Paddle Dryer: Your Complete Guide to Selection, Performance & Cost

So, you’re looking into getting a paddle dryer for your operation? It’s a big decision, and honestly, there’s a lot to think about. We see a lot of folks jump in without really knowing what they’re getting into, and that can lead to some headaches down the road. This guide is here to break down what you need to know, straight from people who deal with this stuff every day. We’ll cover how these machines work, what to look for when you’re buying, and how to make sure you’re getting the most out of your investment. Think of it as your no-nonsense guide to picking the right paddle dryer.

Table of Contents

Key Takeaways

- Paddle dryers use indirect heating and mixing paddles to efficiently remove moisture from various materials, from sludge to powders.

- When selecting a paddle dryer, consider your material’s specific properties, how much you need to process, and the best heating method for your setup.

- Look beyond the initial price; evaluate the total cost of ownership, including energy use and maintenance, for long-term savings.

- Many industries, including wastewater treatment, pharmaceuticals, food, and chemicals, benefit greatly from the consistent and controlled drying a paddle dryer provides.

- Choosing a manufacturer with proven expertise, custom design capabilities, and strong after-sales support is vital for a successful and reliable paddle dryer investment.

Understanding Paddle Dryer Technology

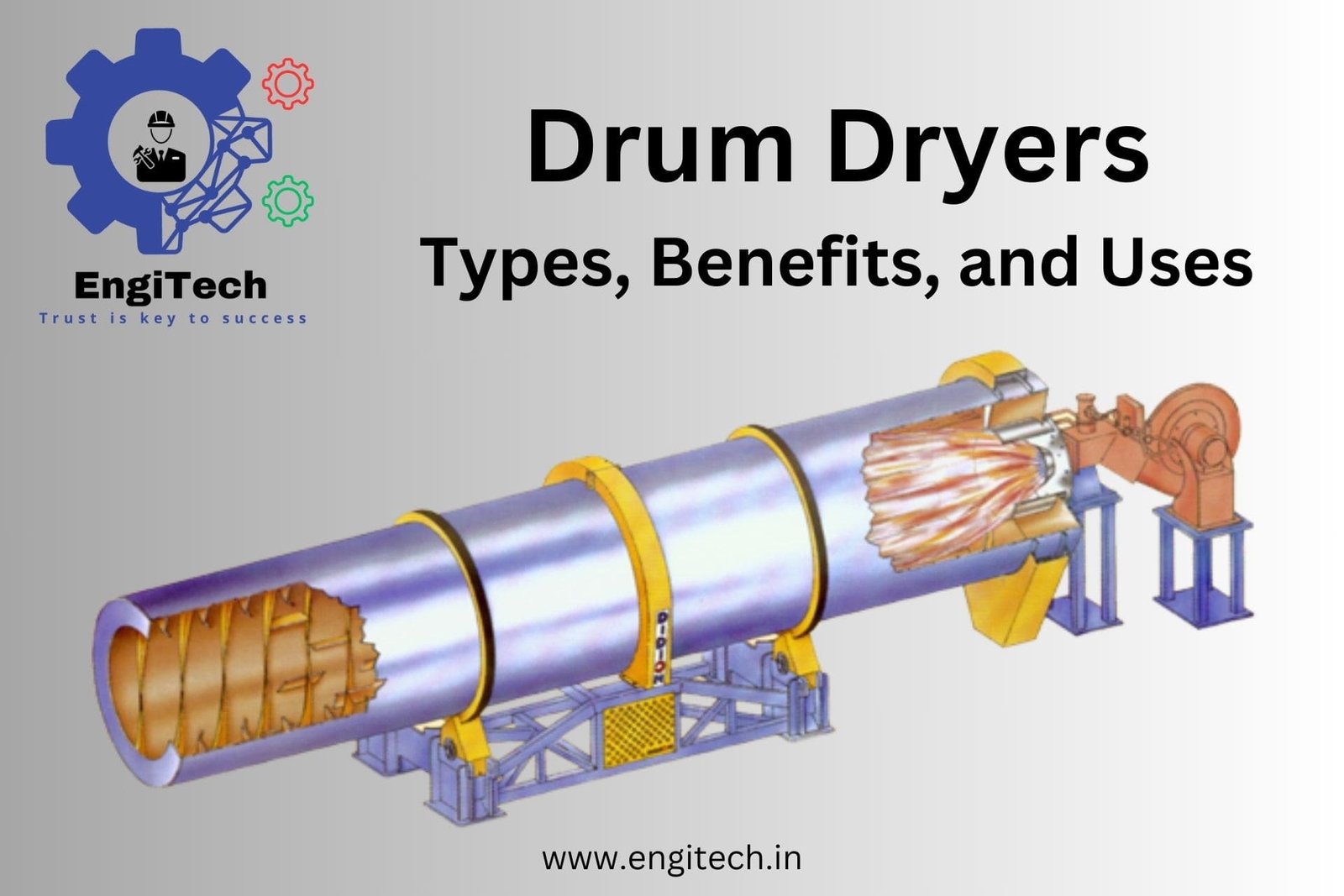

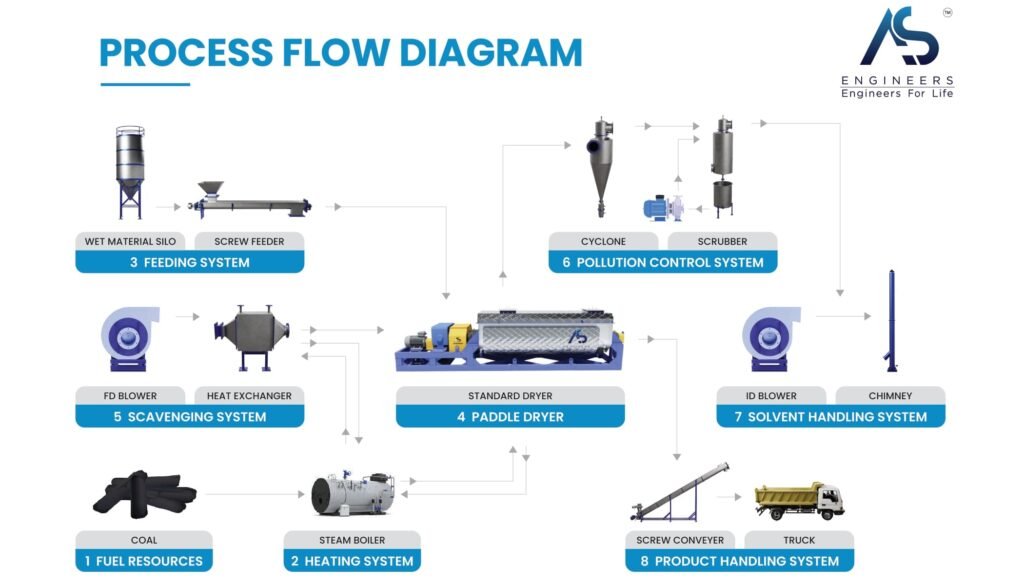

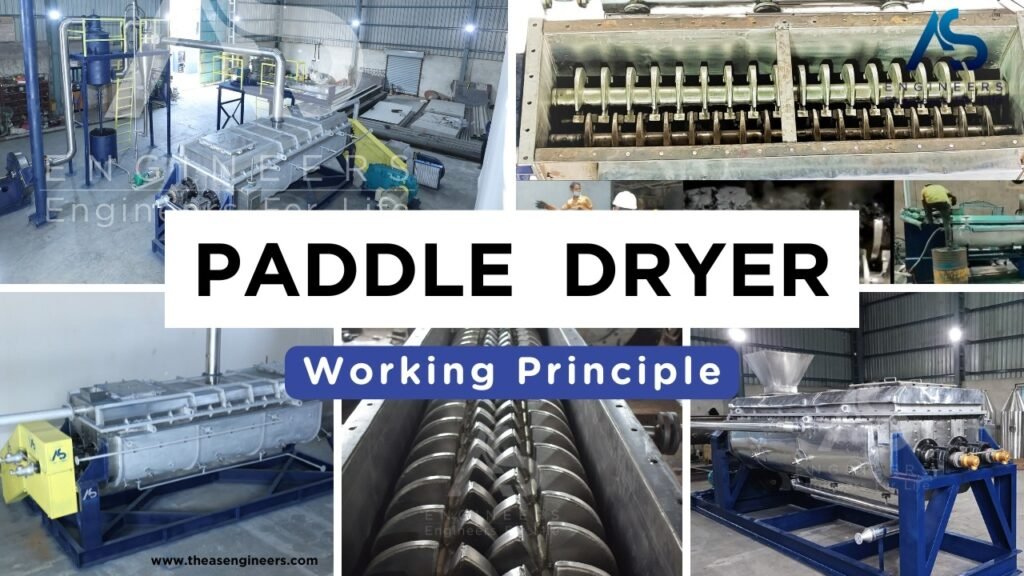

So, what exactly is a paddle dryer? Think of it as a specialized piece of equipment designed to take wet stuff and make it dry, efficiently. It’s a type of indirect heat dryer, meaning the heat doesn’t come into direct contact with the material being dried. Instead, heat is transferred through the walls of the dryer and, importantly, through hollow paddles that spin around a central shaft.

What Is a Paddle Dryer?

At its core, a paddle dryer is a horizontal mixing dryer. It uses a series of paddles, often shaped like wedges, attached to a rotating shaft. These paddles are hollow and are heated internally by a medium like steam, hot oil, or hot water. As the shaft turns, the paddles move through the wet material, mixing it thoroughly. This constant agitation ensures that all parts of the material come into contact with the heated surfaces, speeding up the drying process. They’re pretty versatile, handling everything from sticky sludges to granular powders.

How Does It Work?

The process is pretty straightforward. First, the wet material is fed into the dryer. Then, the magic happens: the hollow paddles and the dryer’s jacket get hot. As the shaft rotates, the paddles stir and tumble the material. This action does two main things: it breaks up lumps and ensures maximum contact between the wet material and the heated surfaces. Moisture from the material turns into vapor and is typically removed by a gentle flow of gas or a vacuum system. Finally, the dried product is discharged.

- Feed: Wet material enters the dryer.

- Heating & Mixing: Hollow paddles and the dryer jacket transfer heat while mixing the material.

- Evaporation: Moisture turns into vapor and is removed.

- Discharge: Dry product exits the dryer.

Because the heat source is separate from the material, paddle dryers are great for drying things that might be sensitive to high temperatures or could contaminate if they touched a direct heat source. This makes them a good choice for industries where purity is a big deal.

Consistent Results

One of the big selling points of paddle dryers is their ability to produce consistent results. The design, with its uniform heating and constant mixing, means that every particle of material gets roughly the same amount of drying time. This lack of ‘back-mixing’ or uneven drying helps maintain product quality and predictability. You get a more uniform moisture content across the entire batch, which is pretty important for many industrial processes.

Key Considerations for Paddle Dryer Selection

Picking the right paddle dryer isn’t just about picking a machine; it’s about finding a partner for your production process. You’ve got to think about a few things before you even start looking. Getting this right means your dryer will work well for years, saving you headaches and money.

Define Your Material Characteristics

Every material is different, and that’s the first thing to nail down. What are you actually drying? Think about its starting moisture level – is it a wet sludge or just slightly damp powder? The particle size and shape matter too; fine powders behave differently than coarse granules. How does it flow? Sticky materials can cling to paddles, causing issues. And importantly, is your material sensitive to heat? Some products can break down or change if they get too hot, which means you’ll need a dryer that can operate at lower temperatures, maybe under vacuum.

- Initial Moisture Content: High moisture means more water to remove, potentially needing more heat or time.

- Particle Size & Shape: Affects how well heat transfers and how easily material moves.

- Flowability: Sticky or cohesive materials require specific paddle designs for effective mixing.

- Thermal Sensitivity: Determines the maximum operating temperature and if vacuum drying is necessary.

Estimate Throughput Requirements

How much product do you need to dry, and how quickly? You need to match the dryer’s capacity to your production goals. If you get a dryer that’s too small, you’ll be running it constantly, pushing it to its limits, and still not meeting demand. Too big, and you’re wasting energy and capital on a machine that’s mostly sitting idle. It’s a balancing act.

Accurately calculating your required throughput prevents inefficiencies from either underutilization or system overload. It’s better to have a slightly larger capacity than to constantly struggle with production targets.

Decide on the Heating Medium

How will you heat the dryer? There are a few common options, and each has its pros and cons.

- Steam: It’s often readily available in many plants and heats up quickly.

- Thermal Oil: This gives you very precise temperature control, leading to more uniform heating.

- Hot Water: Good for materials that don’t need very high temperatures.

Your choice here can impact energy costs and how well you can control the drying process.

Consider Energy Efficiency

This is a big one for the long haul. A dryer that uses less energy will save you a lot of money over its lifetime. Look at how well the heat gets into your product. Things like the amount of surface area available for heating, how well heat moves through the materials, and how well the dryer is insulated all play a part. A more efficient machine might cost a bit more upfront, but it usually pays for itself through lower operating expenses.

Evaluating Paddle Dryer Performance and Costs

So, you’re looking at paddle dryers, huh? It’s a big decision, and honestly, it’s not just about the sticker price. You’ve got to think about the whole picture, from what it costs to get it running to how much it’ll cost to keep it humming along for years. It’s easy to get caught up in the initial purchase, but that’s just the start.

Analyze Total Cost of Ownership

When you’re figuring out the total cost, don’t just look at the machine itself. Think about everything that goes into it. This includes the initial price, sure, but also installation, any extra bits you need like special feed systems or vapor treatment, and even the training for your team. Sometimes, a slightly more expensive machine upfront can save you a ton down the road because it’s more efficient or needs less fixing. It’s about the long game, not just the immediate outlay.

Energy Efficiency and Operational Costs

This is a big one. How much power does this thing actually use? A dryer that’s really good at transferring heat means you’re not wasting energy. Look at things like how well the heat gets from the heating medium to your material. Good insulation also plays a part. Lower energy use directly translates to lower bills every month, which really adds up over time. It’s not just about the watts or BTUs; it’s about how effectively the dryer uses them to get the job done.

Maintenance Needs and Reliability

What’s it going to take to keep this thing running smoothly? Some dryers are just plain easier to work on than others. Can you get to the parts that need regular checking or cleaning without a major hassle? And what about spare parts – are they easy to find, or do you have to wait weeks for a special order? A dryer that’s designed with maintenance in mind will spend less time sitting idle, and that means more uptime for your production. You want a machine that’s built tough and designed for easy upkeep.

Here’s a quick look at what to consider:

- Ease of Access: Can your team easily inspect and clean key components?

- Part Availability: Are common wear parts stocked or quickly obtainable?

- Design Simplicity: Does the design avoid overly complex mechanisms that are prone to failure?

- Manufacturer Support: Does the maker offer good service manuals and troubleshooting guides?

Thinking about maintenance early can save you a lot of headaches and unexpected costs later. It’s better to know what you’re getting into before the dryer is even on your factory floor.

Industries Benefiting from Paddle Dryers

Paddle dryers are pretty versatile machines, showing up in a bunch of different industries where getting rid of moisture is a big deal. They’re not just for one type of material either; they can handle everything from sticky sludges to fine powders.

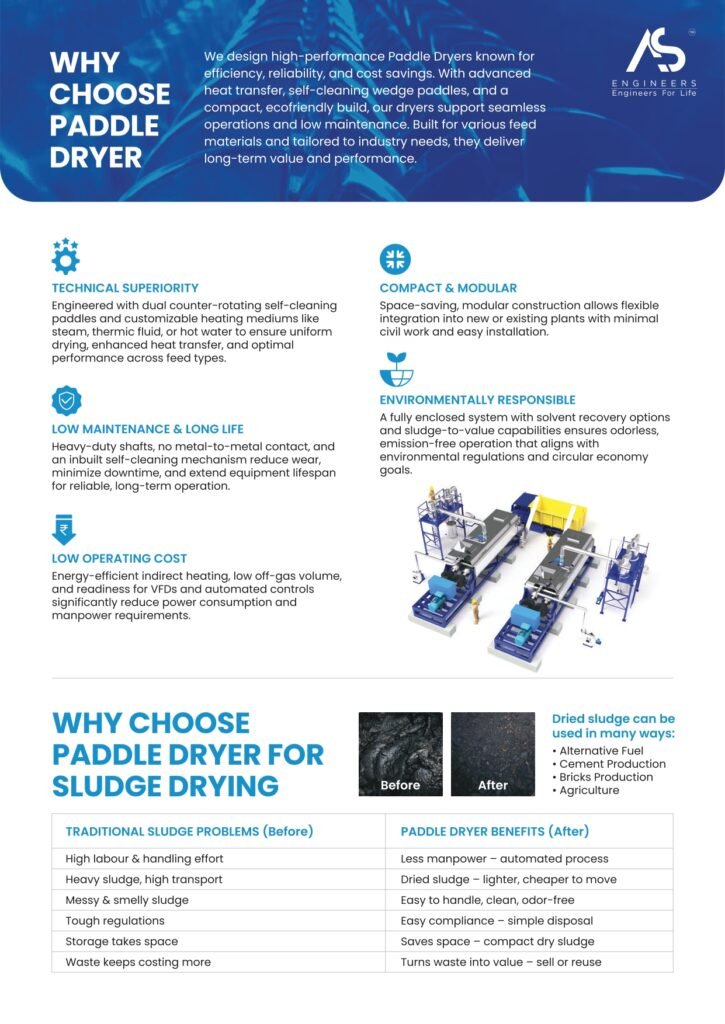

Wastewater Treatment Applications

This is a major area where paddle dryers shine. Think about sewage sludge or industrial wastewater. These materials are often wet and bulky, making them a pain to deal with. A paddle dryer can significantly cut down the volume by removing a lot of the water. This makes disposal easier and cheaper, and sometimes the dried material can even be repurposed. It’s a big win for environmental protection efforts, helping manage waste more effectively. Many water treatment plants rely on these units to process digested sludge and other waste materials, reducing the volume by several times.

Pharmaceutical and Food Processing

In these sectors, product quality is everything. Paddle dryers are good here because they offer controlled drying without damaging sensitive ingredients. They can handle things like active pharmaceutical ingredients (APIs) or food items like milk powders, sugars, and grains. The enclosed nature of the dryer and the gentle mixing mean less contamination risk and a more consistent final product. Plus, their ability to operate under vacuum is a big plus for certain food and pharma applications. Maintaining precise moisture levels is key to product stability and shelf life.

Chemical, Paper, and Metal Industries

Chemical plants use paddle dryers for all sorts of powders and granules, like pigments, dyes, or catalysts. The gas-tight design is a big advantage when dealing with materials that might react with air. In the paper industry, they’re used for drying sludge from the pulping process, which can then be used for energy recovery. For metals, think about drying metal powders or sludges from finishing processes. These dryers can handle materials like lithium or iron powders, and minerals like gypsum. They can even do heating and cooling in the same unit, which is handy for metal processing. You can find more details on their use in various sectors by looking at paddle dryers.

The ability of paddle dryers to handle a wide range of materials, from wet sludges to fine powders, makes them a valuable asset in many industrial processes. Their efficient heat transfer and controlled drying environment contribute to cost savings and improved product quality across different applications.

Troubleshooting Common Paddle Dryer Issues

Even the best equipment can run into snags now and then. Paddle dryers, while robust, can sometimes present challenges that affect output or product quality. Understanding these common issues and how to address them can save you a lot of headaches and keep your operation running smoothly.

Addressing Low Machine Output

When your paddle dryer isn’t producing as much as you expect, it’s usually down to a few key things. First, check if the feed is actually filling the machine to its intended capacity. Running it too empty means less material is being processed. Another common culprit is the speed of the paddles; if they’re rotating too slowly, they won’t mix and move the material effectively. Also, keep an eye on your exhaust system. If vapors are lingering in the dryer because the exhaust isn’t strong enough, it can slow down the drying process. Leaks in the jacket or trough can also let heat escape or allow unwanted air in, impacting performance.

- Ensure the dryer is loaded to its optimal working capacity.

- Increase paddle rotation speed if necessary.

- Inspect and clear any blockages in the exhaust pipe.

- Repair any detected leaks in the dryer’s casing or jacket.

- Verify that the exhaust fan is functioning correctly and moving sufficient vapor.

Resolving High Moisture Content

Getting the moisture level just right is critical. If your product is coming out wetter than it should be, several factors could be at play. The material might not be spending enough time in the dryer – that’s retention time. If you’re feeding too much material at once, or if the initial feed is already very wet, the dryer might struggle to keep up. The heating temperature is also a big one; if it’s too low, the drying just won’t happen effectively.

Sometimes, the simplest solutions are the most overlooked. It’s easy to get caught up in complex diagnostics, but often, a quick check of the basic operating parameters like feed rate and temperature can reveal the issue.

- Increase the material’s residence time within the dryer.

- Reduce the volume of material being fed into the dryer.

- Increase the heating temperature to the recommended setting.

- Adjust the initial moisture content of the feedstock if possible.

Preventing Powder Adhesivity and Paddle Failure

Sticky materials can be a real pain, clinging to the paddles and the dryer walls, which reduces heat transfer and can even cause the paddles to fail if the buildup is severe enough. This often happens when the heating isn’t quite right – either the paddles themselves aren’t getting hot enough, or the overall temperature in the trough is too low. Overloading the system with too much material can also contribute to this stickiness. Paddle failure itself, beyond adhesion, can stem from worn-out parts like rotary joints or motor issues. Regular checks and maintenance are key here. For sticky products, consider a pilot test to dial in the exact operating conditions needed. You can find more information on handling challenging materials at thermal sludge drying systems.

- Monitor and maintain adequate heating of paddles and the trough.

- Reduce the volume of material processed if overloading is suspected.

- Regularly inspect and maintain rotary joints and drive motors.

- Implement a consistent cleaning schedule, especially for sticky materials.

- Ensure proper lubrication of all moving parts to prevent wear.

Choosing a Trusted Paddle Dryer Manufacturer

Picking the right company to build your paddle dryer is a big deal. It’s not just about buying a piece of equipment; it’s about investing in a solution that will impact your production for years to come. You want a manufacturer that really gets what you’re trying to do.

Expertise and Custom Design Approach

When you talk to potential manufacturers, see if they take the time to really understand your specific material. What’s its moisture content like? How does it flow? Is it sensitive to heat? A good manufacturer won’t just offer you a standard model. They’ll ask a lot of questions and might even suggest custom modifications to make sure the dryer works perfectly for your product. This tailored approach is key to getting the most out of your investment. They should be able to explain why they’re recommending certain features based on your material and goals.

Commitment to After-Sales Support

What happens after the dryer is installed? That’s where the real partnership begins. Look for a company that offers solid support. This includes:

- Installation and Commissioning: Making sure the dryer is set up correctly and running smoothly on your site.

- Operator Training: Helping your team understand how to run and maintain the equipment safely and efficiently.

- Maintenance Services: Offering scheduled check-ups or quick help when something goes wrong.

- Troubleshooting Assistance: Being available to help diagnose and fix problems.

Don’t underestimate the importance of ongoing support. A dryer that’s hard to maintain or fix can quickly become a costly headache.

Reliable Spare Parts Availability

Every piece of machinery needs parts replaced eventually. A reliable manufacturer will have a good stock of common spare parts, like paddles, seals, and bearings. Knowing you can get the parts you need quickly means less downtime for your operation. It’s worth asking about their spare parts inventory and how quickly they can ship items if you need something unexpected.

| Component Type | Typical Lead Time | Availability |

|---|---|---|

| Paddles | 2-4 weeks | High |

| Seals | 1-3 weeks | High |

| Bearings | 1-2 weeks | High |

| Drive Components | 3-6 weeks | Medium |

Optimizing Your Paddle Dryer Investment

So, you’ve picked out a paddle dryer, which is great. But just buying the machine is only half the battle, right? Making sure it runs well and keeps running well for years to come is where the real work starts. It’s like buying a car – you need to know how to drive it, maintain it, and maybe even tune it up a bit to get the most out of it.

The Importance of Pilot Testing

Before you commit to a full-scale paddle dryer, seriously think about doing a pilot test. It’s not just a suggestion; it’s a smart move. You get to see how your specific material actually behaves in the dryer. This means you can figure out the best drying times, how much energy it’s really going to use, and what the final product quality will be like. It’s way better to tweak things on a small scale than to find out your big, expensive machine isn’t quite right after it’s already installed. Manufacturers often have pilot units you can use, and it’s worth the investment to get that real-world data.

Integration with Existing Systems

Most of the time, a new paddle dryer isn’t going to be the only piece of equipment in your plant. You need to think about how it’s going to connect with what you already have. Can it easily take material from your current conveyor system? Will its output feed smoothly into your next process step? Sometimes, you might need some custom modifications or extra controls to make everything work together. A good manufacturer will help you figure this out and make sure the integration is as smooth as possible, so you don’t end up with a bottleneck or a system that’s fighting itself.

Long-Term Value and Performance

When you’re looking at the total cost, don’t just focus on the sticker price. Think about the whole picture: how much energy will it use day-to-day? What are the maintenance costs going to be? How often will you need to replace parts? A dryer that’s built well and designed for efficiency might cost a bit more upfront, but it can save you a ton of money over its lifespan. Plus, a reliable machine means less downtime, which is money you don’t lose. It’s all about getting the best performance and value over the long haul, not just the cheapest option today. Keeping up with maintenance, like checking seals and lubricating moving parts, is also key to keeping things running smoothly and preventing bigger problems down the road. It’s the little things that add up to big savings and consistent output.

Wrapping Up Your Paddle Dryer Decision

So, picking the right paddle dryer is a big deal for your operation. It’s not just about getting a machine; it’s about finding a partner that helps you dry things efficiently and reliably. We’ve walked through what makes these dryers tick, how to pick the best one for your specific needs, and what to look for in a manufacturer. Remember to think about your material, how much you need to process, and the long-term costs. Don’t forget about support after you buy, either. Getting this right means smoother operations, better product quality, and ultimately, a healthier bottom line. If you’re still unsure, reaching out to the experts we’ve talked about is a smart next step.

Frequently Asked Questions

What exactly is a paddle dryer?

A paddle dryer is like a big, special oven that uses spinning paddles to dry things. It’s a type of indirect heat dryer, meaning the heat comes from the paddles and the outside shell, not directly from flames. These paddles mix the material as it dries, making sure everything gets heated evenly and dries faster. It’s great for all sorts of stuff, from sticky goo to little bits of material.

How do paddle dryers work?

You put the wet stuff into the dryer. Heat travels through hollow paddles and the dryer’s walls, warming everything up. As the paddles spin, they stir the material, constantly moving it around so it touches the hot parts. This helps the water turn into vapor and escape, leaving the material dry.

Can paddle dryers handle materials that are sensitive to heat?

Yes, they can! Paddle dryers use indirect heating and spin at slow speeds, which is gentle. You can also adjust the temperature to be just right, so the material doesn’t get damaged or change in a bad way.

How long does it usually take to set up a paddle dryer?

It really depends on how big and complicated the dryer is. Smaller ones might be ready in about a week. But if it’s a really big system with lots of fancy controls, it could take a few weeks. Planning ahead helps make the setup go faster.

What kind of upkeep do paddle dryers need?

Keeping a paddle dryer running well involves some regular checks. You’ll need to oil the moving parts, look at the seals to make sure they’re not worn out, and clean the parts that transfer heat. Checking the control systems is important too. How much time this takes depends on the dryer’s size and what you’re drying.

Why should I pick your company for a paddle dryer?

We’ve been making these dryers for over 23 years and know our stuff. We build them specifically for what you need, not just a one-size-fits-all approach. Plus, we offer great support after you buy it, like helping with installation, training your staff, and having the parts you might need readily available. We also test them thoroughly to make sure they work perfectly.

AS Engineers is a renowned name in the industry, offering high-quality paddle dryers designed for efficient and reliable drying of various materials. With extensive experience and a commitment to innovation, AS Engineers provides comprehensive solutions tailored to meet the specific needs of their clients. Their expertise spans across design, manufacturing, installation, and after-sales service, ensuring optimal performance and customer satisfaction.

Whether you require a standard model or a custom-built solution, AS Engineers is your trusted partner for all your paddle dryer requirements in India.

visit their websites to know more:

AS Engineers: https://lnkd.in/dd3F_FYy

Paddle Dryer: https://paddledryer.in/

Sludge Dryer: https://sludgedryer.in/