The Ultimate Guide to Sticker Pasting Machines: How to Choose, Operate, and Optimize for Efficiency

Picture this: you’re racing against time in a bustling production environment, juggling multiple tasks, and every second counts toward meeting your daily quota. Yet, your workflow is often interrupted by manual labeling mishaps—crooked stickers, adhesive smudges, or simply running out of time to apply them precisely. If this scenario feels all too familiar, a sticker pasting machine may be the lifeline your operation needs.

In this comprehensive guide, we’ll unveil everything you need to know about these machines—from selecting the right model to maintaining it so your labeling process stays seamless and cost-efficient. By the end, you’ll walk away with actionable insights to solve your current labeling challenges and elevate your production to an entirely new level of professionalism and precision.

Whether you’re a small business owner looking to upgrade from manual sticker applications or a production manager searching for ways to increase throughput, this guide is designed to answer your pressing questions. Stick around to learn how a sticker pasting machine can revolutionize your workflow, reduce human error, and help you stay competitive in a world that demands ever-faster turnaround times.

Table of Contents

1. What Is a Sticker Pasting Machine?

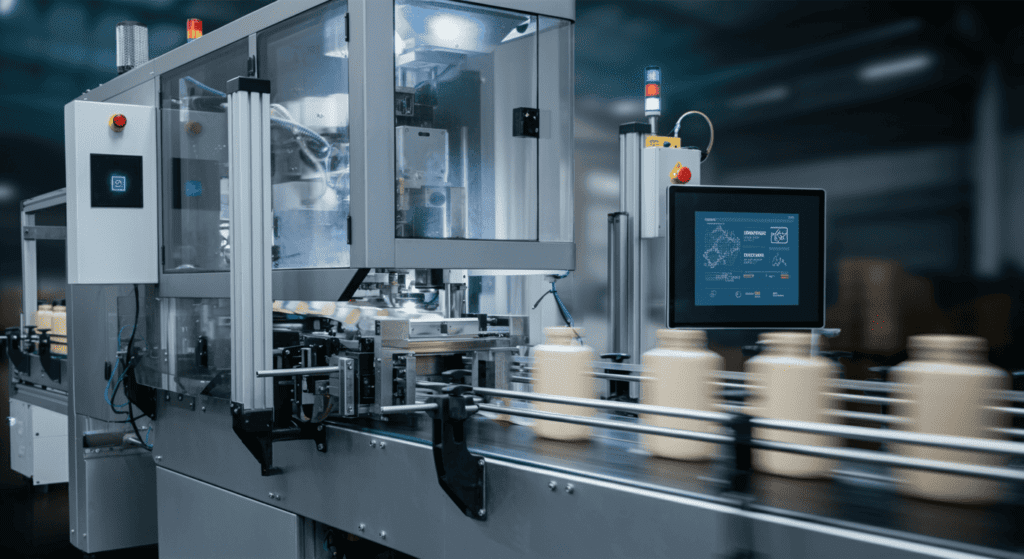

A sticker pasting machine, sometimes referred to as a label application machine or labeling system, is a piece of industrial equipment designed to apply adhesive labels or stickers onto various surfaces with precision. Depending on the model and its level of automation, the machine can handle tasks like feeding, peeling, and pressing stickers onto products—often at speeds and accuracy levels unmatched by manual labor. These machines can accommodate a range of sticker sizes, shapes, and materials, from basic paper labels to more complex, durable decals.

Core Functions

- Automated Feeding: The machine draws stickers from a roll or stack without manual intervention.

- Peeling Mechanism: Labels are peeled from their backing and aligned for optimal placement.

- Application Process: The machine affixes each sticker onto the target surface, minimizing air bubbles and wrinkles.

- Sensor Control: Many models use sensors to detect label positioning, ensuring accurate placement.

Sticker pasting machines are a vital component in industries where labeling is both a legal requirement (like food and pharmaceutical) and a branding necessity (consumer goods and electronics). If you’ve ever seen a line of products at a grocery store with perfectly aligned labels, chances are a sticker pasting machine was behind that flawless presentation.

2. Types of Sticker Pasting Machines

The universe of sticker pasting machines is far from one-size-fits-all. Different operational scales, budgets, and product complexities demand varied solutions. Below are the most common types:

2.1 Manual Sticker Pasting Machines

- Overview: Operated by hand, these machines typically offer limited automation features. They may help with peeling labels off backing paper but rely on manual placement.

- Pros: Low cost, simple setup, minimal space requirements.

- Cons: Limited throughput and prone to human error.

- Best For: Small businesses or short production runs where budget and space are primary concerns.

2.2 Semi-Automatic Sticker Pasting Machines

- Overview: These machines automate some steps (like peeling and alignment) but still require a human operator to feed products and occasionally adjust settings.

- Pros: Faster than manual machines, fewer errors, moderate investment.

- Cons: Still some reliance on manual processes; operator training is essential.

- Best For: Medium-scale operations looking to balance cost with efficiency gains.

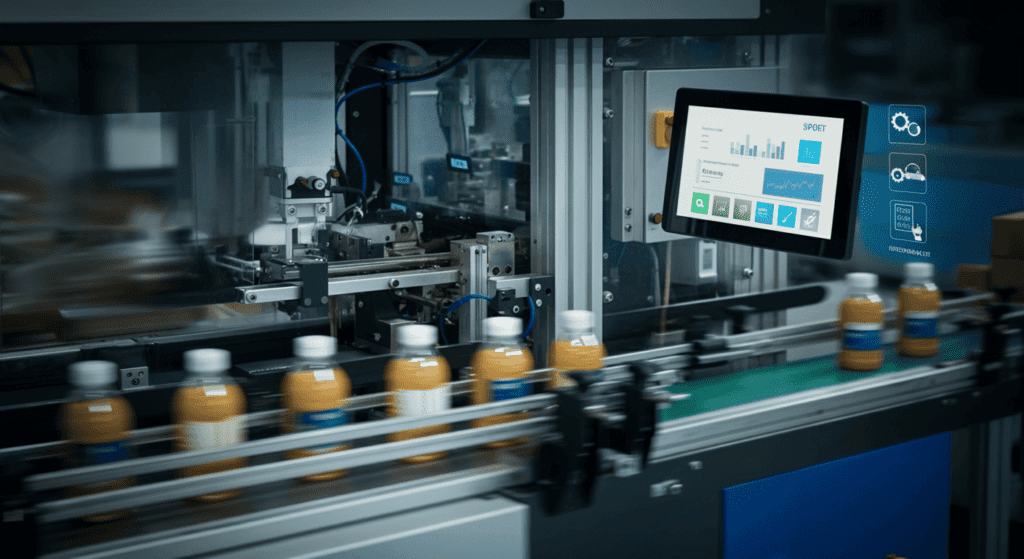

2.3 Fully Automatic Sticker Pasting Machines

- Overview: Offers end-to-end automation—from feeding products to aligning, peeling, and applying stickers. Some advanced models also include inspection systems that reject improperly labeled items.

- Pros: High throughput, minimal human intervention, consistent label placement.

- Cons: Higher initial cost, requires more space and skilled personnel for setup and maintenance.

- Best For: Large-scale production lines where speed, precision, and reduced labor costs are paramount.

2.4 Custom or Specialized Machines

- Overview: Tailored solutions for unique products or specialized industry requirements (e.g., oddly shaped containers or high-temperature environments).

- Pros: Perfectly aligned with your unique production needs, potential for long-term cost savings if standard machines are inefficient for your product.

- Cons: Requires custom engineering, higher upfront costs, longer lead times.

- Best For: Niche industries with specialized requirements, or businesses looking for a bespoke solution that pays off in the long run.

Each category has its own set of trade-offs. Carefully matching your operational needs—whether it’s throughput volume, product shape, or budget constraints—to the right type of sticker pasting machine can be the difference between a chaotic labeling line and a smoothly running operation.

3. Key Components and Features

Understanding the anatomy of a sticker pasting machine can greatly inform your purchase and maintenance decisions. Below are the primary components you’ll encounter:

- Unwinder/Rewinder: Where the label roll is held. The unwinder releases labels, while the rewinder collects the used backing paper.

- Peeling Plate: Separates the label from the backing material, ensuring it’s ready for application.

- Applicator Head: The mechanical arm or roller that presses the sticker onto the product. Some machines use a tamp-blow system for delicate or curved surfaces.

- Conveyor System: In fully automatic models, a conveyor transports products to the labeling station.

- Sensors and Optical Systems: Detects label position and can read product barcodes for alignment or verification.

- Control Panel or HMI (Human-Machine Interface): Allows you to set parameters like speed, label spacing, and alignment.

- Inspection Cameras (Optional): Used in advanced models to verify correct placement or read barcodes/QR codes post-application.

Advanced Features to Look Out For

- Touchscreen Controls: Simplifies the setup process and troubleshooting.

- Memory Storage: Stores multiple labeling “recipes,” enabling quick changeovers for different products.

- Adjustable Speed Settings: Helps you fine-tune the throughput to match production demands.

- Error Detection Alarms: Alerts for label jams, missing labels, or alignment errors.

These components and features work in concert to deliver consistently placed stickers. Familiarizing yourself with each part is crucial for selecting the best model, as well as for ongoing maintenance and troubleshooting.

4. Why Speed and Accuracy Matter

Speed is often seen as the most prominent benefit of a sticker pasting machine, but accuracy holds just as much weight—especially in industries like pharmaceuticals or food and beverage, where misapplied labels can lead to legal repercussions. Even a minor labeling error can cause significant downtime for rework and tarnish your brand reputation.

Real-World Impact

- Production Throughput: Automated systems can apply hundreds to thousands of labels per hour, dwarfing what’s possible with manual labor.

- Reduced Waste: Accurate placements reduce the number of scrapped labels and packaging, which directly impacts your operational costs.

- Compliance: Regulated industries mandate accurate labeling for safety and traceability. Failing to meet these guidelines could result in hefty fines or product recalls.

- Brand Consistency: A crooked or bubbled label can diminish perceived quality, even if the product itself is top-notch.

According to some manufacturing experts, a well-calibrated and fully automatic labeling machine can lower labeling errors by up to 90% compared to manual application. That’s a massive difference in both time saved and brand integrity maintained.

5. How to Choose the Right Sticker Pasting Machine

Selecting the perfect machine for your operation can be overwhelming, particularly given the variety of models and features available. Below are some guidelines to help you navigate this critical decision.

5.1 Define Your Throughput Requirements

- Volume: Estimate how many products you need to label per hour, day, or shift.

- Scalability: Plan for future growth. Will your labeling needs increase significantly in the near future?

5.2 Consider Product Dimensions and Shapes

- Surface Complexity: Does your product have flat surfaces, curves, or ridges?

- Label Size: Some machines excel at applying small labels for vials, while others can handle large, wrap-around labels.

5.3 Budget and ROI

- Initial Investment: Automated machines come with higher upfront costs, but they often pay off in labor and efficiency savings.

- Operating Costs: Factor in maintenance, electricity consumption, and spare parts over the machine’s lifespan.

- ROI Period: Calculate how quickly you can recoup your investment through labor savings, reduced errors, and increased throughput.

5.4 Space Constraints

- Floor Layout: Machines, especially fully automatic models with conveyors, require ample floor space.

- Accessibility: Ensure there’s enough room for operators to perform maintenance and product loading/unloading.

5.5 Vendor Support and Reputation

- Service Contracts: Check if the supplier offers on-site installation, training, and after-sales support.

- References and Reviews: Ask for customer testimonials or case studies. A reputable vendor with a proven track record often indicates better machine reliability.

5.6 Integration and Compatibility

- Existing Production Line: Does the new machine need to integrate with an existing conveyor or packaging system?

- Software Compatibility: Some advanced machines integrate with your ERP system or inventory management platforms for automatic updates of labeling parameters.

Take the time to map these factors to your specific operational needs, and don’t hesitate to consult industry experts or fellow manufacturers who have experience with the models you’re considering. Remember: the best sticker pasting machine is one that not only meets your current needs but also positions you for sustainable growth.

6. Common Use Cases and Industry Applications

One of the beauties of the sticker pasting machine is its versatility. Whether you’re a small artisan business that needs charming labels for handmade candles or a large automotive parts manufacturer that requires durable, heat-resistant stickers, these machines fit a wide range of sectors. Below are a few key industries and use cases:

6.1 Food and Beverage

- Bottle Labeling: Think craft beers, wine bottles, or gourmet sauces requiring wrap-around labels.

- Nutritional Facts: Precise placement of mandatory information is critical for regulatory compliance.

6.2 Pharmaceuticals

- Medicinal Bottles: Small vials or pill bottles need accurately placed labels to avoid dosage mistakes.

- Compliance Labels: Often accompanied by barcodes or QR codes that require perfect scanning alignment.

6.3 Cosmetics and Personal Care

- High-Volume Lines: Beauty products must often be sealed with tamper-evident labels.

- Branding Aesthetics: Skincare containers and makeup packaging rely on eye-catching, accurately placed labels.

6.4 Electronics

- Serial Number Stickers: Electronics require precise barcoded labels for warranty and inventory management.

- Tamper Seals: Protecting product integrity until it reaches the customer.

6.5 Automotive Parts

- Durability: Labels need to withstand heat, oils, and constant handling.

- Traceability: Barcodes or RFID stickers are essential for supply chain tracking.

6.6 Artisanal and Specialty Products

- Handcrafted Goods: Custom stickers that reflect brand personality.

- Short Runs: Semi-automatic machines are a popular choice for small-scale artisans.

Regardless of industry, a sticker pasting machine saves time, maintains brand consistency, and ensures you stay on the right side of regulations. The flexibility in material handling, from paper to synthetic films, means you can adapt the machine for multiple product lines without significant retooling.

7. Maintenance, Troubleshooting, and Best Practices

A top-notch sticker pasting machine is an investment meant to last for years, if not decades. Proper care and operation are essential for maximizing its lifespan and return on investment.

7.1 Routine Maintenance

- Regular Cleaning: Wipe down rollers, sensors, and peeling plates to remove adhesive residue or dust.

- Lubrication: Follow the manufacturer’s guidelines for lubricating bearings and gears.

- Alignment Checks: Calibration of sensors and applicator heads ensures consistent label placement.

7.2 Troubleshooting Common Issues

- Label Jams: Often caused by misaligned rolls or debris in the peeling mechanism. Clean and realign.

- Skewed Labels: Can stem from incorrect sensor settings or conveyor misalignment. Adjust sensor sensitivity or realign the conveyor.

- Machine Downtime: Electrical faults or software glitches. Always keep a log of error messages to expedite repairs.

7.3 Best Practices

- Operator Training: A well-trained operator can quickly spot and fix minor issues before they escalate.

- Scheduled Servicing: Consider an annual or biannual service contract with the manufacturer or a certified technician.

- Use Quality Labels: Low-grade sticker materials often cause more jams and alignment problems. Investing in reliable label stock reduces downtime.

- Spare Parts Inventory: Keep critical spares (like belts, sensors, and rollers) on hand to reduce repair time.

By embedding these maintenance rituals into your standard operating procedures, you’ll enjoy minimal downtime, reduced operational costs, and consistent output quality.

8. Cost Considerations and ROI

While the upfront cost of a sticker pasting machine can appear daunting, it’s crucial to view it in the broader context of long-term savings and operational improvements. Over time, most businesses find that automating their labeling process pays for itself in multiple ways.

8.1 Upfront vs. Long-Term Costs

- Purchase Price: Varies significantly based on automation level, additional features, and brand reputation.

- Installation and Training: Could be included in the machine’s price or billed separately.

- Maintenance and Parts: Expect periodic costs for servicing, especially with heavily used machines.

8.2 Labor and Error Reduction

- Reduced Staffing Needs: With an automatic machine, fewer operators are required to maintain throughput.

- Minimized Label Waste: Accurate placements cut down on label and packaging reworks.

- Quality Control: Fewer errors mean higher brand consistency and fewer returns from unhappy customers.

8.3 Productivity Gains

- Higher Throughput: Automated lines often label 2-5 times faster than manual methods.

- Improved Employee Morale: Repetitive manual labeling can be tedious; automation frees employees for more engaging tasks.

8.4 ROI Analysis

A typical ROI analysis might consider:

- Current labor cost for manual labeling.

- Number of labeling errors and associated cost of rework or returns.

- Projected increase in production volume after installation.

- Timeline to break even based on savings and added revenue from increased efficiency.

Many businesses find they can recoup their investment in a fully automatic sticker pasting machine within 12 to 24 months, making it a financially prudent move for those committed to scaling their operations.

9. Future Trends in Sticker Pasting Technology

The world of labeling is evolving rapidly, influenced by advancements in automation, sustainability, and digital integration. Staying on top of these trends can help you future-proof your investment.

9.1 Smart Labeling Systems

As the Internet of Things (IoT) expands, sticker pasting machines increasingly offer connectivity features—allowing real-time performance monitoring, predictive maintenance alerts, and seamless integration with inventory management platforms.

9.2 Eco-Friendly Materials

Sustainability is no longer optional for many industries. Expect more machines capable of handling eco-friendly label materials (biodegradable or compostable adhesives and backing papers) without compromising speed or quality.

9.3 Modular Designs

Manufacturers are embracing modular components that make it easier to upgrade or reconfigure machines. You might start with a semi-automatic base and then add a conveyor or inspection camera later.

9.4 AI and Machine Vision

Artificial intelligence is making inroads into label inspection and quality control. Machine vision algorithms can detect micro-misalignments or print defects on labels, helping catch errors before they reach consumers.

9.5 Customized User Interfaces

User-friendly touchscreens with drag-and-drop functionality, multi-language support, and built-in tutorial videos are becoming standard. This reduces the learning curve and speeds up changeovers.

Keeping an eye on these trends ensures that your labeling operations remain competitive, efficient, and aligned with future market demands.

FAQs About Sticker Pasting Machines

Below are some frequently asked questions that often arise when businesses explore automating their labeling process. Adding these in a structured FAQ format can help optimize your content for Google’s Featured Snippets.

Q1: Are sticker pasting machines compatible with different label materials?

A1: Yes, most modern sticker pasting machines can handle a variety of materials, including paper, polyester, vinyl, and biodegradable substrates. Always check with the manufacturer for any specific material constraints.

Q2: Can I integrate a sticker pasting machine with my existing production line?

A2: Absolutely. Many fully automatic machines are designed for seamless integration with conveyor systems and can be programmed to match your existing line speed. You may need additional sensors or a synchronization kit, but most reputable suppliers provide detailed guidance for such integrations.

Q3: Do I need special software or training to operate the machine?

A3: Many machines include user-friendly software and touchscreens that simplify operation. Basic operator training is often sufficient, but for advanced features like label design or multiple product line setups, you might need additional training from the manufacturer.

Q4: How often should I perform maintenance?

A4: Routine maintenance, like cleaning and sensor checks, should be performed daily or weekly, depending on usage. More thorough servicing, such as lubrication and component inspections, may be scheduled monthly or quarterly.

Q5: What if I want to change my label design frequently?

A5: Machines with programmable memory or quick-change features can store multiple label “recipes.” Switching from one product label to another can be done in minutes, making frequent design updates less disruptive.

Conclusion

In today’s hyper-competitive manufacturing and retail landscape, efficiency isn’t just a buzzword—it’s the key to survival. A sticker pasting machine offers a formidable advantage by automating a task that is both repetitive and error-prone when done by hand. From improving throughput to ensuring brand consistency and regulatory compliance, these machines embody a reliable investment that can transform your production line.

As you consider your options, remember to assess factors like throughput, space constraints, and future growth plans. Revisit the best practices and maintenance tips outlined here to keep your machine running at peak performance, and don’t overlook the power of advanced features like AI-driven inspection for an additional layer of quality control.

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.