The Comprehensive Guide to Cartesian Robots: Everything You Need to Know

In the world of automation, Cartesian robots are leading the charge, bringing precision, reliability, and efficiency to countless industries. Whether you’re new to robotics or an experienced engineer looking to deepen your knowledge, understanding how these robots work is essential. In this guide, we’ll explore everything you need to know about Cartesian robots, from their structure and benefits to their practical applications in industrial settings.

By the end of this post, you’ll have a complete understanding of why Cartesian robots are the go-to solution for automated tasks and how they compare to other types of robots, ensuring you can make informed decisions for your business or engineering needs.

Table of Contents

What Are Cartesian Robots?

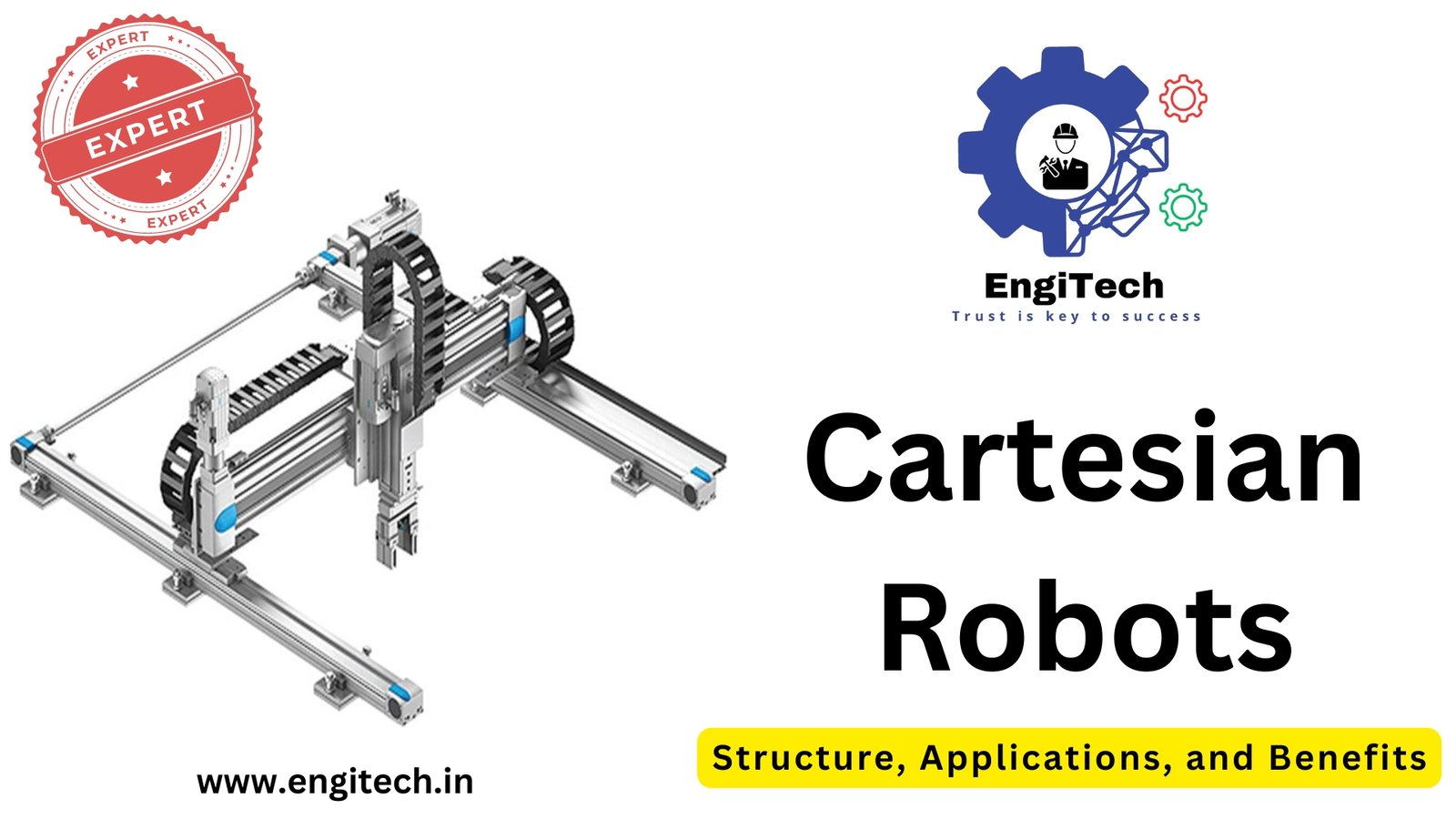

A Cartesian robot, also known as a linear robot, operates on three linear axes (X, Y, and Z), following a Cartesian coordinate system. This means that the robot moves in straight lines along these three axes, which makes them ideal for applications requiring precision and repeatability.

The Basic Structure of a Cartesian Robot

The fundamental structure of a Cartesian robot includes three perpendicular arms or axes, typically referred to as the X, Y, and Z axes. Each axis is responsible for motion along a straight line, allowing the robot to move with high accuracy in three-dimensional space. Cartesian robots often feature:

- Linear Actuators: These are the driving mechanisms responsible for moving along the X, Y, and Z axes.

- End-Effector: This is the tool or attachment that interacts with the workpiece. It can range from simple grippers to complex tools.

- Control Systems: A programmable controller dictates the robot’s movements and sequences, allowing for automation of repetitive tasks.

This simple, robust design allows Cartesian robots to excel in tasks where straight-line movement is required, such as pick-and-place operations, assembly, and material handling.

Why Use Cartesian Robots?

Cartesian robots offer several advantages that make them an attractive choice for various industries. These include:

- High Precision and Repeatability: Since they operate along fixed axes, Cartesian robots provide superior accuracy, making them ideal for precision tasks like assembly and inspection.

- Ease of Programming: The use of a straightforward coordinate system means that Cartesian robots are easier to program compared to other robots that may require complex algorithms for movement.

- Scalability: Cartesian robots can be scaled to fit a wide range of applications. They can be as small as a desktop machine or large enough to work on industrial assembly lines.

- Cost-Effectiveness: Due to their simple design, Cartesian robots are generally less expensive to manufacture and maintain compared to other types of robots.

- Load Capacity: Cartesian robots can handle a significant amount of weight, making them ideal for tasks like lifting and transporting heavy materials.

Applications of Cartesian Robots

Thanks to their versatility, Cartesian robots are used across a wide variety of industries. Here are some common applications:

Pick-and-Place Operations

One of the most common uses of Cartesian robots is in pick-and-place tasks. These robots excel at moving items from one location to another with precision and speed, making them essential in packaging, assembly, and material handling.

CNC Machining

In industries like automotive and aerospace, Cartesian robots are often used in CNC machining. Their linear motion allows them to follow precise cutting paths, ensuring that components are manufactured with tight tolerances.

3D Printing

Many 3D printers utilize a Cartesian coordinate system to move the print head and build platforms. This setup allows for precise layer deposition, resulting in high-quality printed objects.

Inspection and Quality Control

Cartesian robots are also used in automated inspection processes, where they can move across products to measure dimensions or check for defects with accuracy and repeatability.

Comparing Cartesian Robots to Other Robots

When choosing the right robot for your application, it’s essential to understand how Cartesian robots compare to other types. Here’s a quick comparison:

Cartesian Robots vs. SCARA Robots

- Cartesian Robots: Move in straight lines along three axes, ideal for tasks that require precision and repeatability in 3D space.

- SCARA Robots: These robots are more flexible, moving in arcs and curves. They are faster but may lack the precision required for some tasks.

Cartesian Robots vs. Articulated Robots

- Cartesian Robots: Best for applications that require linear motion and a simple design.

- Articulated Robots: These robots have multiple joints, allowing for more complex movements. They are ideal for tasks that require greater flexibility, such as welding or painting.

Cartesian Robots vs. Delta Robots

- Cartesian Robots: Provide stable and controlled movements, making them ideal for heavy lifting and precision work.

- Delta Robots: Known for their speed and agility, delta robots are better suited for fast pick-and-place tasks.

Choosing the Right Cartesian Robot for Your Needs

When selecting a Cartesian robot for your specific application, consider the following factors:

- Payload Capacity: How much weight does the robot need to move? Cartesian robots can handle various payloads, but selecting the right model for your load is crucial.

- Precision: If your task requires high levels of accuracy, ensure that the robot’s specifications meet the precision demands of your project.

- Work Envelope: Consider the size of the area the robot will need to operate in. Cartesian robots can be configured to work in a wide range of sizes, from small desktop setups to large industrial spaces.

- Speed Requirements: If the task requires quick movements, ensure the robot is capable of achieving the necessary speeds without sacrificing precision.

The Future of Cartesian Robots

As automation technology advances, Cartesian robots continue to evolve. With the integration of AI and machine learning, future Cartesian robots will likely become even more autonomous and capable of handling complex tasks with minimal human intervention. Additionally, advancements in materials and control systems will further enhance their efficiency and flexibility, opening up new possibilities in manufacturing, healthcare, and beyond.

How to Optimize a Cartesian Robot for Maximum Efficiency

To get the most out of your Cartesian robot, follow these best practices:

- Regular Maintenance: Keep the robot’s actuators, bearings, and control systems in good condition to prevent breakdowns and ensure smooth operation.

- Proper Calibration: Ensure that the robot is calibrated correctly to maintain accuracy, especially in precision tasks.

- Programming Optimization: Use efficient programming techniques to minimize movement and reduce cycle times, thereby increasing overall productivity.

- Load Balancing: Distribute the workload evenly to prevent overloading the robot and ensure consistent performance.

Frequently asked questions (FAQs) about Cartesian robots:

- What is a Cartesian robot?

- A Cartesian robot operates on three linear axes (X, Y, Z) and follows a Cartesian coordinate system to perform tasks with precision.

- How do Cartesian robots work?

- Cartesian robots move along straight lines across three axes, allowing for highly accurate and repeatable movements in 3D space.

- What are the main applications of Cartesian robots?

- You can use Cartesian robots in pick-and-place operations, CNC machining, 3D printing, and inspection tasks, among other applications.

- Why are Cartesian robots widely used in manufacturing?

- Manufacturers prefer Cartesian robots for their simplicity, accuracy, scalability, and cost-effectiveness in automated processes.

- How accurate are Cartesian robots?

- Cartesian robots provide high precision and repeatability, making them ideal for tasks requiring tight tolerances and consistent accuracy.

- What industries benefit the most from Cartesian robots?

- Cartesian robots are commonly used in industries such as automotive, electronics, packaging, aerospace, and medical device manufacturing.

- What is the difference between Cartesian robots and SCARA robots?

- Cartesian robots move along linear axes, while SCARA robots have flexible, rotational arms, making them better suited for curved or circular motions.

- Can you customize Cartesian robots?

- Yes, you can customize Cartesian robots to fit specific requirements, including payload, speed, and working area.

- What is the typical payload capacity of Cartesian robots?

- Depending on the model, Cartesian robots can handle a wide range of payloads, from light objects to several hundred kilograms.

- How do you program a Cartesian robot?

- You program Cartesian robots using a simple coordinate-based system, which makes them easier to control compared to other robot types.

- How do Cartesian robots improve efficiency in production lines?

- Cartesian robots increase efficiency by automating repetitive tasks, reducing errors, and speeding up production cycles.

- What are the advantages of using Cartesian robots over other robots?

- Cartesian robots offer simpler design, lower cost, easier programming, and better performance for linear motion tasks compared to other types of robots.

- Are Cartesian robots easy to maintain?

- Yes, Cartesian robots are relatively easy to maintain, thanks to their straightforward design and minimal moving parts.

- How do you select the right Cartesian robot for a project?

- You should consider factors like load capacity, precision, speed, and the size of the work area when selecting a Cartesian robot for your needs.

- What are the future trends for Cartesian robots?

- The future of Cartesian robots includes advancements in AI, machine learning, and materials, which will enhance their performance and expand their use in new industries.

Conclusion

Cartesian robots are a crucial component of modern automation, offering unparalleled precision, scalability, and cost-effectiveness. Their simple, robust design makes them ideal for a wide range of industries, from manufacturing and packaging to 3D printing and CNC machining.

If you’re considering implementing Cartesian robots in your operation, now is the perfect time to explore the possibilities. With their growing versatility and future potential, these robots can revolutionize your business, improve efficiency, and reduce costs.

Ready to learn more about how Cartesian robots can enhance your industrial operations? Visit EngiTech for comprehensive resources and the latest innovations in automation technology. Stay ahead of the curve with cutting-edge insights from industry experts.