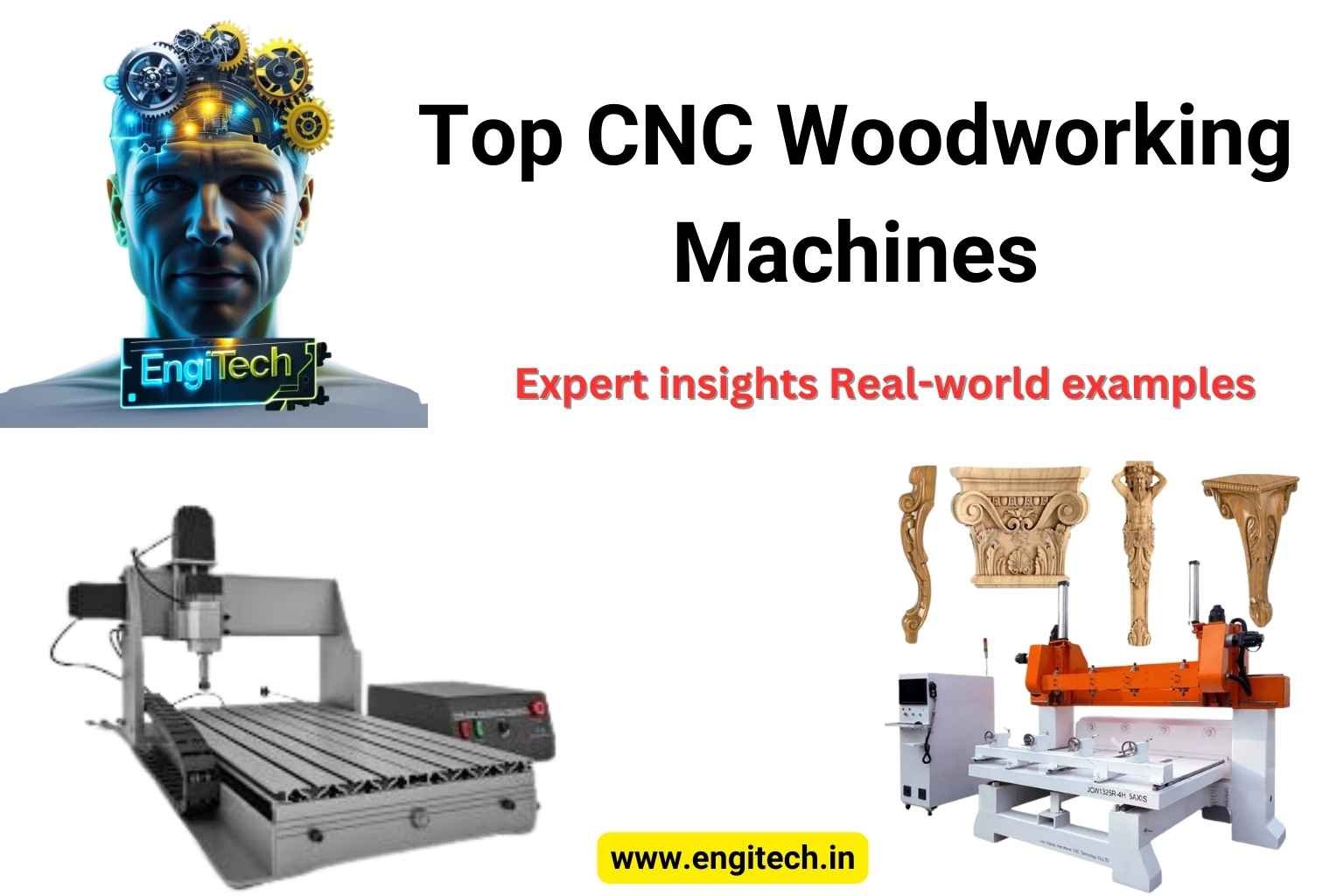

Top CNC Woodworking Machines: Reviews and Prices

Woodworking has evolved from traditional hand tools to advanced Computer Numerical Control (CNC) machines, making it faster, more precise, and highly scalable. Whether you’re a small workshop owner, a hobbyist, or an industrial manufacturer, CNC woodworking machines help you automate complex cuts, engravings, and carvings with minimal human intervention.

But with so many CNC machines on the market, which one should you choose? In this expert-backed guide, we’ll review the best CNC woodworking machines available in 2025, analyze their features, pros and cons, and provide pricing details to help you make an informed decision.

Table of Contents

1. What is a CNC Woodworking Machine?

A CNC (Computer Numerical Control) woodworking machine is an automated cutting tool that operates based on pre-programmed software. These machines can handle cutting, engraving, drilling, milling, and carving with extreme precision.

How CNC Machines Work

- Design & Programming – The user creates a design using CAD/CAM software.

- Machine Setup – Wood is positioned on the worktable, and the cutting tool is selected.

- Automated Cutting – The CNC machine follows the programmed toolpath.

- Final Processing – The finished product may require sanding or finishing.

2. Key Factors to Consider When Buying a CNC Machine

Before investing in a CNC woodworking machine, here are the key factors to consider:

🔹 Size & Work Area

- Desktop CNCs: Ideal for small projects and hobbyists.

- Mid-Sized CNCs: Suitable for small to medium businesses.

- Large Industrial CNCs: Designed for large-scale production.

🔹 Cutting Power & Spindle Speed

- Spindle power (measured in HP or kW) determines how efficiently the machine can cut through different wood types.

- Higher RPM (revolutions per minute) offers smoother, faster cutting.

🔹 Software Compatibility

- Most CNC machines use GRBL, Mach3, or proprietary software.

- Ensure compatibility with your CAD software (AutoCAD, Fusion 360, VCarve, etc.).

🔹 Precision & Accuracy

- Machines with ball screw drives and linear rails offer better accuracy than belt-driven models.

🔹 Price & Budget

- Entry-level CNCs start around $500 – $2,000.

- Mid-range professional models cost $3,000 – $10,000.

- Industrial CNCs range from $15,000 to $100,000+.

3. Top CNC Woodworking Machines: Reviews & Pricing (2025 Edition)

🔸 Best Overall CNC Machine: X-Carve Pro

✔ Best for: Small businesses, professionals, and hobbyists upgrading to a high-performance machine.

| Feature | Details |

| Work Area | 48″ x 48″ |

| Spindle Power | 2HP (1.5kW) |

| Accuracy | ±0.002″ |

| Software | Easel Pro |

| Price | $9,995 |

✅ Pros:

- Large cutting area

- Precision machining

- Beginner-friendly software

❌ Cons:

- Expensive for hobbyists

- Requires dedicated space

🔸 Best Budget CNC Machine: BobsCNC Evolution 4

✔ Best for: Beginners, small-scale woodworkers, and DIY enthusiasts.

| Feature | Details |

| Work Area | 24″ x 24″ |

| Spindle Power | 600W |

| Accuracy | ±0.005″ |

| Software | GRBL-based |

| Price | $1,295 |

✅ Pros:

- Affordable

- Open-source software

- Great for beginners

❌ Cons:

- Requires assembly

- Not suitable for heavy production

🔸 Best Industrial-Grade CNC Machine: ShopBot PRSalpha

✔ Best for: Large workshops and production-scale manufacturers.

| Feature | Details |

| Work Area | 96″ x 48″ |

| Spindle Power | 4HP (3kW) |

| Accuracy | ±0.001″ |

| Software | VCarve Pro |

| Price | $25,000+ |

✅ Pros:

- High precision for professional use

- Heavy-duty build

- Versatile cutting options

❌ Cons:

- Expensive

- Requires professional installation

🔸 Best CNC for Hobbyists & Small Shops: Shapeoko 5 Pro

✔ Best for: Woodworkers who need an affordable yet powerful CNC machine.

| Feature | Details |

| Work Area | 48″ x 48″ |

| Spindle Power | 1.25HP |

| Accuracy | ±0.002″ |

| Software | Carbide Create |

| Price | $3,800 |

✅ Pros:

- User-friendly software

- Excellent accuracy

- Great support community

❌ Cons:

- Requires regular maintenance

4. CNC Software & Accessories: What You Need to Get Started

Apart from the CNC machine, you’ll need:

🔹 Essential Software

- CAD Software (AutoCAD, Fusion 360)

- CAM Software (VCarve, Easel, Carbide Create)

- Control Software (Mach3, GRBL)

🔹 Accessories

- Dust Collection System (Keeps workspace clean)

- Clamping Kits (Secures wood in place)

- High-Quality Router Bits (For precise cuts)

5. Frequently Asked Questions (FAQs)

Q1: What’s the best CNC machine for beginners?

The BobsCNC Evolution 4 is an excellent beginner-friendly machine with an affordable price and easy-to-learn software.

Q2: How much does a professional CNC machine cost?

Professional-grade CNC machines range from $10,000 to $50,000, depending on size and features.

Q3: Can CNC machines work with other materials besides wood?

Yes! Many CNC routers can cut acrylic, aluminum, plastics, and composites with the right spindle and cutting bits.

Q4: How difficult is CNC programming?

Basic CNC programming is easy with beginner-friendly software like Easel and VCarve. More complex operations require knowledge of G-code.

Conclusion & Final Recommendations

If you’re serious about woodworking, investing in a CNC machine can revolutionize your workflow by improving precision, speed, and scalability.

- Best Overall: 🏆 X-Carve Pro

- Best Budget Option: 💰 BobsCNC Evolution 4

- Best Industrial Machine: 🔧 ShopBot PRSalpha

💡 Now it’s your turn! What’s your top choice for a CNC woodworking machine? Let us know in the comments! 🚀

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.