some common maintenance practices and troubleshooting tips:

1. Regular Inspection

Conducting regular inspections of key components, such as the piston, cylinder, and valves, can help identify potential issues before they lead to costly breakdowns.

2. Lubrication

Ensuring that all moving parts are adequately lubricated reduces wear and tear, extending the life of the compressor.

3. Cooling System Maintenance

Regularly checking and maintaining the cooling system is essential to prevent overheating, which can lead to compressor failure.

4. Vibration Monitoring

Excessive vibration can indicate underlying issues with the compressor. Monitoring vibration levels can help identify problems early and prevent major failures.

Expert Insight: Our engineers recommend a proactive maintenance approach, emphasizing the importance of regular inspections and the use of high-quality lubricants. They also suggest implementing a vibration monitoring system to detect and address issues before they escalate.

Advances in Natural Gas Compression Technology

The natural gas industry is constantly evolving, and so is the technology behind natural gas compressors. Here are some of the latest advancements:

1. Digital Monitoring Systems

Modern compressors are equipped with digital monitoring systems that provide real-time data on performance, efficiency, and potential issues. These systems enable predictive maintenance, reducing downtime and operational costs.

2. Energy Efficiency Improvements

Newer compressor models are designed to be more energy-efficient, reducing the environmental impact and operational costs associated with natural gas compression.

3. Noise Reduction Technologies

Advancements in noise reduction technologies have made modern compressors quieter, improving the working environment in natural gas facilities.

Expert Insight: Our engineers are excited about the integration of digital monitoring systems in natural gas compressors. These systems allow for more precise control and maintenance, leading to significant improvements in efficiency and reliability.

Environmental Impact and Safety Considerations

The compression of natural gas has environmental and safety implications that must be carefully managed.

1. Emissions Control

Compressors can produce emissions, including methane, which is a potent greenhouse gas. Modern compressors are equipped with emission control technologies to minimize their environmental impact.

2. Safety Protocols

Working with natural gas compressors requires strict adherence to safety protocols to prevent accidents, including explosions and leaks. Proper training and maintenance are key to ensuring safety.

3. Noise Pollution

Noise pollution from compressors can impact surrounding communities and wildlife. Noise reduction technologies are essential in minimizing this impact.

Expert Insight: Our safety engineers emphasize the importance of regular training and adherence to safety protocols. They also advocate for the use of emission control technologies to reduce the environmental impact of natural gas compression.

Applications of Natural Gas Compressors

Natural gas compressors are used in a wide range of applications, each with specific requirements and challenges.

1. Pipeline Transportation

Natural gas pipelines require compressors to maintain the pressure needed to transport gas over long distances. These compressors are strategically placed along the pipeline to boost pressure as needed.

2. CNG Refueling Stations

Compressed natural gas (CNG) is used as a fuel for vehicles, and CNG refueling stations rely on compressors to fill high-pressure tanks.

3. Industrial Applications

Industries that use natural gas as a feedstock or fuel require compressors to manage the gas’s pressure and volume according to their specific needs.

Expert Insight: Our experts note that the application of natural gas compressors in pipelines is one of the most critical aspects of the natural gas supply chain. Proper compressor selection and maintenance are vital to ensuring the continuous and efficient flow of gas to consumers.

Selecting the Right Natural Gas Compressor

Choosing the right natural gas compressor depends on several factors, including the specific application, gas composition, and required pressure levels. Here are some considerations:

1. Application Requirements

Determine whether the compressor will be used for pipeline transportation, industrial applications, or CNG refueling, as this will influence the type of compressor needed.

2. Gas Composition

The presence of impurities or varying gas compositions can affect compressor performance. It’s essential to select a compressor that can handle the specific gas composition of your application.

3. Pressure and Volume Needs

Consider the required pressure and volume of natural gas that the compressor needs to handle. This will influence the size and type of compressor.

Expert Insight: Our engineers recommend working closely with a compressor manufacturer or consultant to ensure that the selected compressor meets all application-specific requirements. This will help avoid issues related to performance and reliability.

Future Trends in Natural Gas Compression

The future of natural gas compression is likely to be shaped by several emerging trends:

1. Integration with Renewable Energy

As the energy industry moves towards renewable sources, natural gas compressors may increasingly be integrated with renewable energy systems to enhance efficiency and reduce environmental impact.

2. Advanced Materials

The development of advanced materials that can withstand higher pressures and temperatures will lead to more durable and efficient compressors.

3. Automation and AI

Automation and artificial intelligence (AI) are expected to play a significant role in the future of natural gas compression, enabling more precise control and reducing the need for manual intervention.

Expert Insight: Our engineers are closely watching the integration of AI in natural gas compression. They believe that AI will revolutionize the industry by enabling smarter, more efficient operations with minimal human oversight.

FAQs Related to Natural Gas Compressors:

1. What is a natural gas compressor?

A natural gas compressor is a mechanical device that increases the pressure of natural gas by reducing its volume, making it easier to transport through pipelines or store in containers.

2. How does a natural gas compressor work?

A natural gas compressor works by reducing the volume of the gas, thereby increasing its pressure. The process can be achieved using different types of compressors, such as reciprocating, centrifugal, and screw compressors, each with its own method of compressing the gas.

3. What are the different types of natural gas compressors?

The main types of natural gas compressors include reciprocating compressors, centrifugal compressors, and screw compressors. Each type has specific applications and benefits depending on the required pressure, volume, and gas composition.

4. Why is natural gas compressed?

Natural gas is compressed to reduce its volume, making it easier and more cost-effective to transport through pipelines, store in containers, and use in various applications such as fueling vehicles or industrial processes.

5. What is the difference between CNG and LNG in terms of compression?

Compressed Natural Gas (CNG) is natural gas stored at high pressure, typically used as fuel for vehicles, while Liquefied Natural Gas (LNG) is natural gas that has been cooled to a liquid state for ease of storage and transport over long distances.

6. How often should a natural gas compressor be maintained?

The maintenance frequency of a natural gas compressor depends on its type, usage, and operating conditions. Regular inspections, lubrication, and monitoring of key components are recommended to ensure optimal performance and prevent breakdowns.

7. What are the safety concerns associated with natural gas compressors?

Safety concerns with natural gas compressors include the risk of leaks, explosions, and fires. Proper maintenance, adherence to safety protocols, and the use of emission control technologies are essential to mitigate these risks.

8. How do I choose the right natural gas compressor for my application?

Choosing the right natural gas compressor involves considering factors such as the required pressure, volume, gas composition, and specific application needs. Consulting with a compressor manufacturer or expert is recommended to make the best choice.

9. What advancements are being made in natural gas compression technology?

Advancements in natural gas compression technology include the development of digital monitoring systems, energy-efficient designs, noise reduction technologies, and the integration of AI for more precise control and predictive maintenance.

10. What is the environmental impact of natural gas compression?

The environmental impact of natural gas compression includes emissions of greenhouse gases like methane and noise pollution. Modern compressors are equipped with emission control technologies and noise reduction features to minimize their environmental footprint.

These FAQs cover a wide range of queries that are commonly searched and asked by individuals interested in natural gas compressors. They are written to provide clear and concise answers to help users understand the fundamentals and advanced aspects of natural gas compression.

Conclusion

Natural gas compressors are a critical component of the natural gas industry, ensuring the efficient transport and processing of this essential resource. Understanding the types, applications, and maintenance of these compressors is crucial for anyone involved in the energy sector. By staying informed about the latest advancements and best practices, you can ensure that your natural gas compression systems operate efficiently and safely.

From EngiTech Team

At EngiTech, we are your ultimate resource for cutting-edge insights and expert knowledge in industrial mechanical engineering. Specializing in industrial dryers, blowers, and a wide array of engineering equipment, our platform empowers professionals, students, and enthusiasts alike with in-depth content that drives innovation and excellence. Whether you’re looking to optimize your processes or stay ahead in the industry, EngiTech delivers the expertise and tools you need to succeed. Explore our comprehensive guides, stay informed on the latest trends, and join a community dedicated to engineering brilliance.