How Biogas Plants Work & Their Benefits – EngiTech

Biogas has emerged as one of the most promising renewable energy sources of the 21st century, offering both environmental and economic advantages. Whether you’ve heard the term “Gobar Gas Plant,” “Bio Digester,” or simply “Biogas,” the core concept remains the same: harnessing the power of organic waste to produce clean, sustainable fuel. In this comprehensive guide, you’ll discover how biogas plants work & their benefits, explore the intricacies of biogas production, understand different types of biogas systems, and learn practical steps for setting up a biogas home plant—while also figuring out the costs, returns, and real-world applications.

Biogas has grown beyond mere theory—governments, NGOs, and private enterprises worldwide are investing heavily in projects to bring this renewable energy to households, farms, and entire communities. By the end of this article, you will have an advanced understanding of how biogas plants function, what makes them so beneficial, and how you can be part of this green revolution. Let’s dive in.

Table of Contents

1. Understanding Biogas: The Fundamentals

Biogas, often called Gobar Gas or Bio Gas, is essentially a mixture of gases—primarily methane (CH4) and carbon dioxide (CO2)—produced through the breakdown of organic matter in an oxygen-free environment. This process of anaerobic digestion occurs naturally in places like swamps, landfills, and even the stomachs of ruminants like cows.

Defining Biogas Energy

- Biogas Energy refers to the energy harnessed from biogas combustion. Because methane is the primary combustible component, it’s an excellent fuel source that can power cooking stoves, engines, and even electricity generators.

- It serves as a clean alternative to fossil fuels, reducing greenhouse gas emissions and promoting sustainable waste management.

Why Biogas Is Important

- Renewable Resource: Unlike finite resources such as coal and oil, biogas is continually produced as long as organic waste is available.

- Waste Reduction: Biogas production helps manage agricultural, municipal, and even human waste more efficiently.

- Economic Benefits: Local production can reduce dependence on imported fuels, lowering costs and stabilizing energy supplies.

By understanding the fundamentals, you grasp how biogas plants not only offer a sustainable energy solution but also promote circular economies around the world.

2. The Science Behind Biogas Production

Anaerobic Digestion Explained

Anaerobic digestion is a four-step biochemical process:

- Hydrolysis: Complex organic materials—such as carbohydrates, fats, and proteins—are broken down into simpler compounds like sugars, fatty acids, and amino acids.

- Acidogenesis: These simpler compounds are further metabolized by bacteria, producing volatile fatty acids, ammonia, and hydrogen.

- Acetogenesis: The intermediate products are converted into acetic acid, carbon dioxide, and hydrogen.

- Methanogenesis: Specialized methanogenic archaea bacteria then convert acetic acid and hydrogen into biogas—mostly methane and carbon dioxide.

Key Parameters for Optimal Biogas Production

- Temperature: Most biogas plants operate in the mesophilic range (around 35–40°C) or thermophilic range (50–60°C). Maintaining consistent temperature is crucial.

- pH Level: Ideally, the pH should remain between 6.5 and 7.5 for optimal bacterial activity.

- Carbon-to-Nitrogen Ratio (C:N Ratio): Balancing carbon and nitrogen in feedstock ensures bacterial efficiency. Agricultural residues with high carbon content can be mixed with nitrogen-rich manures.

- Retention Time: The duration the feedstock remains inside the digester. In many systems, 20–30 days is common, but it can vary based on the technology.

When these factors align, biogas production is maximized. By understanding the science, plant owners can troubleshoot issues and optimize their system’s efficiency.

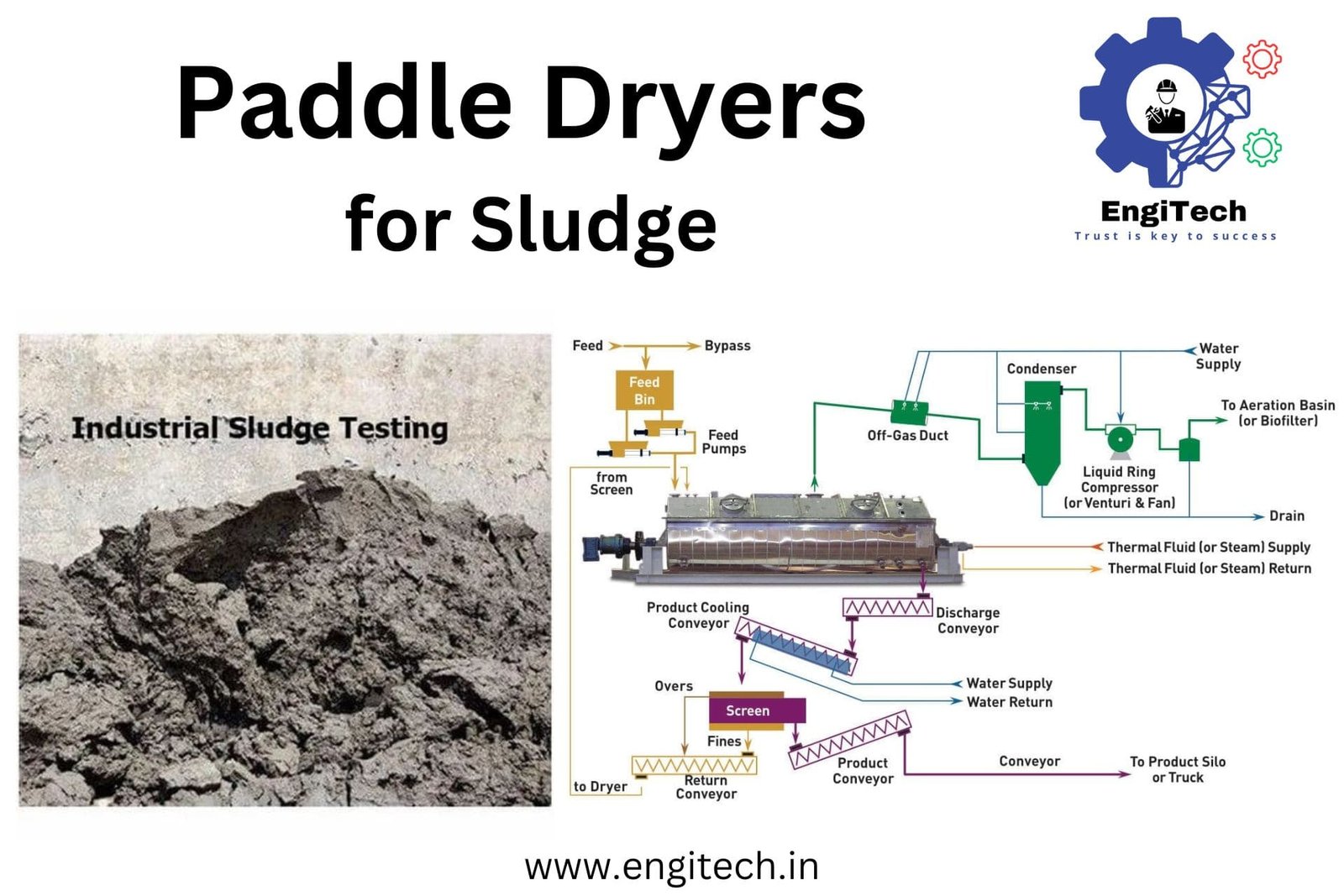

3. Key Components of a Biogas Plant

Although designs can vary—ranging from rudimentary household models to advanced industrial facilities—most biogas plants include the following components:

- Feedstock Input Unit: Where organic waste is loaded, often referred to as an inlet chamber.

- Digester Tank: The airtight container where anaerobic digestion occurs. This can be a concrete chamber, steel tank, or reinforced plastic vessel.

- Gas Holder/Dome: Captures and stores the biogas that is produced. Some systems have a floating drum, while others use a fixed dome.

- Outlet or Slurry Storage: Post-digestion residue, often called “digestate,” is discharged. This nutrient-rich byproduct can be used as fertilizer.

- Piping & Control Mechanisms: Ensures that biogas is transported to stoves or engines, including valves, pressure gauges, and safety devices.

Understanding these parts helps you navigate everything from small Gobar Gas Plant for home use to larger, commercial Bio CNG Plant designs.

4. Major Types of Biogas Plants

Biogas technology has evolved significantly. Below are some popular types of biogas plants, each suited to different scales and requirements.

4.1 Fixed-Dome Biogas Plant

- Design: A fixed dome made of concrete or bricks. The digester is attached to a permanent dome-shaped gas holder.

- Advantages: Durable, low maintenance, cost-effective for long-term use.

- Disadvantages: Gas pressure can vary; construction requires skilled labor.

4.2 Floating Drum Biogas Plant

- Design: Features a movable, inverted drum that floats over the slurry. As gas accumulates, the drum rises.

- Advantages: Consistent gas pressure; easy to check gas levels.

- Disadvantages: Metal drum requires frequent maintenance to prevent rust.

4.3 Balloon or Bag Digester

- Design: Uses flexible plastic or rubber balloons to hold feedstock and gas.

- Advantages: Low-cost; easy to transport and install.

- Disadvantages: Less durable; prone to damage.

4.4 Continuous Stirred Tank Reactor (CSTR)

- Design: Large tank with mechanical or hydraulic stirring. Commonly used in industrial setups.

- Advantages: Efficient mixing ensures consistent biogas output; handles various waste types.

- Disadvantages: Higher initial biogas plant cost; requires advanced technical expertise.

4.5 Two-Stage Biogas Systems

- Design: Separates the hydrolysis and methanogenesis phases into different tanks for optimal conditions.

- Advantages: Higher efficiency and methane yield.

- Disadvantages: More complex, expensive.

Your choice depends on local conditions, the type of feedstock, budget, and the intended scale—be it a Gobar Gas Plant in a rural household or a commercial-scale Bio CNG Plant catering to urban waste management.

5. How to Set Up a Biogas Home Plant

Building a biogas home plant isn’t as daunting as it may sound. With careful planning, the right materials, and some basic technical knowledge, you can create a system that supplies clean cooking fuel while reducing your household waste.

5.1 Assessing Feasibility

- Daily Organic Waste Generation: Do you have enough kitchen scraps, livestock manure, or agricultural residues?

- Available Space: A small yard or designated area for the digester and slurry outlet is needed.

- Climate: Warmer regions are more suitable, though insulation or underground installation can work in colder climates.

- Regulations: Check local laws, permits, or guidelines on setting up a household digester.

5.2 Materials & Tools

- Digester: A prefabricated plastic or concrete chamber.

- Inlet & Outlet Pipes: To load waste and remove digestate.

- Biogas Storage: A fixed dome or a balloon-type holder.

- Piping System to Kitchen: Typically PVC or rubber tubing, plus valves and burners.

5.3 Construction & Installation Steps

- Digging and Preparing: Excavate a pit if opting for an underground model. Ensure the site has good drainage.

- Installing Digester: Place the digester, making sure it’s airtight. Leaks dramatically reduce efficiency.

- Connecting Inlet & Outlet: Ensure a seamless flow of waste in and slurry out.

- Initial Feed: Start with a slurry mix of manure and water to activate the bacteria.

- Monitoring & Maintenance: Check daily for gas leaks, pH, and temperature. A well-sealed system can generate biogas in about 2–3 weeks.

5.4 Safety Measures

- Pressure Release Valve: Install to prevent overpressure in the system.

- Regular Leak Checks: Use soapy water to test connections.

- Ventilation: Ensure the kitchen or stove area is well-ventilated.

If you take these steps seriously, your biogas home plant will be a reliable source of clean energy for cooking and even heating.

6. Biogas Plant Cost & ROI

Cost is a major factor for anyone contemplating a biogas plant, be it a large-scale industrial setup or a simple Gobar Gas Plant for home use. Understanding both the initial outlay and long-term returns helps make an informed decision.

6.1 Initial Investment Factors

- Type & Size of the Plant: A small household digester can cost a few hundred dollars, whereas industrial plants run into the tens or even hundreds of thousands.

- Construction Materials: Concrete and steel-based systems often have higher costs than simple plastic digesters.

- Location: Labor costs, local material availability, and site preparation requirements can vary.

- Auxiliary Equipment: Stirrers, heating systems, or Bio CNG Plant upgradation units can significantly inflate costs.

6.2 Operational & Maintenance Costs

- Feedstock Logistics: Transporting agricultural waste or manure can add recurring costs.

- Skilled Personnel: Larger plants may need technicians and engineers.

- Maintenance & Repairs: Regular checks and part replacements for valves, pipes, or gas holders.

6.3 Return on Investment (ROI)

- Energy Savings: Biogas can substantially lower electricity or LPG bills.

- Fertilizer Value: The digestate byproduct can reduce or eliminate the need for chemical fertilizers.

- Carbon Credits: In some regions, you can earn incentives or sell carbon offsets for producing renewable energy.

Many owners see a payback period of 3–5 years for moderate-scale plants, though the exact timeline varies. Overall, investing in a biogas plant can be financially appealing, especially when factoring in environmental benefits and energy self-reliance.

7. Environmental Impact & Sustainability Benefits

One of the primary drivers for adopting biogas energy is its considerable environmental advantages. In an era dominated by concerns over climate change and waste pollution, biogas emerges as a holistic solution.

7.1 Reduction in Greenhouse Gas Emissions

When organic waste decomposes in open landfills, it releases methane directly into the atmosphere—a potent greenhouse gas. Capturing this methane to produce biogas not only prevents harmful emissions but also turns them into useful energy. According to the United Nations Environment Programme (UNEP), efficient biogas systems can reduce up to 50–70% of greenhouse gas emissions compared to traditional waste management practices.

7.2 Waste Management & Resource Efficiency

- Less Landfill Overload: Diverting organic waste to biogas plants relieves pressure on landfills, reducing leachate and soil contamination.

- Nutrient Recycling: The leftover digestate is nutrient-rich, returning essential elements to the soil and promoting sustainable agriculture.

- Energy Circularity: Biogas plants close the loop—waste in, energy out, soil amendment back into the land.

7.3 Aligning with Sustainable Development Goals (SDGs)

Biogas contributes to several United Nations SDGs, including:

- SDG 7: Affordable and Clean Energy

- SDG 12: Responsible Consumption and Production

- SDG 13: Climate Action

Such alignment attracts attention from governments, NGOs, and eco-conscious consumers, making biogas an all-around winner for sustainability.

8. Real-World Applications & Biogas Uses

The versatility of biogas extends far beyond just cooking fuel. Thanks to technological advancements, it can be upgraded, compressed, and utilized in diverse applications—ranging from small farms to large-scale municipal projects.

8.1 Household Cooking and Heating

- Biogas Home Plant: Many rural households worldwide use a simple digester to generate gas for daily cooking. This reduces or eliminates the need for firewood, coal, or LPG.

- Winter Heating: In cooler climates, biogas can also supplement or replace heating systems.

8.2 Electricity Generation

- Engine Generators: Biogas can be fed into modified internal combustion engines to produce electricity. Farms and communities thus become energy self-sufficient.

- Microgrids: In remote areas without reliable grid access, biogas-based power plants can form microgrids, improving local energy resilience.

8.3 Vehicle Fuel (Bio CNG & Biogasoline)

- Bio CNG Plant: Upgraded biogas—compressed to high pressure—can serve as Bio CNG, a cleaner alternative to diesel or petrol for vehicles.

- Biogasoline: Research is ongoing to convert biogas to liquid fuels akin to gasoline, potentially reshaping the automotive industry.

8.4 Industrial & Commercial Uses

- Wastewater Treatment: Sewage plants install biogas digesters to treat sludge, reducing disposal costs while generating power.

- Food Processing Industry: Large volumes of organic waste can be converted into energy, offsetting operational costs.

- Agricultural Sector: Livestock farms utilize biogas digesters to manage manure, improving sanitation and reducing odors.

From cooking in a remote village to powering public buses in urban centers, biogas technology showcases remarkable flexibility.

9. Global Perspective: Policies & Innovations

Growing environmental concerns and the global push towards cleaner energy sources have spurred numerous governmental and private-sector initiatives to promote biogas.

9.1 Government Incentives & Regulations

- Feed-in Tariffs (FITs): Many countries offer guaranteed rates for renewable energy producers, including biogas-based electricity.

- Capital Subsidies: Various governments—like India, China, and Germany—provide subsidies for constructing biogas plants, particularly in rural areas.

- Regulatory Support: Streamlined approvals, carbon credit schemes, and renewable energy certificates encourage adoption.

9.2 Technological Advancements

- Advanced Bio Digesters: Improved designs now optimize bacterial activity, achieving higher biogas yields in shorter time frames.

- Hybrid Systems: Some innovators combine solar and biogas systems for a more stable power supply.

- IoT & Automation: Internet-connected sensors allow for real-time monitoring of temperature, pH, and gas production, enhancing efficiency and reducing downtime.

9.3 International Collaborations & Projects

- Paggawa ng Biogas in the Philippines: Community-driven models where government and NGOs cooperate to empower local farmers.

- EWB Biogas Projects: Engineers Without Borders (EWB) often spearhead biogas installations in developing regions to improve sanitation and energy access.

- Ecologic Biogas Initiatives: Organizations emphasizing ecological balance and sustainable resource management, using biogas as a cornerstone technology.

- Guna Biogas Ventures: Tailored solutions that integrate local feedstock types and climatic conditions, championed by specialized NGOs and private firms.

As these policies and innovations spread, biogas continues to solidify its status as a key player in the global shift to renewable energy.

10. Common Challenges & Troubleshooting

Like any technology, biogas plants can face obstacles. However, understanding these challenges upfront helps ensure smoother operation and better results.

10.1 Low or Inconsistent Gas Production

- Insufficient Feedstock: Make sure you’re adding enough organic waste. In some cases, supplement with other carbon-rich materials.

- Temperature Fluctuations: If the digester gets too cold, gas production can drop. Consider insulation or a heating mechanism in cooler climates.

- pH Imbalances: Add buffering agents like lime if the slurry becomes too acidic.

10.2 Leakage & Safety Issues

- Faulty Sealants or Joints: Regularly inspect and replace gaskets and seals.

- Overpressure: Install a pressure release valve and monitor gauges.

- Fire and Explosion Risks: While rare, methane is flammable. Always keep the area well-ventilated and free of sparks.

10.3 High Maintenance Demands

- Mechanical Components: Stirrers, pumps, and other moving parts can break down. Routine lubrication and checks mitigate failures.

- Corrosion: Metal parts exposed to hydrogen sulfide (a byproduct of anaerobic digestion) may corrode. Consider corrosion-resistant materials.

10.4 Cost Overruns

- Underestimating Construction: It’s crucial to plan for hidden costs like site preparation, excavation, or import of specialized materials.

- Skill Gaps: Unskilled labor or poor design can lead to constant repairs, driving up expenses.

If faced with these hurdles, consult with biogas experts, local agricultural extension officers, or specialized NGOs for technical support. Timely interventions often save substantial time and money.

11. Frequently Asked Questions (FAQ)

Below are common questions people ask about biogas, which often appear in search queries and can help you gain a featured snippet on Google.

Q1: How long does it take to start producing biogas?

It usually takes 2 to 3 weeks for a newly charged digester to begin generating usable gas. The exact timeline depends on factors like temperature, feedstock composition, and digester design.

Q2: Can I use any type of organic waste?

Most organic wastes—including kitchen scraps, animal manure, and agricultural residues—are suitable. However, woody or fibrous materials with high lignin content decompose slowly. Pre-treatment (e.g., grinding or mixing with manure) can improve results.

Q3: What is the typical biogas plant cost for a household system?

A small Gobar Gas Plant for a household can cost anywhere from USD 200 to USD 1,000, depending on design and local material/labor costs. Larger or more advanced systems will naturally be more expensive.

Q4: Is biogas safe to use indoors?

Yes, biogas is generally safe when handled correctly. Always install your stove or appliances in a well-ventilated area, perform regular leak checks, and use certified piping and fixtures.

Q5: Can biogas replace LPG entirely for cooking?

In many cases, yes. With consistent feedstock supply and proper digester maintenance, biogas can fully meet a household’s cooking needs, drastically reducing or eliminating LPG use.

Conclusion & Call to Action

From reducing gobar gas plant cost in rural homes to powering vehicles through Bio CNG Plant technologies, the potential of biogas is vast, diverse, and increasingly indispensable. By converting organic waste into clean, renewable energy, we not only cut down on greenhouse gas emissions but also create a robust economic and social impact—generating local jobs, reducing reliance on imported fuels, and fostering healthier, waste-free communities.

If you’re considering installing a biogas plant, remember to evaluate your daily organic waste availability, budget, and local climatic conditions. Start small—perhaps with a household digester—and scale up as you gain experience and resources. The returns go beyond simple cost savings: you’ll be making a direct, positive contribution to your environment, community, and future generations.

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.