The Ultimate Guide to Choosing the Perfect Water Bottle Label Printing Machine

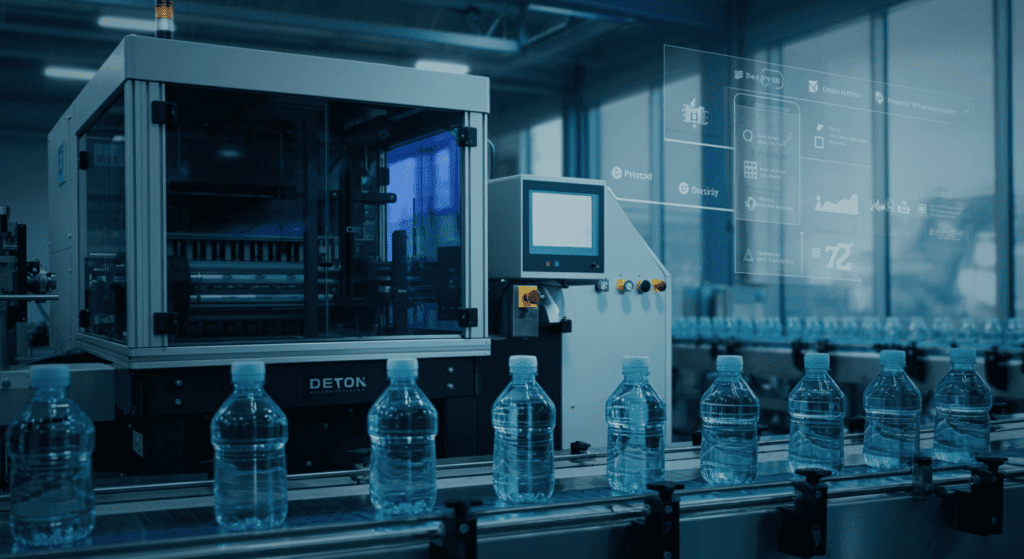

Imagine standing in a busy grocery aisle, comparing bottled water brands. You pick up one bottle after another, noticing crisp labels with eye-catching designs—some minimalistic, some vibrant, all reflecting distinct brand personalities. In today’s market, a water bottle label isn’t just a sticker; it’s a critical communication tool. It shows off brand identity, lists nutritional facts, and conveys a product’s quality. The quest for the ideal water bottle label printing machine has never been more crucial for businesses looking to differentiate themselves in a saturated marketplace.

In this comprehensive guide, you’ll learn how to select, operate, and maintain a water bottle label printing machine that aligns with your production goals and brand vision. We’ll cover everything from basic machine types to advanced features and real-world success stories. By the end, you’ll have the know-how to optimize your labeling operations, stay compliant with industry standards, and confidently outshine your competitors.

Table of Contents

1. Why Quality Labeling Matters

The label on a water bottle isn’t just about aesthetics; it’s a gateway to multiple facets of your business and brand.

- Brand Recognition

An attractive label catches the consumer’s eye and sets your product apart. High-resolution print clarity, vibrant colors, and durability all bolster brand confidence. - Consumer Confidence

Labels often list important information—like ingredients, certifications, or water source details. When these are clear and easy to read, customers trust your brand more. - Regulatory Compliance

Many local and international regulations require specific information on labels (e.g., nutritional facts, barcodes, batch numbers). A reliable water bottle label printing machine ensures that your labels meet these guidelines consistently. - Product Differentiation

With hundreds of bottled water brands on the shelf, compelling label design helps capture attention. Even subtle differences in the finish or font can give you a competitive edge.

A subpar labeling process can undermine your marketing efforts. Blurry prints, misaligned text, or peeling edges instantly create a poor impression. Investing in a top-notch label printing solution pays dividends in brand loyalty and long-term growth.

2. Common Types of Water Bottle Label Printing Machines

Before diving into advanced features, it’s crucial to understand the fundamental categories of label printing machines. Each type serves a unique purpose and is ideal for particular production scales and budgets.

2.1 Flexographic Label Printing Machines

Flexographic printing (often shortened to “flexo”) involves using flexible relief plates wrapped around cylinders. The process applies quick-drying ink onto a variety of materials, such as paper, film, or foil. Flexo machines are known for:

- High-speed production

- Wide material compatibility

- Suitable for large-volume runs

For water bottle labels, flexo printing offers excellent durability and color consistency, making it a popular choice for medium to large manufacturers.

2.2 Digital Label Printing Machines

Digital printers use advanced inkjet or laser technology to print directly onto label stock. They’re especially valued for:

- Short runs and quick turnarounds

- Minimal setup time (no plates required)

- High-resolution color reproduction

If you’re a startup or a niche brand requiring frequent label changes, digital machines are perfect for test batches or limited-edition product lines. While the per-unit cost can be higher than flexo, the flexibility and speed to market are unmatched.

2.3 Offset Label Printing Machines

Offset printing has long been an industry standard for high-volume jobs. This method transfers ink from a metal plate to a rubber blanket, then onto the printing surface. Key benefits include:

- Cost-effectiveness at very high volumes

- Sharp image quality and color consistency

- Complex design reproduction

Offset presses are popular in large-scale water bottling operations that rarely change label designs and need consistent output at scale.

2.4 Hybrid Label Printing Machines

Hybrid solutions combine digital and conventional printing methods (like flexo or offset) into one system. This dual capability:

- Enables personalization and variable data printing

- Maintains large-volume efficiency

- Delivers premium color effects and textures

Hybrid machines can handle short-run customization without sacrificing long-run efficiency. They’re a strategic investment for brands juggling multiple SKUs or frequent seasonal campaigns.

3. Key Components and Features to Consider

No matter which type of machine you choose, there are essential components and features to prioritize.

3.1 Print Resolution and Color Fidelity

- High DPI (dots per inch) ensures crisp text and vivid images.

- Look for machines that support a wide color gamut, including spot colors.

- If you’re printing premium water bottle labels, consider machines with multiple ink channels for nuanced gradients and brand-accurate Pantone shades.

3.2 Print Speed

- Production rate (labels per minute or linear feet per minute) directly impacts your operational throughput.

- Evaluate your current and projected demands to ensure the machine meets your required speed.

- Don’t forget to factor in variables like drying time or curing time for certain inks.

3.3 Automation and Integration

- Automatic label applicators can seamlessly integrate with your water bottle label printing machine to reduce manual intervention.

- Many modern systems offer IoT features for real-time performance tracking and troubleshooting.

- If you scale production across multiple lines or facilities, advanced software integration (e.g., ERP or MES systems) can streamline your entire workflow.

3.4 Ink Compatibility

- Water-based inks are eco-friendly and suitable for certain surfaces.

- UV-curable inks dry faster and can handle a variety of substrates.

- Solvent-based inks typically offer excellent durability against moisture and abrasion, critical for water bottle labels that endure refrigeration and handling.

3.5 Substrate Handling

- Make sure your machine can handle different label stocks (paper, plastic film, metallized foil) and thicknesses.

- Features like tension control and automated web guides help maintain consistent print quality and reduce material waste.

3.6 Quality Control Systems

- Advanced machines incorporate in-line inspection cameras to detect print defects in real time.

- Automated error-correction features prevent wasted material.

- Barcode verification ensures accurate tracking and regulatory compliance.

4. How the Label Printing Process Works

Understanding the fundamental workflow can help you optimize every step. While the details vary by machine type, the core process remains relatively similar.

- Design & Prepress

You create or finalize your label design with layout software. For flexographic or offset machines, this step includes plate-making. For digital, it’s all about file preparation and color management. - Material Loading

The chosen substrate—paper, film, or specialized synthetic—gets loaded onto the machine. Operators ensure tension settings, roller alignments, and web guides are calibrated for smooth feeding. - Ink Transfer & Printing

- Flexo/Offset: Ink is transferred from plates or blankets onto the substrate.

- Digital: Ink droplets are precisely laid down onto the substrate via inkjet heads or laser processes.

- UV-Curable: UV lamps rapidly cure the ink before it can smudge.

- Drying/Curing

Once the ink is applied, it needs to dry. UV-curable inks dry almost instantly under UV lamps. Water-based or solvent-based inks may require heated dryers or extra time. - Inspection & Finishing

- Inspection Systems: Cameras or sensors identify defects.

- Finishing: This might include lamination for protection, die-cutting into individual labels, or slitting large rolls into narrower widths.

- Label Application

If your setup includes an applicator, the machine can automatically apply labels to bottles. Otherwise, the finished labels are shipped or transferred to a separate line for application.

5. Choosing the Right Label Materials

Picking the correct substrate and adhesive can make or break your label’s performance in the real world.

- Paper Labels

- Typically cost-effective and easy to print.

- Not as durable when exposed to moisture, unless treated with a protective coating.

- Film Labels (BOPP, PET, PVC)

- Better moisture resistance, crucial for water bottles.

- Glossy or clear finishes that allow unique design effects.

- Typically require specialized inks or adhesives.

- Eco-Friendly Materials

- Biodegradable films or recyclable paper.

- Ideal for brands with a strong sustainability message.

- Ensure your water bottle label printing machine supports these specialized materials.

- Adhesive Considerations

- Water-based vs. solvent-based adhesives.

- Peel-and-reseal options if your product demands reusability of the bottle.

- Always conduct environment-specific tests (e.g., cold-storage environments, humidity, high-altitude transport).

6. Compliance and Regulatory Insights

Water bottles are considered a consumable product in many regions, which means strict labeling rules.

- FDA & USDA Guidelines (US Market)

- Nutrition facts and ingredient lists must be accurate.

- All claims (like “spring water” or “purified water”) need to align with regulatory definitions.

- Barcodes may need to meet specific readability standards.

- EU Labeling Regulations

- Mandatory language requirements if selling in multiple countries.

- Clear allergen labeling if applicable (in some bottled water variants with additives).

- Use legible fonts and standardized icons for recycling directives.

- International Symbols and Certifications

- Kosher, Halal, or organic logos, if applicable.

- Industry certifications like NSF or ISO 9001.

- Traceability Codes: Batch codes or date codes must be easy to read and permanent enough to withstand distribution.

Working with a printing solution that ensures consistent, high-quality output helps you avoid costly recalls or legal complications. Always verify you have the right water bottle label printing machine settings, especially when printing mandatory safety or nutritional data.

7. Optimizing Production Efficiency

Once your machine is in place, maximizing its output is the next priority. Below are strategies to refine production and maintain high throughput without sacrificing quality.

- Lean Workflow Layout

- Position your printing equipment, material storage, and application lines to minimize travel time.

- Use color-coded lanes or signage to create a seamless flow of materials and finished labels.

- Changeover Efficiency

- Quick-change ink systems or modular print heads can drastically reduce downtime when switching label designs.

- Implement standardized job setups and store machine settings for repetitive runs.

- Preventive Maintenance

- Create a routine maintenance schedule for cleaning print heads, replacing rollers, and calibrating sensors.

- Inspect mechanical parts like bearings and belts to preempt costly breakdowns.

- Employee Training

- Conduct hands-on training so operators understand the machine’s features and troubleshooting steps.

- Encourage continuous improvement; small adjustments in technique can lead to significant gains in speed and consistency.

- Data-Driven Decision Making

- Utilize built-in sensors and performance dashboards for real-time monitoring.

- Analyze throughput rates, reject rates, and downtime incidents to identify bottlenecks.

8. Maintenance Best Practices

A well-maintained water bottle label printing machine can run efficiently for years, sometimes decades.

- Daily Visual Inspections

- Check for ink leaks, loose screws, or worn cables.

- Verify the substrate alignment and tension settings.

- Scheduled Cleaning

- Remove ink residue from rollers, print heads, and plates to ensure crisp print quality.

- Use recommended cleaning solutions to avoid damaging sensitive components like lenses or sensors.

- Lubrication & Replacements

- Keep mechanical parts (bearings, gears, shafts) lubricated as recommended by the machine’s manufacturer.

- Stock key spare parts, including belts, sensors, or circuit boards, to minimize downtime in emergencies.

- Software & Firmware Updates

- Stay on top of the latest patches or version upgrades that improve machine stability or add new features.

- Some modern systems offer remote diagnostics, allowing tech support to troubleshoot issues quickly.

- Documentation & Record-Keeping

- Maintain detailed service logs.

- Track machine performance trends to schedule predictive maintenance rather than reacting to breakdowns.

9. Cost Considerations and ROI

Investment in a water bottle label printing machine can range from a few thousand dollars for entry-level digital setups to millions for industrial-scale hybrid presses. Here’s how to approach budget planning:

- Initial Purchase vs. Total Cost of Ownership (TCO)

- Factor in ink and substrate costs, maintenance, operator training, and potential upgrades.

- A lower upfront cost might mean higher operational expenses over time.

- Scaling Up Production

- If you anticipate rapid growth, investing in a machine that can handle future demand might be more economical than multiple equipment upgrades.

- Consider modular or upgradable systems for flexibility.

- Calculating ROI

- Compare per-label printing costs against outsourcing.

- Assess intangible benefits like improved brand consistency, faster turnaround, and fewer misprints.

- Efficient labeling often leads to lower packaging errors, which can save large sums over the long run.

- Lease vs. Purchase

- Leasing can free up capital but may come with long-term interest or monthly fees.

- Purchasing outright gives you full control and often leads to better ROI if you use the machine consistently.

10. Real-World Examples & Case Studies

Seeing these machines in action can clarify how they boost efficiency and brand presence.

10.1 Sparkling Springs: Upgrading to Digital Printing

Sparkling Springs, a boutique water brand, struggled with frequent label design changes and limited storage space for printed label rolls. By adopting a digital label printing machine, they:

- Reduced label turnaround from two weeks to two days

- Eliminated bulk label storage

- Experimented with seasonal designs, boosting sales by 20% during summer months

10.2 AquaPure: Shifting from Manual to Automated Label Application

AquaPure relied on manual labeling in its early stages. As demand soared, inconsistencies and labor costs became unsustainable. They purchased a flexographic printing machine with an integrated applicator:

- Achieved a consistent, professional label look

- Increased daily output by 40%

- Reduced labor costs by 30%, reallocating staff to quality checks and logistics

10.3 EcoVital: Embracing Sustainable Materials

EcoVital, an environmentally conscious brand, switched to biodegradable film labels. They upgraded their digital printer to handle the specialized substrate:

- Reduced plastic usage by 15%, winning eco-awards

- Strengthened brand image among eco-focused consumers

- Maintained high-quality print resolution, preserving brand colors and artwork

These examples underscore how the right machine selection and features can create tangible value across diverse business models.

FAQs About Water Bottle Label Printing Machines

Below are some frequently asked questions that address practical concerns and potential issues.

FAQ 1: How do I choose the best water bottle label printing machine for my startup?

Start by assessing your average label run size, budget, and design complexity. If you need frequent design changes and short runs, a digital machine may be ideal. If large volume and cost-per-label are your focus, flexo or offset could be more economical.

FAQ 2: Which label material is best for water bottles stored in cold environments?

Film-based labels like BOPP or PET are well-suited for moisture-rich and cold conditions. They resist peeling and maintain vibrant print quality even when stored in refrigerators or ice chests.

FAQ 3: How frequently should I calibrate my label printing machine?

Monthly calibration is a good rule of thumb for most machines. However, high-usage lines or those working with delicate substrates might require weekly checks to maintain top-tier print quality.

FAQ 4: Can I print variable data (like batch numbers) on water bottle labels?

Absolutely. Many modern machines support variable data printing, especially digital and hybrid systems. This feature allows you to include individualized barcodes, batch numbers, or promotional codes on each label without stopping production.

FAQ 5: Are water-based inks durable enough for bottled water labels?

Yes, many water-based inks—especially those designed for packaging—provide ample moisture resistance. For extra protection, consider a finishing step like lamination or use UV-curable inks if your products face harsh environmental conditions.

Conclusion

Selecting the perfect water bottle label printing machine can feel overwhelming, but focusing on your operational needs, brand requirements, and budget narrows down the best-fit solution. High-quality labeling isn’t just a marketing tool; it’s a pathway to consumer trust, regulatory compliance, and long-term profitability.

From understanding different printing technologies (flexo, digital, offset, hybrid) to honing in on material selection and workflow optimization, you now have a 360-degree view of how to approach the labeling process. By integrating the right machine with strong maintenance habits, thorough employee training, and smart cost analysis, you’ll set your production line up for sustained success.

External Authority Links (Suggested)

Stay Connected with EngiTech

EngiTech is your trusted source for in-depth knowledge on industrial mechanical engineering machines and technologies. Stay ahead with the latest innovations, expert insights, and practical guides designed to help you make informed decisions for your business and engineering needs. Join our growing community of professionals and industry leaders to stay updated and competitive in the ever-evolving world of industrial technology.