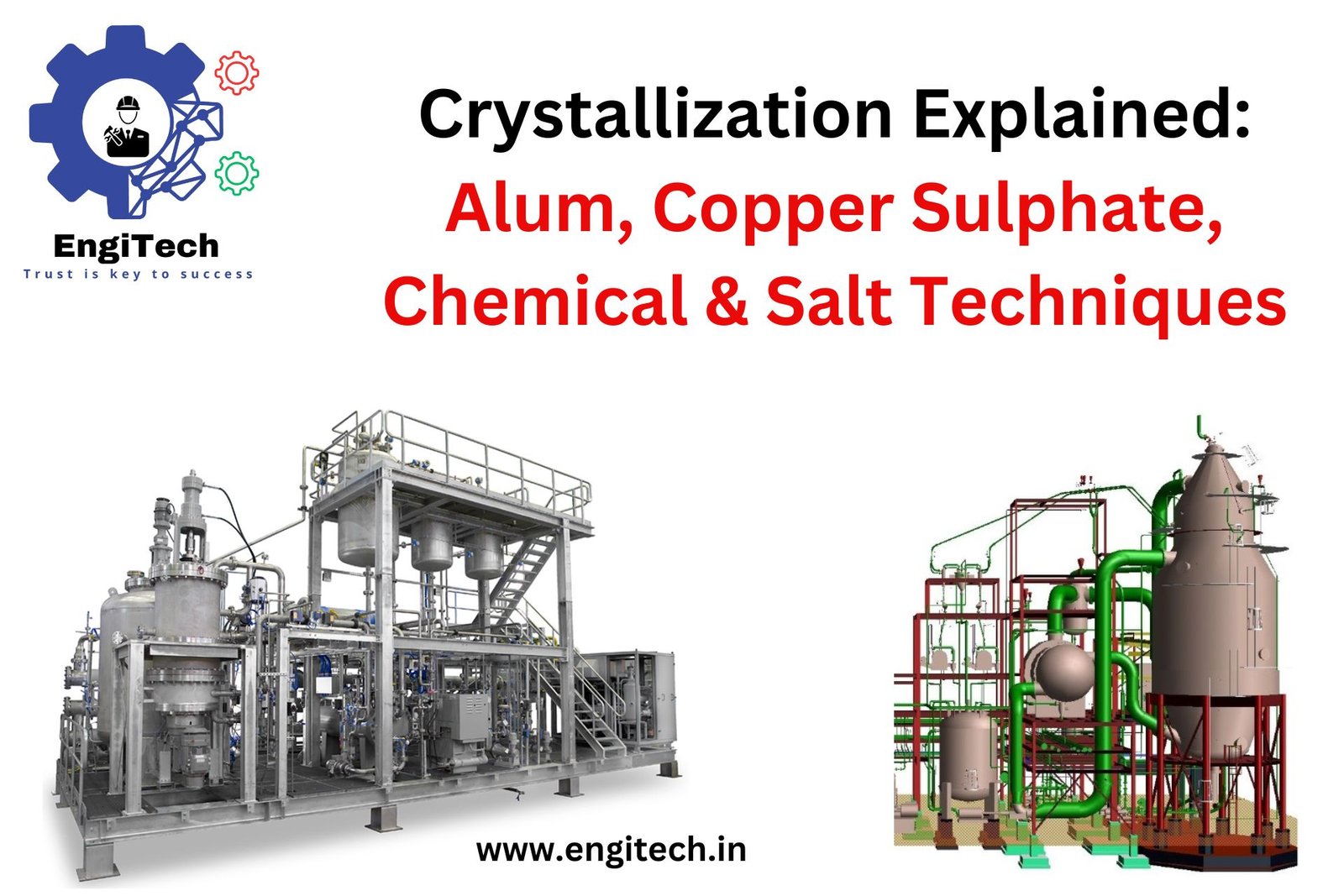

The Ultimate Guide to Crystallization: Alum, Chemical, Copper Sulphate, and Salt Crystallization

Crystallization is a cornerstone process in both industrial and scientific applications, facilitating the purification and formation of solid crystals from liquids or solutions. From producing alum crystals to purifying salt and copper sulphate, this process holds immense significance across industries.

In this guide, we’ll explore the fundamentals, techniques, and industrial relevance of crystallization, focusing on alum crystallization, chemical crystallization, copper sulphate crystallization, and the crystallization of salt. If you’re eager to learn how crystallization works or are searching for practical insights into its applications, you’re in the right place.

What Is Crystallization?

Crystallization is the process where a solid forms within a liquid solution or melt, adopting a highly ordered, lattice-like structure. This occurs when the solution becomes supersaturated, leading to nucleation and the growth of crystals.

Key Stages of Crystallization:

- Nucleation: Initial formation of microscopic crystal structures.

- Crystal Growth: Enlargement of these structures into visible crystals.

The Science Behind Crystallization

Crystallization is governed by principles of solubility, temperature, and concentration. The process can be induced in several ways:

- Cooling the Solution: Reduces solubility, prompting crystal formation.

- Evaporation: Removes solvent, increasing solute concentration.

- Chemical Reaction: Produces a less-soluble product that crystallizes.

Alum Crystallization

Alum, a double sulfate salt, is widely used in water treatment, leather tanning, and the cosmetics industry. Alum crystallization is both a practical method for producing alum and an engaging demonstration of crystallization science.

Steps for Alum Crystallization:

- Dissolve Alum Powder: Dissolve potassium or ammonium alum in hot water.

- Create a Saturated Solution: Gradually add alum until no more dissolves.

- Cool the Solution: Allow the solution to cool slowly to room temperature.

- Seed Crystals: Introduce a small alum crystal to promote nucleation.

- Crystal Growth: Leave the solution undisturbed for several days.

Applications of Alum Crystallization:

- Water purification

- Dye manufacturing

- Medical applications (e.g., styptic pencils)

Chemical Crystallization

Chemical crystallization is a versatile method for purifying compounds or synthesizing materials in industries such as pharmaceuticals, petrochemicals, and food production.

Types of Chemical Crystallization:

- Cooling Crystallization: Common for thermally sensitive substances.

- Evaporative Crystallization: Used for substances stable at elevated temperatures.

- Reactive Crystallization: Combines two reactants to produce a crystallizable compound.

Industrial Applications:

- Drug formulation

- Fertilizer production

- Sugar refinement

Optimizing Chemical Crystallization:

- Control temperature gradients to avoid unwanted nucleation.

- Use additives to modify crystal shape and size.

Copper Sulphate Crystallization

Copper sulphate, known for its vibrant blue crystals, is an essential chemical used in agriculture, electroplating, and laboratory experiments.

Process of Copper Sulphate Crystallization:

- Dissolve Copper Sulphate: Heat water and dissolve copper sulphate until saturated.

- Filter the Solution: Remove impurities to ensure pure crystal growth.

- Allow Crystals to Form: Leave the solution to cool and evaporate naturally.

- Harvest Crystals: Collect and dry the formed crystals.

Applications of Copper Sulphate Crystals:

- Fungicides and pesticides

- Electroplating of metals

- Analytical chemistry

Crystallization of Salt

Salt crystallization is one of the oldest and most important industrial processes, essential for food preservation, seasoning, and chemical production.

Salt Crystallization Methods:

- Solar Evaporation: Uses sunlight to evaporate seawater, leaving salt crystals behind.

- Vacuum Evaporation: Accelerates evaporation under reduced pressure.

- Rock Salt Mining: Extracts and purifies salt from underground deposits.

Challenges in Salt Crystallization:

- Impurities affecting crystal quality

- Environmental considerations in salt extraction

Comparison of Crystallization Processes

| Parameter | Alum | Chemical | Copper Sulphate | Salt |

|---|---|---|---|---|

| Primary Method | Cooling/Evaporation | Cooling/Evaporation | Cooling | Evaporation |

| Industrial Applications | Water treatment | Pharmaceuticals | Electroplating | Food industry |

| Time Required | Days | Varies | Days | Weeks |

Applications and Industries Benefiting from Crystallization

- Food Industry: Sugar, salt, and flavoring agents.

- Pharmaceuticals: High-purity drugs and excipients.

- Mining: Separation of valuable minerals.

- Water Treatment: Purification using crystallized alum.

Tips for Successful Crystallization

- Maintain Purity: Filter solutions to remove contaminants.

- Use Seed Crystals: Ensure consistent growth.

- Control Environment: Stable temperature and minimal vibrations are critical.

Why Crystallization Matters

Crystallization is not just a scientific marvel but also a practical technique with transformative applications in multiple industries. Whether you’re a scientist, engineer, or enthusiast, mastering this process opens the door to innovation and discovery.

Frequently asked questions (FAQs)

1. What is crystallization and how does it work?

Crystallization is a process where a solid forms from a liquid or gas, creating a highly ordered structure known as a crystal. This occurs when a solution becomes supersaturated, causing the solute to form crystals as the solution cools or evaporates.

2. What are the different types of crystallization?

The main types of crystallization are:

- Cooling Crystallization: Occurs as the temperature of a solution decreases.

- Evaporative Crystallization: Occurs when the solvent evaporates, leaving behind the solute.

- Reactive Crystallization: Formed through a chemical reaction.

- Antisolvent Crystallization: Uses a non-solvent to precipitate a solute.

3. What are the applications of alum crystallization?

Alum crystallization is widely used in water purification, leather tanning, dye manufacturing, and cosmetics (styptic pencils). It’s also used in the textile industry to fix dyes.

4. What industries use chemical crystallization?

Chemical crystallization is essential in the pharmaceutical, food processing, petrochemical, and mining industries for producing high-purity chemicals, drugs, sugars, and separating minerals.

5. How do copper sulphate crystals form?

Copper sulphate crystals are formed by dissolving copper sulphate in hot water until saturation is reached, then cooling the solution slowly or allowing it to evaporate. Seed crystals may also be used to promote crystal growth.

6. What is the crystallization process for salt?

Salt crystallization can occur through solar evaporation of seawater, vacuum evaporation, or rock salt mining. The most common method involves evaporating seawater until the dissolved salt crystallizes.

7. How can you make alum crystals at home?

To make alum crystals at home, dissolve alum powder in hot water to create a saturated solution, then allow it to cool slowly, optionally adding a seed crystal to promote crystallization.

8. What factors influence the size of crystals?

The size of crystals is influenced by temperature, concentration of the solution, rate of cooling or evaporation, and the presence of impurities. Slow cooling typically results in larger crystals.

9. How long does crystallization take?

The time it takes for crystallization depends on factors like the type of substance, the temperature, and the method used. Alum and copper sulphate crystals can form in a few days, while salt may take weeks.

10. What is the difference between crystallization and precipitation?

Crystallization involves the formation of highly ordered, well-defined crystals, whereas precipitation results in the formation of an amorphous solid from a solution. Crystallization is a more controlled and specific process.

11. Can crystallization be used for purification?

Yes, crystallization is an effective method for purifying substances. By selectively crystallizing a solute, impurities that are not soluble can be removed, leaving behind a pure crystal form.

12. What are the common challenges in salt crystallization?

Some challenges in salt crystallization include the removal of impurities, controlling the rate of evaporation, and environmental considerations, especially in solar evaporation processes.

13. What are the benefits of chemical crystallization in pharmaceutical production?

Chemical crystallization ensures the production of pure, consistent, and high-quality active pharmaceutical ingredients (APIs). It’s vital for the production of drugs, ensuring proper dosing and stability.

14. Can crystallization be done without heat?

Yes, crystallization can occur without heat, especially in evaporative crystallization, where solvent evaporation is facilitated by air exposure rather than heating. Cooling crystallization is another example that doesn’t require heat.

15. What are the key factors for successful crystallization?

Successful crystallization depends on:

- The correct temperature and concentration

- Using seed crystals to promote uniform crystal growth

- Proper solvent selection

- Controlled evaporation or cooling rate

Conclusion

Crystallization is an indispensable process, underpinning advancements in industries from pharmaceuticals to agriculture. By understanding and implementing effective crystallization techniques for alum, chemical compounds, copper sulphate, and salt, you can unlock its full potential.

For more in-depth resources and updates on the latest industrial techniques, visit EngiTech today. Stay informed and lead the way in crystallization technology!