Hydrocyclone filters have revolutionized industrial separation processes by harnessing the power of centrifugal forces to separate solids from liquids. Whether you’re in mining, oil and gas, wastewater treatment, or food processing, understanding the design and operation of a hydrocyclone filter can significantly optimize your filtration systems and reduce maintenance costs. In this ultimate guide, we will explore what a hydrocyclone filter is, how it works, its engineering principles, real-world applications, advantages, limitations, and best practices for maintenance.

Table of Contents

Introduction: The Need for Efficient Filtration

In many industrial processes, handling large volumes of liquid contaminated with solids can lead to operational inefficiencies and increased maintenance costs. Traditional filtration methods often require frequent cleaning, suffer from clogging issues, or have high operational expenses. Enter the hydrocyclone filter—a cost-effective, reliable solution with no moving parts, minimal energy requirements, and exceptional separation performance.

By integrating hydrocyclone filters into your system, you not only protect downstream equipment from abrasive wear but also reduce downtime and improve product quality. This guide will delve into the inner workings, engineering design, and maintenance strategies that ensure your filtration process is optimized for both efficiency and longevity.

What Is a Hydrocyclone Filter?

A hydrocyclone filter is a type of cyclonic separator that uses centrifugal forces to separate solid particles from liquids. Unlike traditional filters that rely on physical barrier media (screens, cartridges, or membranes), a hydrocyclone filter operates without any moving parts. This simplicity leads to higher reliability, reduced maintenance needs, and lower operating costs.

Key Characteristics

- Centrifugal Separation: Uses the rotational movement of fluid to create centrifugal forces that separate particles.

- No Moving Parts: The absence of mechanical components minimizes wear and tear.

- Compact Design: Fits into tight spaces and can be easily integrated as a pre-treatment stage before finer filtration.

- Versatile: Applicable in various industries including mining, oil and gas, chemical processing, and food & beverage.

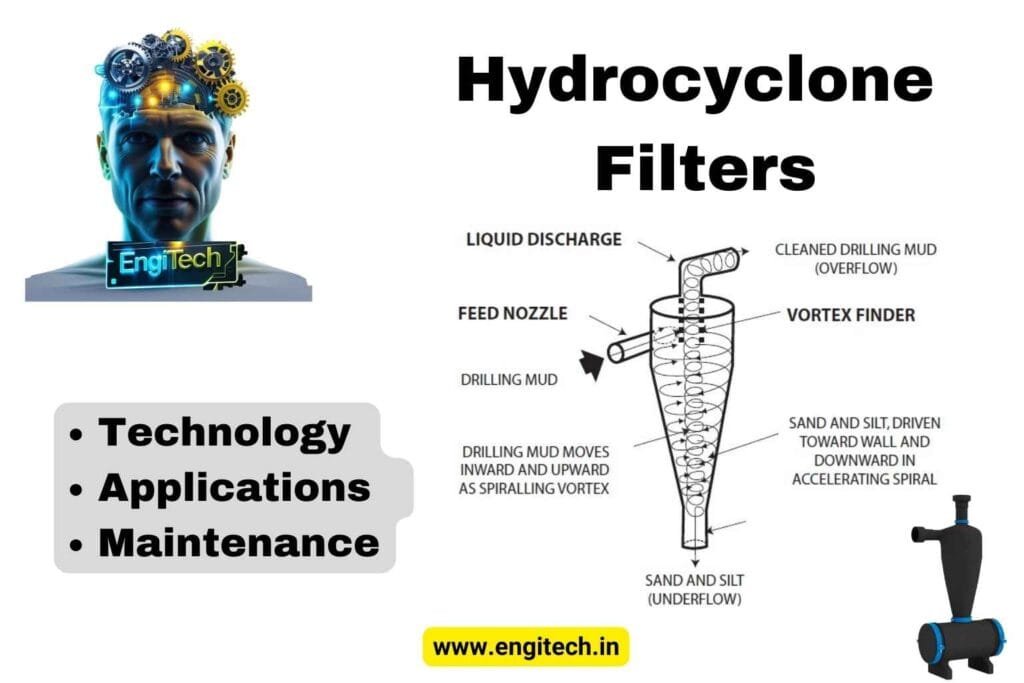

How Does a Hydrocyclone Filter Work?

The operation of a hydrocyclone filter is based on the principles of centrifugal force and fluid dynamics. Here’s a step-by-step breakdown of the process:

1. Tangential Feed Injection

Contaminated liquid enters the hydrocyclone tangentially through an inlet. This off-center entry induces a swirling motion, causing the liquid to spin rapidly inside the chamber.

2. Formation of a Vortex

As the fluid rotates, a strong vortex is created. Due to the centrifugal force generated by this vortex, heavier particles are forced outward against the cyclone wall.

3. Separation and Discharge

Within the cyclone, two distinct flow paths develop:

- Underflow: Heavier, larger particles spiral downward along the wall and are discharged through the narrow apex (bottom outlet).

- Overflow: The lighter, clean liquid forms an inner spiral that moves upward and exits through the top outlet via a vortex finder.

4. No Moving Parts, No Clogging

Because separation is achieved through fluid dynamics rather than a physical barrier, hydrocyclone filters are less susceptible to clogging and require minimal cleaning.

Design and Engineering Principles

The efficiency of a hydrocyclone filter is largely dependent on its design and operating parameters. Here are the most critical aspects:

Key Components

- Inlet Nozzle: Introduces the fluid tangentially to initiate the vortex.

- Cylindrical Section: Provides the initial rotational motion.

- Conical Section: The tapering shape accelerates the flow, increasing centrifugal force for better separation.

- Vortex Finder: Directs the cleaned liquid upward to exit the unit.

- Underflow Outlet (Apex): Discharges the separated solids.

Critical Design Parameters

- Feed Pressure: A higher feed pressure results in a stronger vortex and better separation; however, excessive pressure may lead to erosion. Typical working pressures range from 3 to 8 psi (head loss) with maximum recommended working pressure around 120 psi.

- Geometry: The diameter of the cyclone, the length of the cone, and the ratio between the vortex finder and apex all influence performance.

- Flow Rate: The operating flow rate must be within the designed range to maintain optimal separation efficiency.

Engineering Insights

- Centrifugal Force Calculations: The separation efficiency is related to the square of the tangential velocity. Precise engineering calculations ensure that particles above a certain size (cut-off point) are efficiently removed.

- Material Selection: Hydrocyclones are manufactured using corrosion-resistant materials like stainless steel or specialized polymers, ensuring durability even in aggressive environments.

Key Applications Across Industries

Hydrocyclone filters are employed in a wide range of industrial applications thanks to their robust design and cost-effectiveness. Here’s how they are used in different sectors:

Mining and Minerals Processing

- Ore Classification: Hydrocyclones separate valuable ore particles from slurry, increasing the efficiency of subsequent processing steps.

- Dewatering: They concentrate slurries by removing excess water, thus lowering transportation and processing costs.

Oil and Gas

- Produced Water Treatment: Hydrocyclones remove sand and other particulate matter from produced water, ensuring that the water meets environmental discharge standards.

- Drilling Fluid Reclamation: They separate drill cuttings from drilling fluids, enabling fluid recycling and reducing waste.

Wastewater Treatment

- Pre-Treatment: Acting as a pre-filter, hydrocyclones reduce the load on downstream membrane systems by removing larger particles.

- Effluent Quality Improvement: Enhanced separation leads to cleaner effluent that is easier to treat further or safely discharge.

Food and Beverage Processing

- Juice Clarification: Hydrocyclones are used to remove suspended solids from fruit juices, resulting in a clearer and more appealing product.

- Starch Recovery: In potato and corn processing, they efficiently separate starch from water, maximizing yield and reducing waste.

Chemical Processing

- Catalyst Recovery: They are used to recover catalyst particles from reaction mixtures, allowing for catalyst reuse.

- Solution Clarification: Hydrocyclones clarify process streams by removing unwanted precipitates, ensuring product purity.

Other Industries

- Seawater Filtration: Protect equipment from corrosion by removing sand and silt from seawater.

- Microplastic Separation: Emerging applications include the removal of microplastics from wastewater, contributing to environmental sustainability.

Advantages and Limitations

Advantages

- Low Maintenance: With no moving parts, hydrocyclone filters require minimal maintenance and are less prone to clogging.

- Cost-Effective: Their simple design translates to lower capital and operating costs compared to traditional filtration systems.

- High Throughput: Capable of handling large volumes of slurry with consistent performance.

- Versatility: Suitable for a variety of applications from pre-treatment to final separation across multiple industries.

- Robust Performance: Efficiently separates particles across a broad range of sizes when designed within the appropriate operating parameters.

Limitations

- Design Sensitivity: Performance can be compromised if the operating conditions (flow rate, pressure, particle size) deviate from the design specifications.

- Wear and Erosion: High feed pressures, while increasing separation efficiency, may lead to accelerated wear on internal surfaces.

- Limited Fine Particle Separation: Extremely fine or emulsified particles may not be effectively separated and could require additional treatment stages.

- Capacity Constraints: Large-diameter hydrocyclones might not generate sufficient centrifugal force for optimal separation, limiting their application in certain high-volume processes.

Maintenance, Troubleshooting, and Best Practices

Proper maintenance is key to ensuring that your hydrocyclone filter operates efficiently over the long term. Below are some best practices and troubleshooting tips:

Regular Inspections

- Visual Check: Regularly inspect the exterior and interior (if accessible) of the hydrocyclone for signs of erosion, wear, or blockage.

- Pressure Monitoring: Keep an eye on pressure differentials. A drop below 3 psi can indicate suboptimal separation, whereas pressures above 8 psi may signal excessive wear.

- Flow Rate Verification: Ensure that the flow rate is within the specified range; deviations could affect separation efficiency.

Routine Cleaning

- Sedimentation Tank Flushing: Hydrocyclones often incorporate a sedimentation or collection chamber for separated solids. Schedule regular manual or automated flushing to remove accumulated debris.

- Preventive Cleaning Cycles: In systems integrated with automatic backflush options, adjust the cleaning cycle based on operational parameters to maintain efficiency.

Component Maintenance

- Replace Wear Parts: Rubber inserts or protective coatings inside the cyclone may need periodic replacement, especially in abrasive applications.

- Greasing and Lubrication: For hydrocyclones that include any sealing components or threaded connections, annual greasing can prevent corrosion and maintain performance.

Troubleshooting Common Issues

- Reduced Separation Efficiency: Check for improper feed pressure, incorrect flow rates, or blockage in the sedimentation chamber.

- Excessive Wear: If internal surfaces show signs of accelerated erosion, consider reducing feed pressure or installing wear-resistant liners.

- Clogging or Blockages: Even though hydrocyclones are less prone to clogging, solid build-up in the collection chamber can occur. Regular cleaning and inspection help prevent operational disruptions.

Best Practices for Optimal Performance

- Monitor Operational Data: Utilize sensors and data logging to continuously monitor flow rates, pressures, and separation efficiency.

- Implement Scheduled Maintenance: Develop a maintenance schedule that fits your operating conditions and strictly adhere to it.

- Consult with Experts: For complex systems or unique applications, working with experienced engineers or manufacturers can help tailor the hydrocyclone design to your specific needs.

Future Trends and Innovations in Hydrocyclone Filters

The hydrocyclone filter technology continues to evolve, driven by advances in materials science, computational fluid dynamics, and process control systems. Here are some emerging trends:

Material Innovations

- Advanced Wear-Resistant Coatings: Research into coatings that reduce erosion can extend the lifespan of hydrocyclones, even under harsh operating conditions.

- Composite Materials: The development of high-strength, corrosion-resistant composites may reduce maintenance needs and improve durability.

Digital Integration

- Smart Sensors: Integration of IoT sensors allows for real-time monitoring of operational parameters, enabling predictive maintenance and process optimization.

- Data Analytics: Leveraging big data and machine learning can refine the design parameters for optimal separation efficiency based on historical performance.

Process Optimization

- Hybrid Separation Systems: Combining hydrocyclones with other filtration or separation technologies can achieve superior performance, particularly for challenging feeds with emulsified particles.

- Energy Efficiency Improvements: Innovations in pump design and system integration can lower energy consumption while maintaining high separation performance.

Environmental Impact

- Microplastic Removal: With growing environmental concerns, hydrocyclones are being optimized to remove microplastics from wastewater, contributing to cleaner water systems worldwide.

- Sustainable Design: The push toward green engineering is driving innovations that reduce waste, lower energy use, and enhance the recyclability of system components.

Conclusion

Hydrocyclone filters represent a critical technology for efficient, reliable, and cost-effective solid–liquid separation across a myriad of industries. By understanding the fundamental principles, design parameters, and maintenance requirements, you can optimize your process systems and achieve significant operational benefits—from reduced downtime and lower maintenance costs to improved product quality and environmental compliance.

Whether you are looking to upgrade your existing filtration system or design a new one from the ground up, investing in high-quality hydrocyclone filters and implementing a rigorous maintenance strategy will pay dividends in efficiency and long-term performance.

Ready to transform your filtration process? Contact us today for a personalized consultation and discover how our hydrocyclone filters can elevate your operations to the next level.

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.