Expert Guide to Conveyor Belt Types and Systems

Conveyor belts and systems are vital in various industries, enabling efficient material handling and transportation. In this comprehensive guide, I’ll explore the different types of conveyor belts and systems, including rubber conveyor belt types, incline conveyor belt types, and more. I’ll provide practical insights to help you understand and choose the right conveyor system for your needs. Let’s dive into the details and understand how these systems can optimize your operations.

What Are Conveyor Belts and Their Importance?

Conveyor belts transport materials and objects efficiently, moving them from one location to another. They are essential in manufacturing, mining, logistics, and other sectors, streamlining operations and improving productivity. The choice of conveyor belt type depends on the specific application, material characteristics, and environmental conditions.

Types of Conveyor Belts

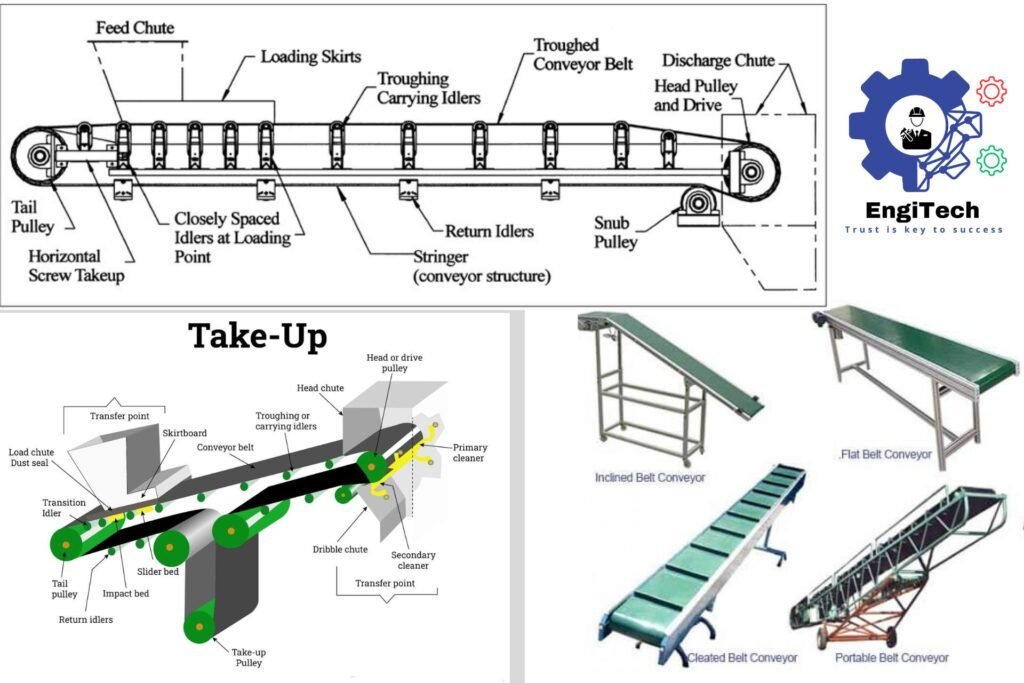

1. Flat Belt Conveyors

Flat belt conveyors are the most widely used type, ideal for transporting items within facilities. They consist of a continuous, flat belt running over rollers and a metal bed, making them versatile for various applications, from manufacturing to packaging.

2. Modular Belt Conveyors

Modular belt conveyors use interlocking plastic or metal modules instead of a continuous flexible belt. They handle sharp, abrasive materials and are popular in food processing, packaging, and automotive industries due to their ease of cleaning and maintenance.

3. Cleated Belt Conveyors

Cleated belt conveyors feature raised sections (cleats) that prevent materials from sliding during transport, especially on inclines or declines. The cleats come in different shapes, such as T-shaped, V-shaped, and U-shaped, and help keep materials in place.

4. Incline/Decline Belt Conveyors

Incline/decline belt conveyors move materials up or down a slope. These conveyors use belts with a textured surface or cleats to prevent slipping, making them ideal for industries that require elevation changes, such as food processing and construction.

5. Roller Bed Belt Conveyors

Roller bed belt conveyors reduce friction by using rollers to support the belt and load. They are suitable for transporting heavy items and are commonly used in warehouses and distribution centers.

6. Curved Belt Conveyors

Curved belt conveyors navigate corners and curves within a facility, maximizing floor space and allowing flexible layout designs. They can be flat or modular, depending on the specific application.

7. Specialty Conveyor Belts

Specialty conveyor belts include magnetic belts, vacuum belts, and high-temperature belts. Magnetic belts transport metal items, vacuum belts hold delicate items in place, and high-temperature belts withstand extreme heat, used in baking and manufacturing.

Types of Conveyor Systems

1. Gravity Conveyor Systems

Gravity conveyors rely on gravity to move items and are cost-effective and simple to use. They include roller and skate wheel conveyors and are ideal for applications where items can roll or slide.

2. Powered Roller Conveyors

Powered roller conveyors use motorized rollers to move items, handling heavier loads efficiently. They are commonly used in sorting, packaging, and assembly lines.

3. Chain Conveyors

Chain conveyors use chains to move products, making them durable and suitable for heavy items. They are often used in automotive and manufacturing industries for transporting parts and assemblies.

4. Overhead Conveyors

Overhead conveyors are suspended from the ceiling, saving floor space. They transport items overhead, ideal for painting, assembly, and other processes where space efficiency is crucial.

5. Pneumatic Conveyors

Pneumatic conveyors use air pressure to move materials through pipelines, making them ideal for transporting powders, granules, and other small items in industries like pharmaceuticals and food processing.

Rubber Conveyor Belt Types

Rubber conveyor belts are popular due to their durability and versatility. The main types include:

- General-purpose rubber belts: Suitable for general material handling across various industries.

- Heat-resistant belts: Designed to withstand high temperatures, ideal for hot materials.

- Oil-resistant belts: Used in environments where oil and grease are present, such as recycling plants.

- Food-grade belts: Made from non-toxic materials, perfect for food processing and handling.

- Heavy-duty belts: Built for handling heavy and abrasive materials, common in mining and construction.

Incline Conveyor Belt Types

Incline conveyor belts come in several types, depending on the application:

- Standard incline belts: Feature a smooth surface, used for general incline transport.

- Cleated incline belts: Equipped with cleats to prevent material rollback, suitable for loose items.

- Rough-top belts: Have a textured surface for grip, used for transporting packaged goods.

Belt Conveyor Roller Types

Rollers are crucial components in belt conveyors, supporting the belt and load. The main types include:

- Troughing rollers: Create a trough shape on the carrying side, increasing load capacity.

- Return rollers: Support the belt on the return side and maintain tension.

- Impact rollers: Absorb impact at loading points, protecting the belt.

- Guide rollers: Keep the belt aligned, preventing mistracking.

Types of Conveyor Belt Lacing

Conveyor belt lacing connects the ends of a conveyor belt. The main types include:

- Mechanical fasteners: Quick and easy metal or plastic lacing for belt repairs.

- Vulcanized splicing: A heat process that creates a strong, seamless joint.

- Hinge lacing: Allows easy opening of the belt for cleaning or maintenance.

Different Types of Conveyor Belts in Industry

Various industries use specific conveyor belts tailored to their needs:

- Mining: Heavy-duty belts for transporting ores and minerals.

- Food processing: Food-grade belts for handling and processing food items.

- Manufacturing: Flat and modular belts for assembly lines.

- Logistics: Roller and belt conveyors for sorting and transporting packages.

- Pharmaceuticals: Hygienic belts to prevent contamination.

Conclusion

Understanding the different types of conveyor belts and systems is crucial for selecting the right equipment for your needs. Whether you need a simple gravity conveyor or a complex modular belt system, choosing the appropriate conveyor ensures smooth and efficient operations. This guide has covered various conveyor types, components, and applications, helping you make informed decisions for your industrial setup.

For more detailed information on conveyor belts and systems, visit EngiTech.in. Stay updated on the latest advancements and best practices in the field!