Delta Robots: A Comprehensive Guide to High-Speed Automation

In today’s fast-paced manufacturing environment, automation plays a pivotal role in streamlining production and increasing efficiency. Among the various types of automation technologies, delta robots have emerged as a popular choice for industries requiring high-speed, precise handling of lightweight products. If you are involved in sectors like food packaging, pharmaceuticals, or electronics, understanding the capabilities and advantages of delta robots can significantly improve your automation processes.

In this guide, we’ll explore what delta robots are, how they work, their applications, and why they are essential in modern industries. By the end of this article, you’ll have a deep understanding of delta robots and how they can revolutionize your automation systems.

Table of Contents

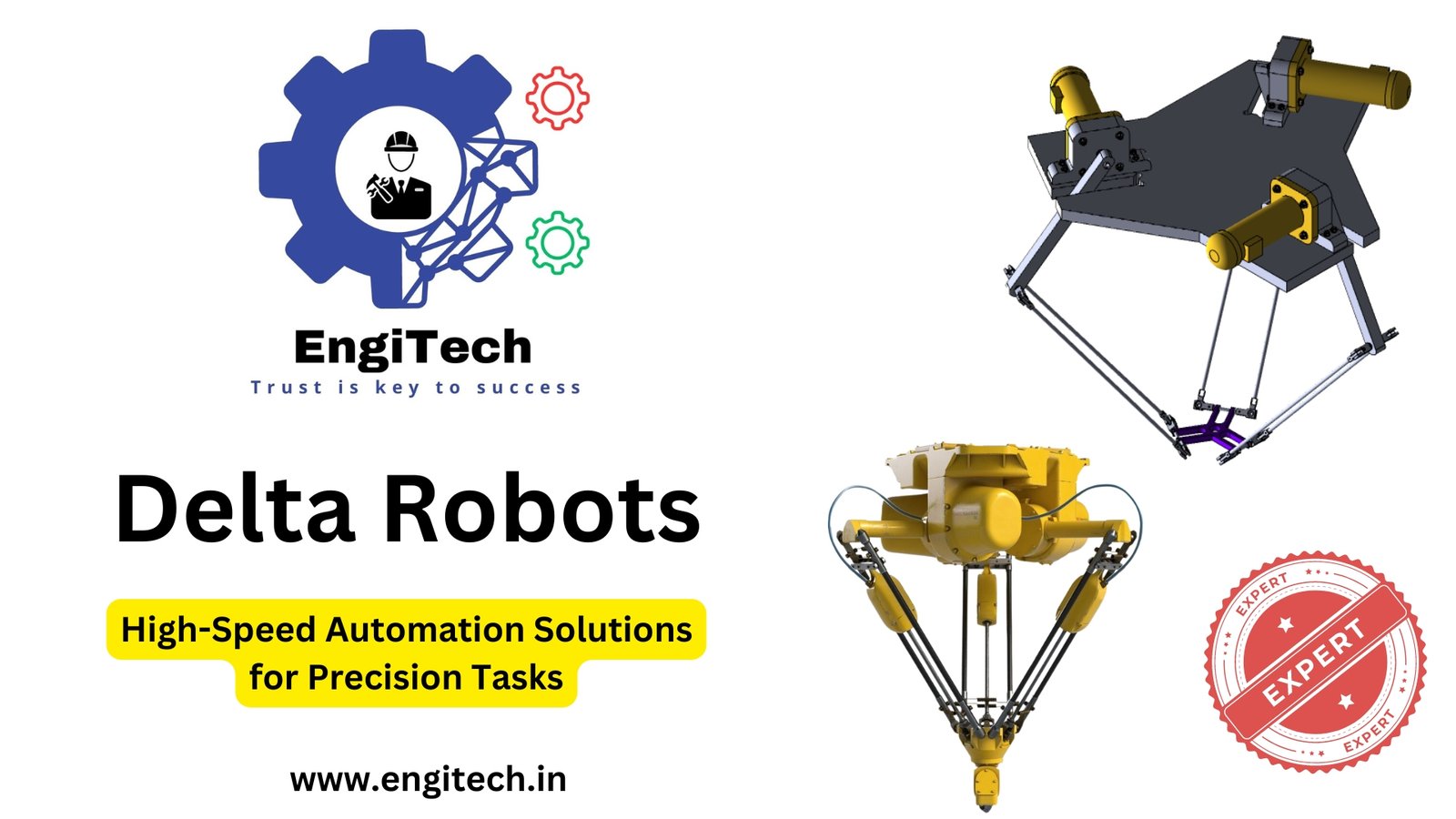

What Are Delta Robots?

A delta robot is a parallel-type robot consisting of three arms connected to universal joints at the base. Unlike traditional serial robots, which have arms arranged in a series, delta robots operate in a parallel structure, offering high-speed and precise movements. This robot configuration is well-suited for tasks that require fast and repetitive movements over a small area, such as picking, packing, and sorting.

How Delta Robots Work

Delta robots are equipped with three to four arms that converge at a single end-effector, which is responsible for handling products. Their design allows for simultaneous, synchronized movements of all arms, giving the end-effector the ability to move rapidly across the workspace. The robot’s arms are controlled by motors at the base, and this unique design enables:

- High-speed precision: Delta robots can perform more than 100 picks per minute, making them ideal for industries that demand speed without compromising accuracy.

- Lightweight handling: These robots are optimized for handling lightweight materials, typically under 5 kilograms.

- Multiple degrees of freedom: They can move along the X, Y, and Z axes while tilting and rotating the end-effector, offering flexibility for various applications.

Advantages of Delta Robots in Automation

Delta robots are prized for their high-speed capabilities, but their benefits extend beyond just speed. Here’s why delta robots are indispensable in modern automation:

1. Exceptional Speed

Delta robots are among the fastest robotic systems available, capable of performing operations like picking and placing at unparalleled speeds. This makes them the go-to choice for industries where throughput is critical, such as food packaging and pharmaceuticals.

2. High Precision

Despite their speed, delta robots maintain exceptional accuracy, thanks to their parallel arm structure. This precision ensures that tasks such as product sorting, assembling small components, or packaging items are executed with minimal error.

3. Compact Design

Due to the placement of motors at the base, delta robots have a compact structure that allows them to work in smaller spaces. This is especially useful in factories where maximizing floor space is essential.

4. Versatility in Applications

Delta robots are used in a variety of industries. Their ability to handle delicate materials at high speeds makes them invaluable in the food industry, while their precision is perfect for tasks in electronics and pharmaceuticals.

5. Energy Efficiency

Compared to other robotic systems, delta robots consume less power. Their lightweight design and reduced number of moving parts translate into lower energy consumption, making them a cost-effective solution for businesses.

Applications of Delta Robots in Industries

The versatility of delta robots makes them ideal for a wide range of industries. Below are some sectors where these robots have proven their worth:

1. Food and Beverage Industry

In the food industry, delta robots excel in high-speed picking and packing tasks. They are used to handle delicate products like pastries, fruits, and chocolates without damaging them. Their ability to operate in hygienic environments makes them a popular choice for packaging food items.

2. Pharmaceuticals

Delta robots are utilized in the pharmaceutical industry for tasks like sorting pills, filling containers, and packaging medicine. Their precision ensures that even small, delicate items are handled with care.

3. Electronics

In the electronics sector, delta robots are used to assemble small components with high precision. Their ability to work quickly and accurately makes them suitable for assembling parts like circuit boards, chips, and sensors.

4. Consumer Goods

Delta robots are also deployed in the packaging of consumer goods such as cosmetics, toys, and household items. Their speed and accuracy ensure efficient product handling and packaging.

Key Features of Delta Robots

When choosing a delta robot for your automation needs, several key features should be considered:

1. Payload Capacity

While delta robots are designed to handle lightweight items, different models offer varying payload capacities, usually ranging between 0.5 kg to 5 kg. Choose a model that matches your product’s weight requirements.

2. Work Envelope

Delta robots typically operate in a defined area, known as a work envelope. The size of this envelope will vary based on the robot’s arm length and the application. Ensure that the work envelope suits your production line layout.

3. Speed and Acceleration

Depending on the application, you may need a robot that offers a high pick rate per minute. Delta robots can often exceed 100 picks per minute, so select a model that matches the speed requirements of your industry.

4. End-Effector Compatibility

The end-effector is the part of the robot that interacts with the product. Depending on your specific needs (e.g., picking, placing, or packaging), you’ll want to ensure that the delta robot is compatible with the appropriate end-effectors.

How to Choose the Right Delta Robot for Your Business

Selecting the right delta robot for your business can be a daunting task, given the variety of models and specifications available. Here are some factors to consider:

1. Understand Your Application Needs

First, define the task the robot will perform. Are you looking for a robot to handle high-speed picking? Or do you need precision for assembling small components? Understanding the primary function of the robot will guide your selection.

2. Consider the Working Environment

Will the robot be operating in a cleanroom, food processing area, or a general manufacturing facility? Certain models are designed to meet specific environmental standards, such as IP ratings for dust and water protection or FDA compliance for food handling.

3. Evaluate Speed and Payload Requirements

If speed is your priority, look for a delta robot that offers a high pick rate. Conversely, if your products are heavier, opt for a model with a higher payload capacity, even if it means compromising slightly on speed.

4. Budget and ROI

Delta robots are an investment. Consider not only the upfront cost but also the long-term return on investment (ROI). Factors like energy efficiency, reduced downtime, and increased throughput should all factor into your decision.

Future Trends in Delta Robot Technology

The field of robotics is constantly evolving, and delta robots are no exception. Some trends that are shaping the future of delta robots include:

1. AI Integration

As artificial intelligence (AI) continues to advance, delta robots are expected to integrate more AI-based capabilities for smarter decision-making. This could enhance their ability to adapt to varying production conditions autonomously.

2. Increased Precision and Speed

Ongoing improvements in motors, sensors, and control algorithms will likely lead to even higher precision and faster operations in delta robots, making them indispensable in industries requiring ultra-fast automation.

3. Collaborative Robotics

As collaborative robots (cobots) rise in popularity, delta robots may also be designed to work alongside humans safely. This could open up new possibilities for combining human dexterity with robotic precision in production processes.

FAQs

1. What is a delta robot used for?

Delta robots are primarily used for high-speed, precise handling of lightweight products in industries like food packaging, pharmaceuticals, and electronics.

2. How fast can delta robots operate?

Delta robots can perform more than 100 picks per minute, making them one of the fastest robotic systems available.

3. What industries benefit most from delta robots?

Industries such as food and beverage, pharmaceuticals, electronics, and consumer goods benefit greatly from delta robots due to their speed, precision, and compact design.

Conclusion

Delta robots have revolutionized high-speed automation, offering unparalleled speed, precision, and versatility across various industries. Whether you’re in food packaging, electronics, or pharmaceuticals, these robots can dramatically improve your production efficiency. By understanding how delta robots work, their advantages, and the factors to consider when choosing the right model, you can make informed decisions that enhance your automation processes.

If you’re looking to stay ahead in the world of industrial automation, delta robots are an investment worth considering. Explore more on EngiTech to discover comprehensive resources on the latest innovations and applications in industrial automation. Stay updated with the newest trends and technologies to ensure your business remains competitive in an ever-evolving market.