Metallurgical Engineering: Shaping the Future of Materials

Introduction to Metallurgical Engineering

Metallurgical engineering stands at the intersection of materials science and engineering. This field focuses on the study of metals and their properties, the extraction of metals from ores, and the development of new materials and processes to improve metal products. From the steel beams in skyscrapers to the intricate components in smartphones, metallurgical engineers play a crucial role in shaping our world.

The Role of Metallurgical Engineers

Metallurgical engineers work in various industries, including mining, manufacturing, aerospace, automotive, and electronics. They ensure that metals are produced efficiently, safely, and sustainably. They also develop new alloys and materials with improved properties for specific applications.

Real-Life Example: In the aerospace industry, metallurgical engineers develop lightweight and strong alloys for aircraft components. These materials must withstand extreme conditions, such as high temperatures and pressures, while maintaining their integrity. Thanks to metallurgical engineering, modern aircraft are safer, more efficient, and capable of longer flights.

Key Areas of Metallurgical Engineering

- Physical Metallurgy: Physical metallurgy focuses on the structure and properties of metals. Metallurgical engineers in this field study how different processes, such as heat treatment and alloying, affect the mechanical, thermal, and electrical properties of metals.

- Extractive Metallurgy: Extractive metallurgy involves extracting metals from their ores and refining them. This process includes pyrometallurgy (high-temperature processes), hydrometallurgy (aqueous processes), and electrometallurgy (electrochemical processes).

- Mineral Processing: Mineral processing involves separating valuable minerals from waste material in ores. This field ensures that the extraction of metals is efficient and cost-effective, minimizing environmental impact.

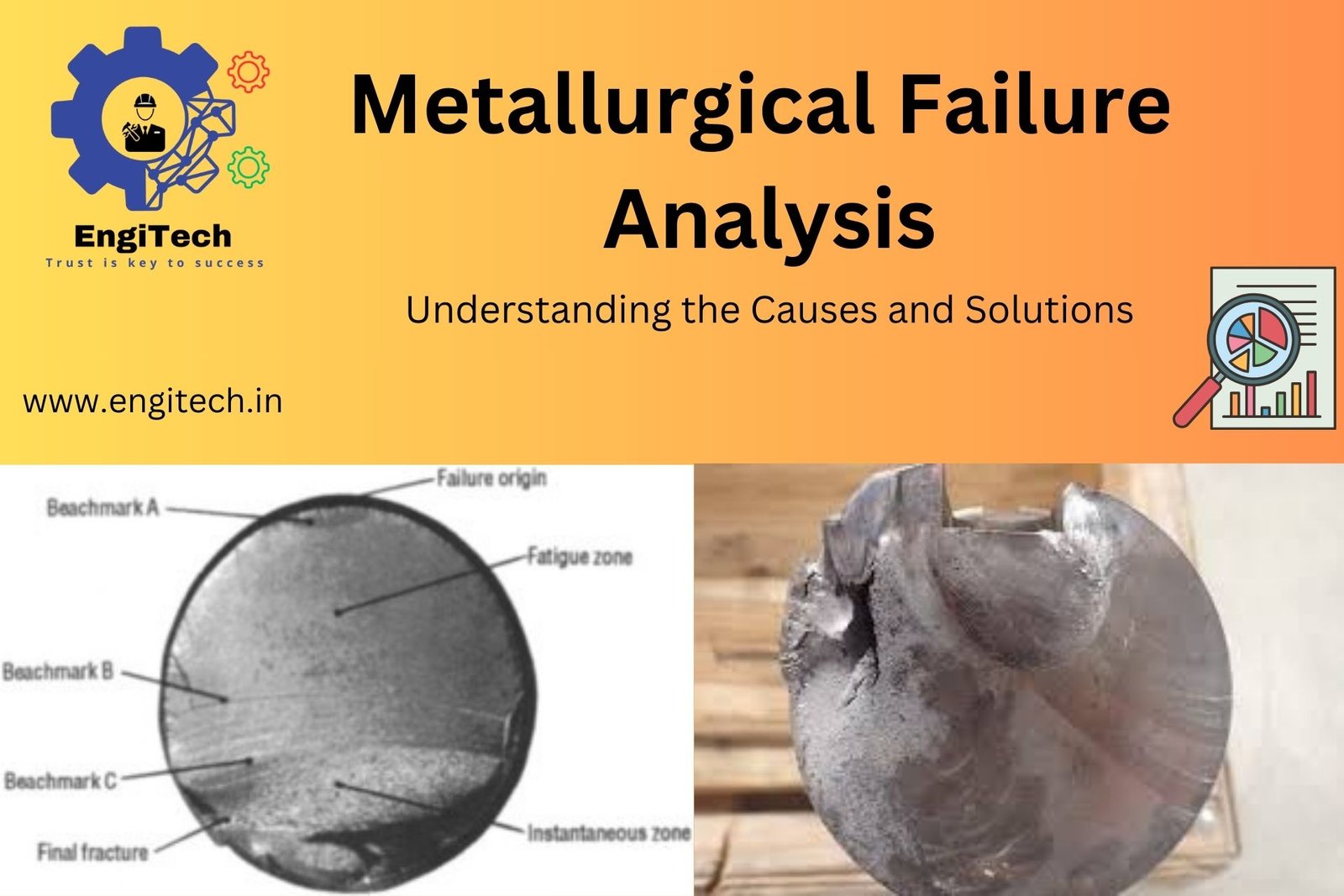

- Mechanical Metallurgy: Mechanical metallurgy focuses on the behavior of metals under mechanical forces. Engineers in this field study deformation, fracture, and fatigue to design materials and components that can withstand mechanical stress.

Real-World Applications of Metallurgical Engineering

1. Automotive Industry: Metallurgical engineers develop advanced high-strength steels and lightweight aluminum alloys to improve fuel efficiency and safety in vehicles. For instance, the development of high-strength, low-alloy (HSLA) steel has allowed automakers to create lighter car frames without compromising safety.

2. Electronics: In the electronics industry, metallurgical engineers create materials with excellent electrical conductivity and thermal stability. Copper and aluminum are commonly used in wiring and circuit boards, but engineers continuously seek ways to improve these materials for better performance and durability.

3. Renewable Energy: Metallurgical engineers contribute to the renewable energy sector by developing materials for wind turbines, solar panels, and energy storage systems. For example, they design corrosion-resistant materials for offshore wind turbines, ensuring long-term reliability in harsh marine environments.

4. Biomedical Engineering: In the biomedical field, metallurgical engineers develop biocompatible materials for implants and medical devices. Titanium alloys are widely used for hip and knee replacements due to their strength, light weight, and compatibility with the human body.

Challenges in Metallurgical Engineering

Metallurgical engineers face several challenges as they strive to develop new materials and processes:

1. Environmental Impact: Mining and metal extraction processes can have significant environmental impacts. Engineers must develop sustainable methods to reduce waste, minimize energy consumption, and mitigate pollution.

2. Material Performance: As industries demand more from materials, metallurgical engineers must design alloys that can perform under extreme conditions, such as high temperatures, corrosive environments, and mechanical stress.

3. Cost Efficiency: Balancing performance and cost is a constant challenge. Engineers must find ways to produce high-performance materials at a reasonable cost to make them viable for commercial use.

4. Recycling and Sustainability: With increasing emphasis on sustainability, metallurgical engineers are tasked with developing efficient recycling processes and designing materials that are easier to recycle. This effort helps conserve natural resources and reduce the environmental footprint of metal production.

Future Trends in Metallurgical Engineering

1. Advanced Manufacturing: The integration of advanced manufacturing techniques, such as additive manufacturing (3D printing) and digital twin technology, is revolutionizing metallurgical engineering. These technologies enable the production of complex metal components with enhanced properties and reduced waste.

2. Smart Materials: Smart materials, which can respond to environmental changes, are becoming increasingly important. Metallurgical engineers are developing alloys that can change shape, heal themselves, or alter their properties in response to external stimuli.

3. Nanotechnology: Nanotechnology is opening new frontiers in metallurgical engineering. Engineers are exploring nanoscale materials with unique properties, such as increased strength, enhanced conductivity, and improved corrosion resistance.

4. Sustainable Practices: The push for sustainability is driving innovation in metallurgical engineering. Engineers are developing greener extraction methods, designing materials for longer lifespans, and improving recycling technologies to create a more sustainable metal industry.

Conclusion

Metallurgical engineering plays a vital role in advancing technology and improving our quality of life. By understanding the properties and behavior of metals, metallurgical engineers develop materials and processes that drive innovation across multiple industries. As the world continues to face new challenges, the field of metallurgical engineering will remain at the forefront of creating sustainable, high-performance materials for the future.

For more in-depth articles and resources on metallurgical engineering and other industrial technologies, visit EngiTech.in. Stay updated on the latest advancements and applications in the industry!