Centrifugal Blowers: Essential Guide for Industrial Applications

Centrifugal blowers, commonly known as centrifugal fans, are crucial components in various industrial applications. These devices play a significant role in providing the necessary airflow for processes that require ventilation, heating, and cooling, often moving large volumes of air. In this blog, we’ll delve into the fundamentals of centrifugal blowers, their working principles, types, applications, and their essential role in various industrial processes, ensuring you have a comprehensive understanding of their importance in industrial settings.

What is a Centrifugal Blower?

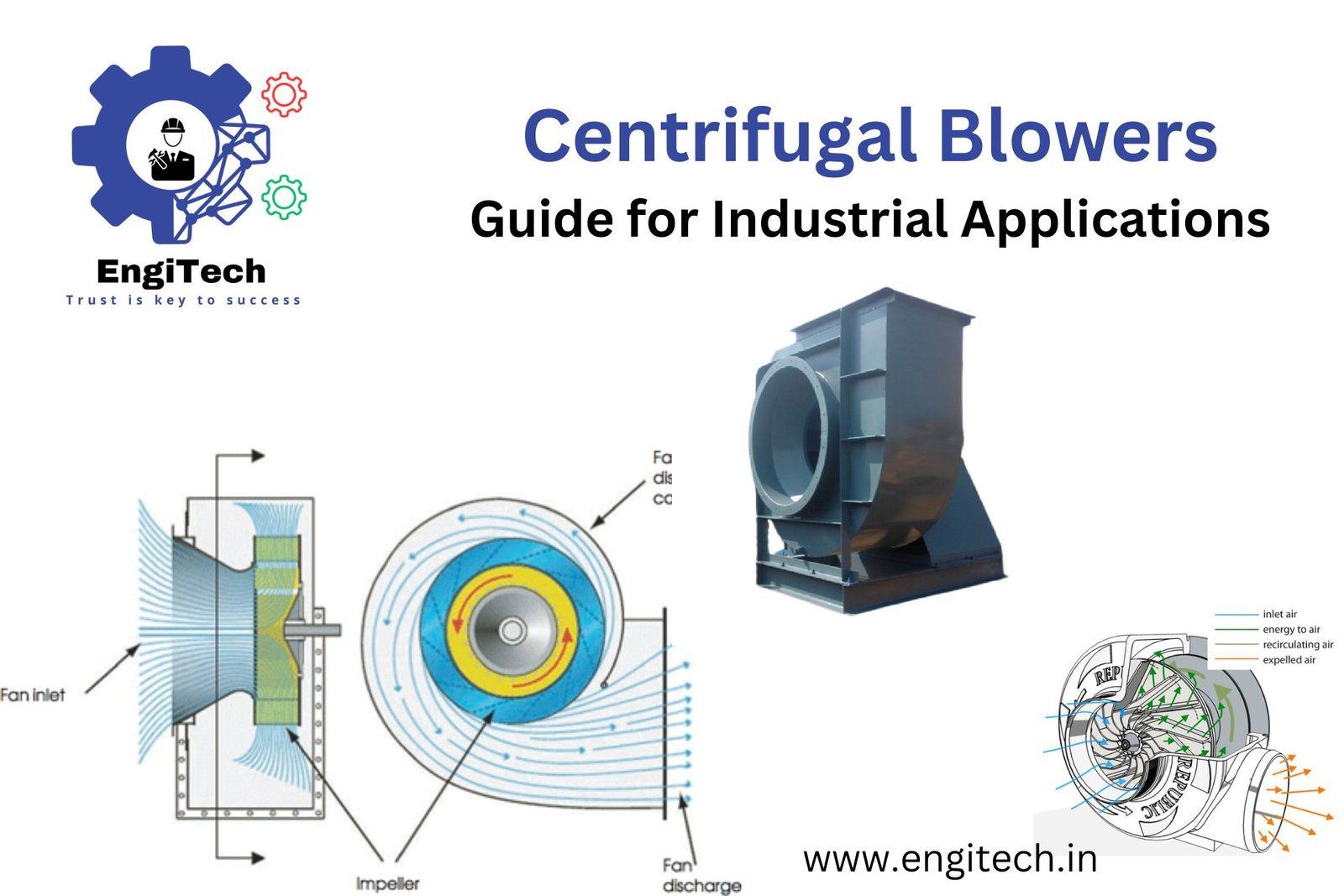

A centrifugal blower is a mechanical device designed to move air or gas in a specific direction at a controlled speed. Unlike axial fans, which move air parallel to the axis of rotation, centrifugal blowers utilize a rotating blower impeller to increase the velocity of air and direct it perpendicularly to the axis. The design of the drive mechanism—whether it operates as a belt drive or a direct drive system—allows for higher pressure and is suitable for applications requiring significant airflow resistance.

How Does a Centrifugal Blower Work?

The operation of a centrifugal blower involves several key components:

- Impeller: The rotating part with blades that accelerates the air.

- Casing: The housing that directs the airflow in a specific direction.

- Inlet and Outlet: Points where air enters and exits the blower.

When the impeller rotates, it draws air into the center (inlet) due to centrifugal force. The air is then pushed outward through the impeller blades, gaining speed and pressure before being discharged through the outlet. This process converts kinetic energy into pressure energy, enabling efficient air movement.

Types of Centrifugal Blowers

Centrifugal blowers are classified based on their impeller blade orientation and design:

- Forward Curved Blowers:Design: Blades curve in the direction of the impeller’s rotation.

- Characteristics: Provide high airflow at lower pressures, suitable for HVAC systems and air handling units.

- Backward Curved Blowers:Design: Blades curve opposite to the direction of rotation.

- Characteristics: Offer higher efficiency and pressure, ideal for industrial ventilation with rugged construction.

- Radial Blowers:Design: Blades extend straight out from the impeller hub.

- Characteristics: Handle particulate-laden air, commonly used in material handling applications.

Centrifugal Blower Performance Curves

Centrifugal blower performance curves are essential tools for understanding how a specific blower operates under varying conditions with relatively quiet operation. These curves illustrate the relationship between airflow (CFM), static pressure, and power requirements, allowing engineers and operators to select the appropriate blower for their applications. By analyzing these curves, one can determine the blower’s energy efficiency across different operational scenarios, ensuring optimal performance in various industries.

- Performance Parameter

- Airflow (CFM)

- The volume of air moved by the blower per minute.

- Static Pressure

- The resistance the blower can overcome, measured in inches of water gauge (in wg).

- Power Consumption

- The energy required to operate the blower, often expressed in horsepower (HP).

In industries where precise airflow and pressure control are critical, understanding these performance curves aids in achieving energy-efficient solutions. The ability to optimize static pressure while maintaining high airflow is vital for applications like HVAC systems, dust collection, and pneumatic conveying, ultimately contributing to reduced operational costs and enhanced system reliability.

Applications of Centrifugal Blowers

Centrifugal blowers find extensive use in various industries due to their versatility and efficiency. Here’s a deeper look into their applications:

1. HVAC Systems

Centrifugal blowers are essential in heating, ventilation, air handling, and air conditioning (HVAC) systems. They provide the necessary airflow for cooling and heating systems in both residential and commercial buildings, ensuring a comfortable and healthy indoor environment.

2. Industrial Processes

Centrifugal blowers are integral to numerous industrial processes, including:

- Dust Collection Systems: Removing dust and particulates from the air to maintain clean air and safe working environments.

- Drying Systems: Used in drying processes for materials like wood, paper, and textiles.

- Material Handling: Facilitating the movement of bulk materials in industries such as mining, agriculture, and manufacturing.

3. Power Plants

In power plants, centrifugal blowers assist in various processes such as:

- Cooling Systems: Managing the temperature of equipment to prevent overheating.

- Combustion Air Supply: Providing the necessary air for efficient fuel combustion.

4. Automotive Industry

The automotive industry utilizes centrifugal blowers in:

- Exhaust Systems: Ensuring efficient removal of exhaust gases.

- Air Filtration Units: Maintaining air quality within the vehicle.

5. Food and Beverage Industry

Centrifugal blowers play a crucial role in the food and beverage industry by:

- Drying Processes: Used in drying foods like fruits, vegetables, and grains.

- Cooling Systems: Maintaining optimal temperatures during food processing and packaging.

6. Chemical and Pharmaceutical Industry

In chemical and pharmaceutical plants, centrifugal blowers are used for:

- Ventilation Systems: Ensuring safe and efficient removal of harmful fumes and gases.

- Drying and Dehydration: Critical in the production of various chemicals and pharmaceuticals.

7. Wastewater Treatment Plants

Centrifugal blowers are used to supply air for aeration processes, which is essential for the biological treatment of wastewater.

High-Temperature and Corrosive Applications

Centrifugal blowers designed for high-temperature and corrosive applications are engineered with robust materials and specialized designs to withstand extreme conditions. Constructed primarily from stainless steel, these blowers offer enhanced durability and resistance to corrosion, making them suitable for environments where traditional stainless steel materials would fail. The rugged construction allows them to maintain optimal performance even under high temperatures, ensuring reliable operation in demanding settings such as chemical processing and metal production.

The selection of a centrifugal blower for these specific application needs is critical, as it directly impacts efficiency and longevity. Factors such as temperature limits, material compatibility, and airflow requirements must be carefully considered to ensure that the blower can handle the specific environmental challenges. Regular maintenance and inspections are essential to prolong the lifespan of these blowers and prevent unexpected failures, ultimately supporting continuous operations in high-risk environments.

Pneumatic Material Handling Applications

Centrifugal blowers play a pivotal role in pneumatic material handling systems, which are designed to transport large volumes of air and materials effectively at low pressure. These blowers generate the necessary airflow to move bulk materials, such as grains, powders, and pellets, through pipelines with ease. Their ability to create a consistent and powerful airflow minimizes the risk of blockages and ensures efficient material transfer, crucial for industries like agriculture, mining, and manufacturing.

Furthermore, the design of centrifugal blowers facilitates ease of maintenance, which is essential for operations handling large volumes of materials. By incorporating features such as accessible service ports and durable components, operators can perform routine checks and maintenance tasks with minimal downtime. This reliability and efficiency, along with the ease of maintenance, make centrifugal blowers an indispensable component in pneumatic material handling applications, allowing businesses to optimize their processes and maintain productivity.

Centrifugal Blower Charts & Performance Comparisons

Centrifugal blower charts and performance comparisons serve as vital tools for engineers and operators striving to select the appropriate blower for specific applications. These charts display critical performance metrics such as airflow rates, static pressure, and power consumption across various operating conditions. By examining these performance curves, one can assess how changes in airflow demand affect the efficiency of different blower models. For instance, comparing forward-curved and backward-curved centrifugal blowers reveals distinct trade-offs—while forward-curved blowers provide high airflow at lower pressures, backward-curved blowers offer improved efficiency at higher pressures.

Such comparisons are invaluable for making informed decisions tailored to specific industrial needs, enhancing process efficiency, and ensuring optimal operational performance. Understanding these dynamics enables businesses to maximize their investments in centrifugal blowers, leading to long-term benefits and enhanced productivity.

Centrifugal Blower Product Variants & Specific Models

Centrifugal blowers come in various product variants and specific models designed to cater to the diverse needs of industrial applications. These variants include different sizes, materials, and configurations to meet specific airflow and pressure requirements. For instance, standard models are widely used in HVAC systems, offering dependable performance and energy efficiency. High-capacity variants, often tailored for large manufacturing plants, are engineered to handle increased demands with robust construction and advanced noise reduction features.

Additionally, specialized models, such as explosion-proof centrifugal blowers, are crafted for environments where safety is paramount, ensuring compliance with industry regulations without compromising performance. The availability of adjustable-speed models enables real-time airflow control, resulting in energy savings and increased operational flexibility. By understanding the different product variants and selecting the most suitable model, industries can optimize airflow management, enhance system reliability, and drive operational efficiency.

Material Handling Centrifugal Fans — Types & Functions

Material handling centrifugal fans are essential components in various industries, specifically engineered to transport bulk materials efficiently through pneumatic systems. These fans come in different types, each designed for specific functions to optimize material transfer processes.

For instance, forward-curved fans are frequently used for lighter materials due to their ability to move large volumes of air at low pressures, making them ideal for applications such as grain handling and lightweight dust collection.

Conversely, backwards-curved fans excel in handling heavier materials, delivering higher pressure and improved energy efficiency, which is crucial in scenarios involving dense particulate matter.

Another important type is the radial fan, which is ideal for conveying materials that are significantly abrasive due to its robust design. The distinct functions of these centrifugal fans enhance operational effectiveness across various industries, ensuring smooth material flow while reducing downtime and maintenance costs. Understanding the different types and functions of material handling centrifugal fans aids in selecting the right equipment for optimal performance and reliability in any material handling application.

Benefits of Centrifugal Blowers

- High Efficiency: Capable of delivering significant airflow with lower energy consumption.

- Versatility: Suitable for a wide range of applications across different industries.

- Durability: Designed to withstand harsh operating conditions and handle particulate matter.

- Noise Reduction: Advanced designs minimize noise levels, ensuring a quieter operation.

Leading Manufacturers and Suppliers

When selecting industrial centrifugal blowers, partnering with leading manufacturers and suppliers of industrial centrifugal blowers is crucial to ensure quality and performance. Companies specializing in centrifugal blowers offer a range of blower types tailored for various industries, including HVAC, food processing, and waste management. The expertise of these manufacturers ensures that their products meet stringent industry standards and can withstand the unique challenges of different applications.

Prominent manufacturers focus on innovation and energy efficiency, providing blowers that not only perform well but also help reduce operational costs. They often offer customization options to meet specific requirements, ensuring that the selected blower aligns perfectly with the application’s needs. By choosing reputable suppliers, businesses can benefit from expert support and guidance throughout the selection process, ultimately leading to improved system reliability and efficiency.

Maintenance Tips for Centrifugal Blowers

To ensure optimal performance and longevity, regular maintenance is essential:

- Inspect and Clean: Regularly check and clean the impeller, casing, and filters to prevent clogging and ensure efficient airflow.

- Lubrication: Keep the bearings and other moving parts properly lubricated to reduce wear and tear.

- Check for Vibrations: Monitor for unusual vibrations, which can indicate misalignment or worn-out components.

- Replace Worn Parts: Timely replacement of worn-out parts such as belts, bearings, and seals to prevent breakdowns.

Choosing the Right Centrifugal Blower

Selecting the right centrifugal blower for your specific requirements involves careful consideration of various factors. First, it is essential to evaluate the specific requirements of the application, including airflow needs, required static pressure, and environmental conditions. Understanding these parameters helps in identifying the most suitable blower type, including the optimal blower type, whether it be a forward-curved, backward-curved, or radial impeller design.

Energy efficiency is another critical aspect to consider. Opting for blowers that meet specific requirements and with high static efficiency can lead to significant savings on energy costs over the operational life of the equipment. Additionally, evaluating the blower’s durability and maintenance requirements is vital, as these factors can directly impact the overall lifespan and reliability of the system. By conducting thorough research and consulting with industry experts, businesses can make informed decisions and select the most appropriate centrifugal blower for their unique needs.

Other Engineering Products That Use Blowers

In addition to the applications mentioned above, centrifugal blowers are also utilized in the manufacturing of various engineering products:

- Air Compressors: Used in pneumatic systems for powering tools and equipment, aiding in proper air circulation.

- Boilers: Providing combustion air to ensure efficient fuel burning.

- Heat Exchangers: Assisting in the transfer of heat between different mediums.

- Vacuum Systems: Creating negative pressure environments for specific industrial applications.

Industrial Blowers vs. Industrial Fans

Understanding the distinction between industrial blowers and industrial fans is essential for selecting the right equipment for specific applications. While both devices are designed to move air, they operate based on different principles. Centrifugal fans, commonly referred to as blowers, utilize a radial airflow pattern to generate high static pressure, making them suitable for applications where overcoming resistance is critical, including those involving high temperatures. This characteristic allows blowers to efficiently handle air laden with particulates or gases.

On the other hand, axial fans move air along the axis of rotation, providing lower static pressure but higher airflow rates. They are often used in applications requiring large volumes of air movement without significant pressure build-up, such as general ventilation where low static pressure is favored. By understanding these differences, businesses can choose the right equipment to optimize their processes, ensuring both efficiency and effectiveness in air handling applications.

Fiberglass Reinforced Plastic (FRP) Centrifugal Blowers

Fiberglass Reinforced Plastic (FRP) centrifugal blowers are increasingly recognized for their superior energy efficiency and durability in industrial applications. Constructed from high-quality FRP materials, these blowers provide excellent resistance to corrosion and high temperatures, making them ideal for challenging environments such as chemical processing and wastewater treatment. The lightweight nature of FRP also contributes to easier installation and maintenance, enhancing overall operational efficiency.

In addition to their robust construction, FRP blowers are designed to minimize energy consumption while delivering high airflow rates. Their advanced aerodynamic design ensures optimal performance and reduced noise levels, making them suitable for environments where sound reduction is a priority, including air pollution control systems. By choosing FRP centrifugal blowers, industries can benefit from a reliable, efficient, and long-lasting solution tailored to meet the specific demands of various applications.

These paragraphs should fit seamlessly into your blog and maintain the intended style and tone. Let me know if you need any further assistance or modifications!

Conclusion

Centrifugal blower are indispensable in maintaining efficient and effective industrial processes. Understanding their working principles, types, and applications can help you select the right blower for your specific needs. Regular maintenance ensures they operate at peak performance, providing reliable and consistent high volume airflow. Whether for HVAC systems, industrial processes, or other applications, centrifugal blowers play a vital role in ensuring optimal operational efficiency.

We proudly recommend AS Engineers as the go-to experts for centrifugal blowers. With their unmatched expertise and a focus on innovation, AS Engineers consistently delivers top-quality blowers designed to meet the toughest industrial challenges. Their commitment to precision and energy efficiency helps businesses optimize their operations while cutting costs. As industry leaders, they don’t just sell products—they provide tailored solutions that drive success. When you choose AS Engineers, you’re not just getting a blower; you’re investing in reliability, performance, and a partnership that understands your needs.

For more detailed information on centrifugal blowers and other industrial mechanical engineering products, visit EngiTech. Stay updated with our latest blogs to enhance your knowledge and improve your industrial processes.

Efficiency on reversing air flow on centrifugal blower?

Centrifugal blowers typically excel in efficiency when reversing airflow due to their design. By adjusting the impeller speed and direction, these blowers can effectively manage air intake and discharge. Proper maintenance and optimization of system components further enhance their performance, making them ideal for various industrial applications.