Environmental Compliance: A Complete Guide for Industrial Operations and Sustainability Teams

In 2023, a prominent chemical company in India was fined ₹2.4 crore for discharging untreated wastewater into a nearby canal. The violation wasn’t due to a lack of infrastructure—it was the result of overlooked environmental compliance procedures.

This wasn’t an isolated case. Across sectors—from manufacturing and mining to food processing and real estate—environmental compliance has moved from a checklist to a boardroom priority.

Whether you’re an EHS officer, plant manager, sustainability lead, or business owner, staying compliant with environmental laws is no longer optional. It’s essential for:

- Avoiding legal penalties

- Maintaining operational continuity

- Building public and investor trust

- Qualifying for global supply chains and certifications

This guide will give you a clear, practical understanding of:

- What environmental compliance really means

- Which laws, permits, and documentation you need

- How to prepare for audits and inspections

- Common mistakes to avoid

- How to integrate compliance with broader sustainability goals

Let’s start by understanding what we mean when we talk about environmental compliance.

Table of Contents

What Is Environmental Compliance?

Environmental compliance refers to the act of adhering to environmental laws, regulations, standards, and permit conditions that apply to your business operations.

In simple terms, it means doing what the law requires to protect the environment from the impacts of your facility.

A Working Definition

Environmental compliance is the process of:

- Identifying relevant environmental laws and guidelines

- Obtaining all necessary licenses, consents, and permits

- Operating your plant or facility within those legal boundaries

- Monitoring and recording environmental performance

- Reporting data and taking corrective action when needed

It applies to all types of pollution—air, water, soil, and noise—and includes proper handling of waste, emissions, chemicals, and natural resources.

Who Needs to Comply?

Compliance is required for:

- Manufacturing plants (steel, cement, textiles, food, pharma)

- Power generation units

- Mining and mineral processing

- Infrastructure and construction companies

- Municipal corporations and STPs

- Hospitals, hotels, and high-rise residential societies

Even smaller facilities, like workshops and fuel stations, must comply with certain local or national environmental norms.

Is It Just a Legal Obligation?

While legal compliance is the foundation, environmental compliance also supports:

- Business continuity – Environmental shutdowns can halt production

- Brand reputation – Customers and investors demand ethical operations

- Supply chain qualification – Global buyers often require environmental certifications like ISO 14001

- Risk mitigation – Prevents spills, leaks, and disasters that can cost lives and destroy assets

Types of Compliance Obligations

Depending on your industry, environmental compliance can include:

- Permits and licenses for air, water, and waste discharge

- Consent to Establish (CTE) and Consent to Operate (CTO)

- Online monitoring systems (CEMS, EQMS, STP/ETP)

- Annual audit reports and compliance statements

- Hazardous waste manifest tracking

- Emergency response protocols and staff training

Voluntary vs. Mandatory Compliance

- Mandatory compliance is defined by national/state laws (e.g., CPCB rules, EPA regulations)

- Voluntary compliance includes initiatives like:

- ISO 14001 certification

- ESG (Environmental, Social, Governance) reporting

- Internal environmental management systems (EMS)

Forward-looking companies adopt both to reduce risk and improve performance.

Why Environmental Compliance Is Crucial for Businesses

Many businesses view environmental compliance as a bureaucratic formality—something to manage just before inspections or during audits. But the reality is much broader: environmental compliance is a cornerstone of operational, financial, and reputational stability.

Here’s why it matters more today than ever before.

1. Legal Accountability and Risk Management

Non-compliance with environmental laws can lead to:

- Fines and penalties

- Legal action or shutdown orders

- Cancellation of licenses

- Criminal charges against plant heads or directors in severe cases

In India, the Environment (Protection) Act, 1986 empowers pollution control boards to impose heavy fines or initiate closure of units without court orders. In the U.S., the EPA’s enforcement actions have resulted in multimillion-dollar penalties and even jail time for repeat violations.

Proactive compliance protects your organization from unpredictable regulatory risks.

2. Avoidance of Operational Interruptions

Many industrial units fail to factor in how non-compliance can halt production entirely. Regulatory bodies can issue:

- Stop-work notices

- Show-cause letters

- Utility disconnections (power/water)

These interruptions not only affect revenue but also damage customer confidence. Environmental compliance ensures your plant continues running smoothly without fear of shutdowns.

3. Protection of Brand and Public Reputation

In today’s information age, any environmental violation can be publicly exposed within hours—leading to:

- Media scrutiny

- Community protests

- Reputational loss

Consumers, investors, and employees now expect businesses to go beyond compliance and show commitment to environmental responsibility. One incident can undo years of brand-building.

4. Unlocking Global Market Access

Buyers, especially in the EU, U.S., and Japan, increasingly require suppliers to:

- Follow environmental regulations

- Comply with ISO 14001 or similar standards

- Submit ESG reports

- Undergo third-party audits

Failing to meet environmental requirements can disqualify you from high-value supply chains.

5. Cost Reduction and Resource Optimization

Compliance doesn’t just prevent penalties—it can reduce costs in areas like:

- Energy and water consumption

- Waste management

- Raw material usage

For example, a company installing proper effluent treatment and reuse systems can cut fresh water use by 40–60%, leading to long-term savings.

Environmental compliance, when integrated into operations, often improves efficiency.

6. Supporting Sustainable Development and CSR Goals

Environmental compliance aligns with:

- Sustainable Development Goals (SDGs)

- Corporate Social Responsibility (CSR) frameworks

- Net-zero and climate change adaptation initiatives

Companies can tie compliance to broader goals like zero waste, carbon neutrality, or water positivity, creating stronger stakeholder alignment.

7. Attracting Ethical Investors and Capital

Environmental performance is now a key metric in:

- ESG scores

- Green bond eligibility

- Impact investing strategies

Investors assess a company’s environmental compliance history before approving capital. A poor compliance record can reduce access to both equity and debt funding.

Key Benefits Summary

| Benefit | Description |

|---|---|

| Legal protection | Avoids fines, shutdowns, and criminal charges |

| Uninterrupted operations | Prevents surprise inspections and compliance delays |

| Enhanced brand value | Builds public trust and media credibility |

| Market eligibility | Qualifies for global supply chain partnerships |

| Operational efficiency | Lowers waste, energy, and utility bills |

| Sustainability alignment | Supports CSR and environmental mission statements |

| Investor appeal | Improves ESG profile and green financing options |

Key Areas of Environmental Compliance

Environmental compliance is not limited to just pollution control or emissions reporting. It covers multiple domains—from how you handle wastewater and solid waste to how you store chemicals or manage noise. Each area is governed by specific laws, permits, and operational standards.

Let’s explore the key focus areas you must monitor to stay fully compliant.

1. Air Emissions Compliance

Air pollution is heavily regulated across the world, especially in industries like cement, chemicals, power generation, and steel.

Key Requirements:

- Stack emission monitoring for PM, SOx, NOx, VOCs, and CO

- Installation of air pollution control equipment (APCE) such as bag filters, wet scrubbers, ESPs, or catalytic converters

- Online Continuous Emission Monitoring Systems (CEMS) connected to regulatory boards

- Permissible emission limits as per CPCB/EPA or local PCB norms

Common Violations:

- Running APCE units at low efficiency

- Not maintaining calibration logs

- Bypassing scrubbers during maintenance

2. Water and Wastewater Compliance

This is a critical area, especially in food processing, textile, chemical, and pharmaceutical units.

Key Requirements:

- Effluent Treatment Plants (ETPs) or Sewage Treatment Plants (STPs) installed and maintained

- Effluent parameters like BOD, COD, TSS, oil & grease, pH, and heavy metals within prescribed limits

- Treated water reuse or safe disposal into drains, rivers, or municipal sewers

- Flow meters and EQMS (Effluent Quality Monitoring Systems) for real-time data transmission

Applicable Standards:

- Schedule VI of the Environment Protection Rules, 1986 (India)

- Clean Water Act (USA)

- Zero Liquid Discharge (ZLD) mandates for certain sectors

3. Solid Waste and Hazardous Waste Management

Poor handling of waste is a major cause of environmental non-compliance.

Key Requirements:

- Segregation of biodegradable, recyclable, and hazardous waste

- Labeling and storage as per MSDS and national waste rules

- Authorized disposal partners for hazardous or biomedical waste

- TSDF facility tie-ups (Treatment, Storage, Disposal Facilities)

- Online manifest tracking in many regions (e.g., India’s Form 10 system)

Types of Waste Covered:

- E-waste

- Biomedical waste

- Hazardous process sludge

- Plastic and packaging waste

- Construction and demolition debris

4. Chemical Storage and Spill Management

Many industrial units use solvents, fuels, acids, and other hazardous substances. Mishandling can lead to fires, explosions, and groundwater contamination.

Compliance Includes:

- Proper MSDS documentation and display at site

- Secondary containment systems for liquid storage

- Spill kits and emergency response plans readily available

- Training staff in safe handling and response protocols

- Inventory tracking and consumption records

5. Noise and Energy Regulations

Noise and energy use may not always result in visible pollution, but they are regulated—especially in sensitive zones and under ESG frameworks.

Key Requirements:

- Noise monitoring around DG sets, compressors, and heavy machinery

- Installation of acoustic enclosures or silencers

- Shift scheduling to limit night-time exposure

- Energy usage reporting under PAT schemes or sustainability audits

- Adoption of energy-efficient motors, drives, and lighting

6. Documentation, Reporting, and Environmental Records

This is often the most underestimated aspect of compliance—and the most likely to lead to audit failures.

Must-Have Documentation:

- Environmental clearance letters (ECs)

- Consent to Establish and Consent to Operate (CTE/CTO)

- Stack and effluent monitoring reports

- Hazardous waste manifests

- Occupational health and safety records

- Annual Environmental Statement (Form V in India)

- Corrective Action Reports for past audit findings

Tip: Always maintain digital backups and create a compliance calendar with reminders for all reporting deadlines.

Top Environmental Laws and Regulations You Must Know

Understanding the legal framework behind environmental compliance is essential for any business. Each country has its own set of environmental laws, regulatory bodies, and enforcement mechanisms. Ignorance of these laws isn’t an excuse—it’s a liability.

This section outlines key environmental laws in India, the U.S., and global standards that every compliance officer, operations manager, and business owner should be aware of.

Environmental Laws in India

India’s environmental laws are governed by the Ministry of Environment, Forest and Climate Change (MoEFCC) and enforced by the Central Pollution Control Board (CPCB) and respective State Pollution Control Boards (SPCBs).

Key Indian Acts and Rules:

- The Environment (Protection) Act, 1986

- Umbrella legislation for air, water, noise, and waste

- Empowers MoEFCC and CPCB to set standards and issue directions

- The Water (Prevention and Control of Pollution) Act, 1974

- Governs the discharge of effluents into water bodies

- Requires Consent to Establish (CTE) and Consent to Operate (CTO)

- The Air (Prevention and Control of Pollution) Act, 1981

- Regulates emissions from industries and vehicles

- Enforces emission norms and stack monitoring

- Hazardous and Other Wastes (Management and Transboundary Movement) Rules, 2016

- Covers generation, storage, transport, and disposal of hazardous waste

- Covers generation, storage, transport, and disposal of hazardous waste

- Solid Waste Management Rules, 2016

- Mandates segregation, collection, and treatment of solid municipal waste

- Mandates segregation, collection, and treatment of solid municipal waste

- E-Waste Management Rules, 2016

- For electrical and electronic equipment manufacturers and recyclers

- For electrical and electronic equipment manufacturers and recyclers

- Plastic Waste Management Rules, 2016 (Amended 2022)

- Regulates production, import, and disposal of plastic packaging

- Regulates production, import, and disposal of plastic packaging

- Batteries Waste Management Rules, 2022

- Introduces Extended Producer Responsibility (EPR)

- Introduces Extended Producer Responsibility (EPR)

- Noise Pollution (Regulation and Control) Rules, 2000

- The Forest (Conservation) Act, 1980 and Wildlife Protection Act, 1972

- Relevant for infrastructure projects and environmental clearance (EC) processes

Environmental Regulations in the United States

The Environmental Protection Agency (EPA) oversees environmental compliance and enforcement in the U.S.

Key U.S. Environmental Laws:

- Clean Air Act (CAA)

- Regulates air emissions and sets National Ambient Air Quality Standards (NAAQS)

- Clean Water Act (CWA)

- Controls water pollution and discharge from point sources

- Resource Conservation and Recovery Act (RCRA)

- Manages hazardous and non-hazardous solid waste

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA or Superfund)

- Addresses cleanup of contaminated sites

- Toxic Substances Control Act (TSCA)

- Governs production, use, and disposal of chemical substances

Global Standards and Voluntary Frameworks

As companies operate across borders or seek investment from global markets, voluntary environmental frameworks are becoming just as important as local regulations.

Key Global Standards:

- ISO 14001: Environmental Management Systems (EMS)

- Provides a structured framework for managing environmental responsibilities

- Recognized globally and often required by international clients

- ESG Compliance (Environmental, Social, and Governance)

- A framework used by investors to assess a company’s sustainability performance

- European Union REACH Regulation

- Registration, Evaluation, Authorisation, and Restriction of Chemicals

- EU RoHS Directive

- Restriction of Hazardous Substances in electronic products

- UN Sustainable Development Goals (SDGs)

- Especially SDG 6 (Clean Water), SDG 12 (Responsible Consumption), and SDG 13 (Climate Action)

Why This Matters

Compliance isn’t just about avoiding penalties—it’s about:

- Winning contracts with global corporations

- Reducing operational risks

- Qualifying for green certifications and investor funding

In many industries, being unaware of applicable environmental laws can cost you projects, licenses, or even legal protection in the case of an incident.

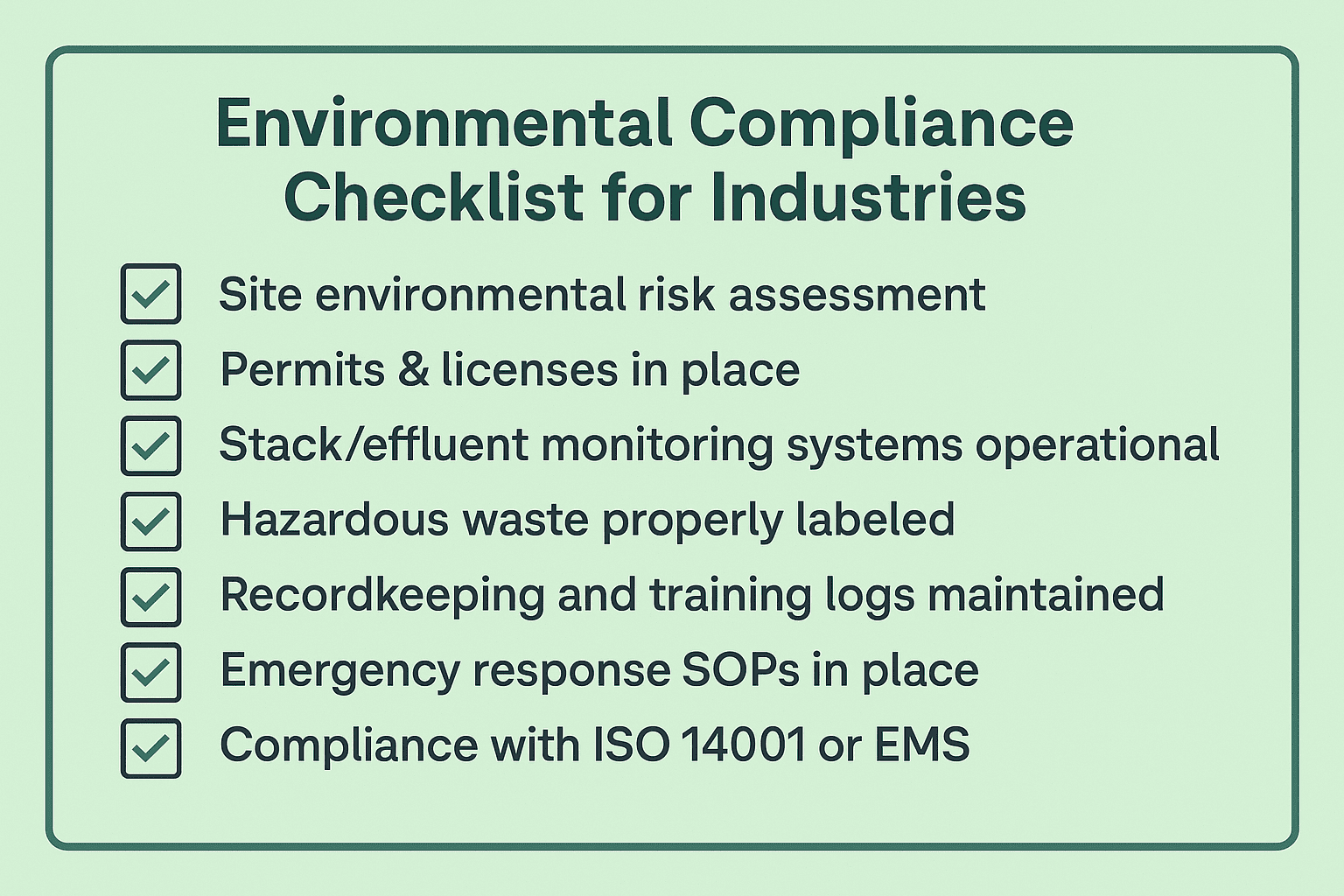

Environmental Compliance Checklist for Industries

Staying compliant isn’t just about installing pollution control equipment or submitting annual reports. It requires consistent, proactive checks across multiple environmental domains. A well-maintained checklist helps:

- Prevent violations before they occur

- Prepare for inspections or audits

- Ensure site-wide environmental safety

- Maintain records aligned with ISO 14001 and legal requirements

Use the following industrial compliance checklist as your internal baseline.

1. Regulatory Permits and Approvals

- Valid Consent to Establish (CTE) and Consent to Operate (CTO) obtained

- Environmental Clearance (EC) letter available (if applicable)

- Fire, hazardous storage, and factory licenses updated

- Copies of all licenses physically and digitally stored

- Approval from municipal/local body for discharge (if required)

2. Air Emission Compliance

- Stack emission monitoring in place (PM, NOx, SOx, VOCs)

- Online CEMS connected to pollution control board (where applicable)

- Air Pollution Control Equipment (APCE) functional and serviced

- Calibration logs for analyzers and flow meters maintained

- Stack sampling reports within permissible limits

3. Effluent and Wastewater Management

- Effluent Treatment Plant (ETP) or Sewage Treatment Plant (STP) operational

- Online Effluent Quality Monitoring System (EQMS) installed

- Flow meters and pH/DO sensors calibrated and logged

- Reuse plan for treated water implemented (if possible)

- Final discharge meets prescribed CPCB/SPCB norms

4. Solid and Hazardous Waste Handling

- Solid waste is segregated and stored as per Solid Waste Rules

- Hazardous waste properly labeled and stored in leak-proof containers

- TSDF tie-up agreement in place

- Waste manifest tracking system updated (e.g., Form 10 in India)

- Annual hazardous waste returns submitted on time

5. Chemical Handling and Storage

- Material Safety Data Sheets (MSDS) for all chemicals available on site

- Secondary containment provided for all storage tanks and drums

- Spill response kits placed at high-risk zones

- Chemical inventory and usage records maintained monthly

- Trained personnel assigned for handling and emergency response

6. Noise and Energy Monitoring

- DG sets equipped with acoustic enclosures

- Noise levels monitored near sensitive areas (e.g., boundary walls)

- Preventive maintenance of compressors and blowers scheduled

- Energy audits conducted periodically

- Adoption of energy-efficient equipment (VFDs, LED lights, etc.)

7. Documentation and Reporting

- All environmental licenses, permits, and clearances are up-to-date

- Logbooks for stack/effluent monitoring maintained daily

- Annual Environmental Statement (Form V in India) submitted

- Compliance reports submitted on time (e.g., six-monthly EC compliance)

- Audit findings documented and corrective actions tracked

8. Training and Awareness

- Monthly EHS training sessions conducted and logged

- Emergency response drills performed and documented

- New staff undergo induction covering compliance basics

- SOPs displayed near control panels and hazardous zones

- Contractor and vendor training records maintained

9. Internal and External Audits

- Periodic self-inspections conducted using this checklist

- Third-party environmental audit carried out annually

- Audit reports available for last 3–5 years

- Corrective action plans implemented for past non-conformities

- Review meetings conducted with department heads

Printable Summary: Environmental Compliance Checklist

| Area | Key Checks Included |

|---|---|

| Regulatory Permits | CTE, CTO, EC, municipal approval |

| Air Emissions | CEMS, APCE, stack reports, calibrations |

| Water/Effluent Management | ETP/STP, EQMS, final discharge norms |

| Waste Management | TSDF tie-up, labeling, manifest tracking |

| Chemical Storage | MSDS, spill kits, containment |

| Noise & Energy | DG controls, noise log, energy audits |

| Documentation & Reporting | Logbooks, Form V, compliance submissions |

| Training & Awareness | Staff SOPs, drills, contractor training |

| Audits | Internal & third-party audits, action plans |

Common Mistakes That Lead to Environmental Non-Compliance

Even with the best intentions, many companies fall short of environmental compliance due to oversight, poor systems, or lack of awareness. These errors can lead to penalties, shutdowns, or reputational damage—most of which are entirely preventable.

Below are the most frequent missteps observed during audits and inspections, along with actionable ways to correct them.

1. Failure to Renew Environmental Permits on Time

What Goes Wrong:

Consent to Operate (CTO), Consent to Establish (CTE), and Environmental Clearances (EC) often have expiration dates. Teams either forget to renew them or assume ongoing validity.

Impact:

Operating without valid permits is a punishable offense under most environmental laws.

How to Avoid It:

- Maintain a centralized compliance calendar

- Set up alerts at least 60 days before expiry

- Assign a responsible officer for renewals

2. Operating Pollution Control Equipment Inefficiently

What Goes Wrong:

Dust collectors, scrubbers, and ETPs are installed but poorly maintained. Filters clog, dosing is incorrect, or equipment runs only during inspections.

Impact:

Results in exceedances during stack/effluent sampling. Can lead to CPCB/SPCB penalties and loss of credibility.

How to Avoid It:

- Perform monthly performance audits

- Maintain logs of flow rates, pressure drops, and dosing

- Sign annual maintenance contracts (AMC) with OEMs

3. Poor Documentation and Recordkeeping

What Goes Wrong:

Audit trails for emissions, hazardous waste, and water consumption are either missing or not updated. Many rely on verbal reports.

Impact:

Inability to prove compliance during surprise inspections or legal proceedings.

How to Avoid It:

- Keep digital and physical copies of all records

- Update logbooks daily

- Train staff on accurate data entry and reporting

4. Ignoring Changes in Legal Requirements

What Goes Wrong:

Many companies follow outdated rules or miss amendments (e.g., changes to plastic waste rules or EPR norms).

Impact:

Even previously compliant systems may become non-compliant under new laws.

How to Avoid It:

- Subscribe to updates from CPCB/SPCB websites

- Attend annual EHS workshops or legal briefings

- Engage consultants for regulatory updates

5. Not Conducting Regular Internal Audits

What Goes Wrong:

Companies only prepare for statutory audits and skip internal reviews. Small issues go unnoticed until they escalate.

Impact:

Chronic non-compliance, poor risk visibility, and recurring failures

How to Avoid It:

- Conduct quarterly internal compliance reviews

- Use structured audit checklists (as in the previous section)

- Include all departments—production, EHS, HR, stores

6. Inadequate Employee Training

What Goes Wrong:

Operators and floor staff lack awareness of procedures for spill response, chemical handling, or waste segregation.

Impact:

Human error leads to environmental incidents and audit observations.

How to Avoid It:

- Schedule monthly EHS training sessions

- Use visual SOPs and on-floor signage

- Test emergency drills every quarter

7. Delaying Corrective Action After Audit Observations

What Goes Wrong:

Audit reports are filed, but no action is taken. The same issues appear year after year.

Impact:

Regulators view repeated findings as willful negligence and may escalate enforcement.

How to Avoid It:

- Maintain a corrective action tracker

- Assign accountability and follow up

- Include non-conformance closure in monthly meetings

Summary Table: Mistakes vs. Preventive Actions

| Mistake | Preventive Action |

|---|---|

| Late permit renewals | Compliance calendar and alerts |

| Inefficient APC/ETP operation | Monthly audits, AMCs, logbooks |

| Poor documentation | Daily recordkeeping, cloud backups |

| Outdated legal knowledge | Subscribe to CPCB updates, annual workshops |

| No internal audits | Quarterly reviews using a structured checklist |

| Untrained workforce | Monthly training, SOP displays, mock drills |

| Ignoring audit findings | Assign closure deadlines, track through reviews |

Personal Story: How One Oversight Cost a Manufacturer ₹12 Lakhs—and How We Fixed It

In early 2021, I was approached by a mid-sized pharmaceutical company located in western India. They had received a show-cause notice from the State Pollution Control Board (SPCB), threatening suspension of their Consent to Operate. The reason? Their Effluent Treatment Plant (ETP) wasn’t meeting discharge norms, and they lacked updated documentation.

This wasn’t a new company. They had operated for over 12 years and had a well-staffed EHS department. But like many firms, they had focused heavily on production and neglected compliance upkeep.

The Root of the Problem

Upon inspection, we discovered:

- Effluent pH and COD levels were exceeding limits set in their CTO

- Their last stack and effluent analysis reports were 9 months old

- The plant’s flow meters and EQMS systems weren’t calibrated

- Operator logs were handwritten and inconsistent

- No corrective action had been taken after their last third-party audit

Additionally, their CTE had expired three months earlier due to an expansion—and no renewal application had been filed.

The SPCB cited five violations and demanded a formal compliance roadmap within 15 days.

The Financial and Operational Risk

The company faced:

- A ₹2 lakh immediate fine

- An estimated ₹10 lakh+ in possible losses from a 15-day shutdown

- Reputational risk with buyers (including overseas clients)

More than the penalty, they feared losing credibility with regulators and business partners.

Our 60-Day Corrective Strategy

We quickly assembled a compliance team consisting of:

- The EHS officer

- Maintenance engineer

- Operations head

- External auditor (us)

- A third-party calibration agency

Here’s what we implemented:

- Emergency calibration of all monitoring equipment

- Daily tracking logbooks redesigned in a digital format

- Fast-tracked renewal of the Consent to Operate (filed within 7 days)

- Jar testing and ETP dosing optimization to restore discharge quality

- Internal audit SOP introduced with weekly checkpoints

- Sent a compliance action report to SPCB with a Gantt chart and proof of action

Within four weeks, discharge parameters fell within the prescribed range. By Day 45, SPCB acknowledged compliance. By Day 60, the unit received its renewed CTO and resumed normal operations.

What We Learned

- Neglecting compliance for even a few months can threaten business continuity

- Most violations are preventable with better monitoring, documentation, and communication

- Proactive engagement with regulators—rather than avoiding them—is a smart strategy

- Empowering on-ground teams with knowledge and SOPs can make a lasting difference

Today, the company runs quarterly internal audits and hasn’t had a single compliance issue since.

Environmental Compliance vs Environmental Sustainability: What’s the Difference?

Many professionals use the terms compliance and sustainability interchangeably—but they aren’t the same. While they often overlap, each plays a distinct role in how organizations manage their environmental impact.

Understanding the difference is key to developing a well-rounded environmental strategy that not only meets regulatory standards but also builds long-term value.

What Is Environmental Compliance?

Environmental compliance refers to an organization’s obligation to follow environmental laws, regulations, and permit conditions as defined by government agencies (such as CPCB, EPA, or local authorities).

Characteristics:

- Legally required

- Non-compliance leads to penalties or shutdowns

- Driven by pollution control norms, licensing, and documentation

- Enforced through inspections, reports, and audits

Example:

A textile plant installing a Zero Liquid Discharge (ZLD) system to meet state environmental board norms is practicing compliance.

What Is Environmental Sustainability?

Environmental sustainability, on the other hand, is a voluntary and strategic approach to reduce environmental impact, often going beyond what the law requires.

Characteristics:

- Long-term and future-focused

- Voluntary or standards-based (ISO 14001, ESG, Net Zero)

- Driven by company values, CSR goals, and stakeholder expectations

- Supports climate action, biodiversity, and resource preservation

Example:

The same textile plant adopting solar energy and recycling process heat to reduce carbon emissions is pursuing sustainability.

Key Differences: Compliance vs Sustainability

| Feature | Environmental Compliance | Environmental Sustainability |

|---|---|---|

| Purpose | Legal adherence | Long-term environmental impact reduction |

| Motivation | Government regulations | Corporate values, ESG, market pressure |

| Scope | Specific, measurable legal requirements | Broader environmental performance goals |

| Enforcement | Mandatory by law | Voluntary, self-driven or stakeholder-led |

| Examples | Discharge limits, permits | Renewable energy, circular economy, carbon neutrality |

| Impact | Avoids penalties | Builds reputation, resilience, and value |

Why Businesses Need Both

- Compliance keeps your license to operate.

- Sustainability secures your license to grow.

Regulators want to see minimum legal standards met. Investors, customers, and communities expect more—they want proof that your business is future-ready and environmentally responsible.

Leading companies now treat compliance as the foundation, and sustainability as the evolution.

Example Integration:

A pharmaceutical company installs a wastewater treatment plant (ETP) to meet CPCB discharge norms (compliance), but then reuses 80% of treated water in cooling systems and landscaping (sustainability).

The Role of ISO 14001 and Environmental Management Systems (EMS)

While staying compliant with environmental laws is critical, companies that want to operate responsibly, scale globally, and attract ESG-conscious investors are increasingly adopting ISO 14001-certified Environmental Management Systems (EMS).

This globally recognized framework provides a structured, repeatable, and auditable process for managing environmental responsibilities.

What Is ISO 14001?

ISO 14001 is an international standard that sets out the criteria for an effective Environmental Management System (EMS). It helps organizations:

- Identify environmental risks and impacts

- Set performance objectives and controls

- Monitor, review, and improve practices

- Ensure legal and regulatory compliance

- Align with sustainability and ESG goals

ISO 14001 is suitable for businesses of all sizes and sectors, including manufacturing, real estate, logistics, and services.

Core Elements of ISO 14001 EMS

- Environmental Policy

- A top-level declaration of intent and commitment to environmental responsibility.

- Planning

- Identification of environmental aspects and legal obligations

- Risk and opportunity assessment

- Objectives and targets

- Implementation and Operation

- Training and awareness

- Communication and documentation control

- Operational control procedures

- Emergency preparedness

- Checking and Corrective Action

- Monitoring and measurement of emissions, effluents, waste

- Compliance evaluations

- Internal audits

- Non-conformance tracking and resolution

- Management Review

- Leadership reviews EMS performance regularly

- Adjustments made for continual improvement

Benefits of Implementing ISO 14001

| Benefit | Impact |

|---|---|

| Regulatory Assurance | Ensures all legal obligations are identified and met |

| Audit Readiness | Structured documentation and traceability |

| Operational Efficiency | Reduces waste, energy use, and environmental risk |

| Global Market Access | Required or favored by many international buyers |

| Stakeholder Trust | Enhances brand value among investors, customers |

| Sustainability Alignment | Supports ESG reporting, SDGs, and net-zero goals |

EMS vs Compliance Systems

| Element | Basic Compliance Program | ISO 14001 EMS |

|---|---|---|

| Focus | Legal adherence only | Legal + performance improvement |

| Approach | Reactive | Proactive and preventive |

| Structure | Disconnected documentation | Integrated and standardized |

| Review Process | Irregular or audit-driven | Built-in periodic reviews |

| Recognition | Internal or local | Globally certified and recognized |

Is ISO 14001 Mandatory?

No. ISO 14001 is a voluntary certification, but in many industries—especially export-driven sectors—it’s becoming a de facto requirement. For example:

- Automotive OEMs demand it from component suppliers

- Pharmaceutical buyers assess it for risk management

- Green financing institutions view it as a trust indicator

How to Get Certified

- Conduct a gap analysis

- Design and document your EMS

- Train staff and conduct internal audits

- Undergo a third-party certification audit by an accredited body (e.g., TUV, SGS, DNV)

- Maintain and improve through surveillance audits

Tips to Stay Compliant Year-Round

Environmental compliance isn’t a one-time event tied to audits or permit renewals. It’s an ongoing responsibility that requires systems, discipline, and awareness across all departments.

Below are actionable, experience-tested tips to help your organization maintain continuous environmental compliance throughout the year—without last-minute panic or penalties.

1. Maintain a Digital Environmental Compliance Calendar

- List all compliance obligations: permit renewals, report due dates, audits, waste pickups

- Include daily, weekly, monthly, quarterly, and annual activities

- Assign ownership to specific individuals or departments

- Use shared digital tools (Google Calendar, project management software, or compliance software)

Pro tip: Set alerts 30–60 days before due dates to avoid missed submissions or expiries.

2. Conduct Monthly Compliance Reviews

Every 30 days, verify:

- Stack and effluent monitoring reports are logged

- Waste is segregated, labeled, and stored properly

- Daily operational logs (APCE, ETP) are signed and filed

- Incidents or near-misses are recorded and reviewed

- Environmental equipment is functioning as per SOPs

These internal check-ins can uncover small issues before they grow into regulatory violations.

3. Train and Re-Train Your Workforce

Compliance is a team sport. Every operator, technician, and contractor must:

- Know the environmental impact of their work

- Follow standard operating procedures (SOPs)

- Respond effectively during spills, leaks, or alarms

Tip: Create short monthly refresher sessions and rotate topics—waste handling, spill response, chemical storage, reporting, etc.

4. Use a Compliance Dashboard or Software

For large facilities or multi-location companies, consider:

- Environmental Management Information Systems (EMIS)

- GRC (Governance, Risk, and Compliance) software

- ISO 14001-aligned performance tracking tools

These platforms offer:

- Centralized document storage

- Deadline alerts

- Compliance status snapshots

- Automatic report generation

5. Review All Vendor and Contractor Activities

Many compliance violations stem from third-party contractors or waste handlers.

You should:

- Verify they have valid licenses (e.g., TSDF approvals, transport permissions)

- Conduct periodic audits of vendor facilities

- Include compliance clauses in all work contracts

Example: A transporter dumping waste in unauthorized locations can lead to penalties for your company, not just the vendor.

6. Conduct Periodic Third-Party Audits

Even with internal reviews, external audits bring objectivity and fresh insights. Ideally:

- Schedule one external audit per year

- Include ISO 14001, CPCB/SPCB norms, and industry best practices

- Use the findings to create a Corrective and Preventive Action (CAPA) plan

7. Keep Documents Audit-Ready

Create a “compliance kit” with:

- Valid licenses and permits

- Latest stack/effluent test reports

- Logbooks and calibration certificates

- MSDS and waste manifests

- Recent internal and external audit reports

Keep both digital and hard copies accessible to EHS leads and plant managers.

8. Align Compliance With Broader Business Goals

Tie compliance into:

- CSR and ESG initiatives

- Monthly management reviews

- KPI dashboards for sustainability or operations

When compliance is linked to incentives, leadership attention increases—and so does performance.

FAQs About Environmental Compliance

1. What is environmental compliance in simple terms?

Environmental compliance means following laws and regulations that protect the environment. It includes proper handling of air emissions, wastewater, waste, and hazardous substances, and maintaining required permits and documentation.

2. Why is environmental compliance important for industries?

It helps avoid legal penalties, ensures smooth operations, builds public trust, and qualifies businesses for international supply chains and sustainability certifications.

3. Who regulates environmental compliance in India?

The Central Pollution Control Board (CPCB) and respective State Pollution Control Boards (SPCBs) regulate and enforce environmental laws under the Ministry of Environment, Forest and Climate Change (MoEFCC).

4. What are some examples of environmental compliance?

- Operating an Effluent Treatment Plant (ETP) within permitted discharge norms

- Installing Continuous Emission Monitoring Systems (CEMS)

- Storing hazardous waste with proper labeling and containment

- Renewing Consent to Operate (CTO) before expiry

- Submitting annual environmental statements (Form V)

5. What is the penalty for non-compliance with environmental laws?

Penalties include fines, plant shutdowns, suspension of licenses, and legal action. In India, violations under the Environment (Protection) Act, 1986 can lead to imprisonment and fines up to ₹1 lakh per day of continued offense.

6. What’s the difference between ISO 14001 and legal compliance?

Legal compliance is mandatory and based on government regulations. ISO 14001 is a voluntary certification that provides a structured system (EMS) to manage and improve environmental performance.

7. Is environmental compliance the same as sustainability?

No. Compliance is about meeting legal requirements. Sustainability goes further by reducing environmental impact voluntarily and aligning with long-term goals like carbon neutrality or water positivity.

8. How can small businesses stay compliant?

- Maintain valid permits

- Conduct basic environmental risk assessments

- Train staff on spill control and waste handling

- Keep clear records of monitoring and disposal

- Engage consultants for guidance or audits

Conclusion: Compliance Is the Foundation of Responsible Growth

Environmental compliance isn’t just about ticking boxes or avoiding penalties—it’s about protecting your business, your community, and the planet.

Whether you run a manufacturing unit, operate an effluent treatment plant, or manage sustainability in a corporate office, staying compliant is non-negotiable. From air emissions and water discharge to hazardous waste and documentation, every aspect requires structured oversight and active management.

In a world where environmental laws are tightening and sustainability expectations are rising, organizations that take compliance seriously are:

- More resilient

- More efficient

- More trusted by stakeholders

Compliance is the first step. Sustainability is the journey that follows.

Need Help with Compliance or Environmental Systems?

If you’re:

- Unsure about your facility’s current compliance status

- Preparing for an audit or ISO 14001 certification

- Planning to improve your environmental performance

We’re here to support you.