Optical Comparators: Ultimate Guide to Precision Measurement

Optical comparators are indispensable tools in the field of precision measurement and quality control. They offer a non-contact method of inspecting the geometry of manufactured parts, providing accurate and reliable data. This detailed guide will explore the workings of optical comparators, their applications, advantages, and how they contribute to modern manufacturing processes.

Table of Contents

What Are Optical Comparators?

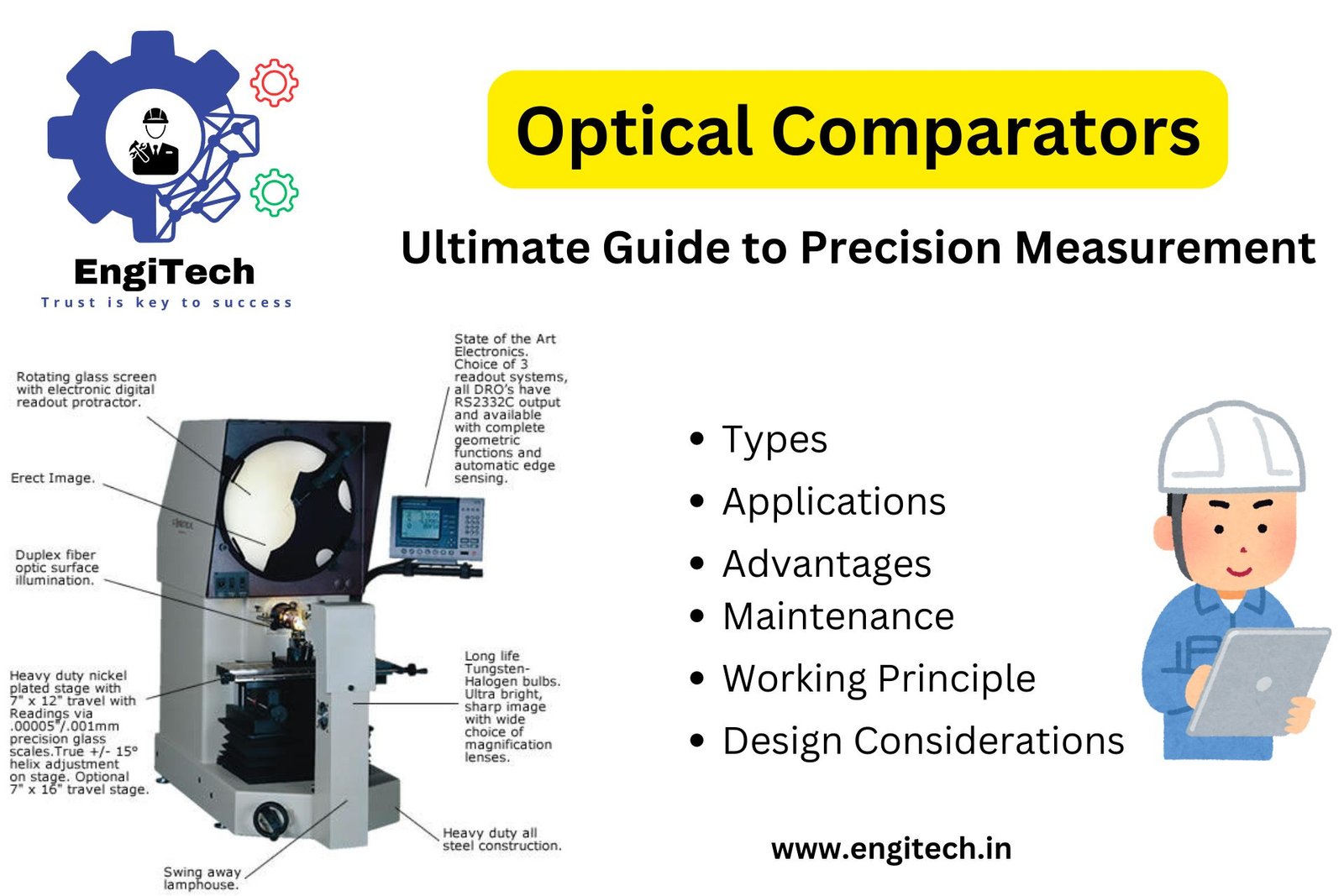

Optical comparators, also known as profile projectors, are instruments used to measure and compare the dimensions of small parts. They project a magnified image of the part onto a screen, allowing the operator to compare it against a standard template or digital model. This non-destructive testing method ensures that parts meet specific design requirements without physically altering them.

Optical comparators are essential in industries where precision is paramount, such as aerospace, automotive, and medical device manufacturing. They play a critical role in maintaining the quality and consistency of products, ensuring that each component meets the required specifications.

How Do Optical Comparators Work?

Optical comparators function by projecting light onto a part, which is then magnified and displayed on a screen. Here’s a step-by-step breakdown of how they operate:

- Illumination: The part is placed on the stage of the optical comparator, and light is projected onto it. The light can be transmitted (through the part) or reflected (off the surface), depending on the nature of the component.

- Magnification: The optical system of the comparator magnifies the image of the part, typically using lenses that provide various levels of magnification, such as 10x, 20x, or 50x.

- Projection: The magnified image is projected onto a screen where the operator can view it. The screen often has a grid or overlay that allows for precise measurement and comparison.

- Measurement: The operator can measure the dimensions of the part by comparing it to a pre-determined standard or using digital tools integrated into modern optical comparators. Measurements can include angles, radii, lengths, and other geometric properties.

Key Components of Optical Comparators

Understanding the key components of optical comparators helps in appreciating their functionality:

- Light Source: Provides the necessary illumination, which can be adjustable to suit different materials and inspection requirements.

- Lenses: These are crucial for magnifying the image and can be swapped out to achieve different magnification levels.

- Screen: Displays the magnified image, often with a grid or reticle to assist in measurement.

- Stage: A movable platform where the part is placed. The stage can be adjusted to position the part precisely.

- Digital Readout: In modern optical comparators, a digital display shows the measurements, enhancing accuracy and ease of use.

Types of Optical Comparators

There are several types of optical comparators, each designed for specific applications:

- Benchtop Optical Comparators: These are compact and suitable for small parts or limited workspace environments. They offer high precision and are commonly used in laboratories and small production facilities.

- Floor-Standing Optical Comparators: Larger and more robust, these comparators are ideal for inspecting larger parts or handling high volumes of inspections in industrial settings.

- Horizontal Optical Comparators: These project the image horizontally and are used for parts that are longer in one dimension, such as shafts or rods.

- Vertical Optical Comparators: Project the image vertically, making them suitable for flat or shorter components. They are often used in the inspection of small, intricate parts.

Applications of Optical Comparators

Optical comparators are versatile instruments with a wide range of applications across various industries. Some of the common uses include:

- Quality Control: Ensuring that parts meet precise design specifications before they are assembled or shipped to customers.

- Reverse Engineering: Recreating the design of a part by measuring its dimensions and features using an optical comparator.

- Tool and Die Making: Inspecting the geometry of tools and dies to ensure they meet the required tolerances.

- Medical Device Manufacturing: Verifying the dimensions of medical implants and instruments, where precision is critical.

- Aerospace Industry: Checking the dimensions of aerospace components to ensure they meet stringent safety and performance standards.

Advantages of Using Optical Comparators

Optical comparators offer several advantages that make them a preferred choice in precision measurement:

- Non-Contact Measurement: Optical comparators measure parts without physically touching them, which eliminates the risk of damaging delicate components.

- High Precision: These instruments provide highly accurate measurements, even for small and intricate parts.

- Ease of Use: Operators can quickly learn to use optical comparators, making them accessible tools in various settings.

- Versatility: Optical comparators can measure a wide range of parts and materials, making them useful in many industries.

- Cost-Effective: Compared to more advanced measurement tools, optical comparators offer a cost-effective solution for many quality control tasks.

- Visualization: The magnified image allows for easy inspection of part features, helping to identify defects or deviations from the standard.

Disadvantages and Limitations

While optical comparators are highly useful, they do have some limitations:

- Manual Operation: Most optical comparators require manual operation, which can introduce human error if not performed carefully.

- Limited Automation: Unlike some modern measurement tools, optical comparators typically do not offer full automation, which can slow down the inspection process.

- Size Constraints: The size of the part that can be inspected is limited by the stage and screen size, making them unsuitable for very large components.

- Dependence on Operator Skill: The accuracy of the measurements can depend heavily on the skill and experience of the operator.

Optical Comparators vs. Other Measurement Tools

In the field of precision measurement, optical comparators are often compared to other tools like coordinate measuring machines (CMMs), vision systems, and laser scanners. Each tool has its advantages, and the choice depends on the specific application:

- CMMs: Coordinate measuring machines are highly accurate and can measure complex geometries in three dimensions. However, they are more expensive and slower than optical comparators.

- Vision Systems: These systems use cameras and software to measure parts. They offer high automation and are suitable for complex inspections but may not provide the same level of visualization as optical comparators.

- Laser Scanners: Laser scanners provide fast and accurate measurements and can create detailed 3D models of parts. However, they are more costly and may require more complex setups.

Expert Insights: Best Practices for Using Optical Comparators

Our expert engineers recommend the following best practices when using optical comparators:

- Calibration: Regularly calibrate the optical comparator to ensure accurate measurements. Calibration should be performed according to the manufacturer’s specifications.

- Lighting: Adjust the lighting based on the material and surface finish of the part. Proper lighting is crucial for obtaining a clear and accurate image.

- Magnification Selection: Choose the appropriate magnification level based on the part’s size and the required measurement accuracy. Higher magnification can reveal finer details but may also introduce more challenges in aligning the part.

- Positioning: Ensure the part is correctly positioned on the stage to avoid parallax errors. Use the stage controls to fine-tune the part’s alignment.

- Regular Maintenance: Keep the lenses and screen clean, and perform regular maintenance on the optical comparator to ensure it operates at peak performance.

Future Trends in Optical Comparators

The field of optical comparators is evolving with advancements in technology. Some of the emerging trends include:

- Digital Integration: Modern optical comparators are increasingly integrated with digital measurement systems, allowing for automated data capture and analysis.

- Enhanced Software: Advanced software tools are being developed to assist operators in making more accurate measurements and reducing human error.

- Portable Optical Comparators: There is a growing demand for portable optical comparators that can be used in the field or at different locations within a manufacturing facility.

- Integration with Industry 4.0: Optical comparators are being integrated into smart manufacturing systems, where they can communicate with other machines and contribute to real-time quality control.

Frequently Asked Questions (FAQs) About Optical Comparators

- What is an optical comparator?

- An optical comparator is a precision measurement tool used to inspect and measure the geometry of small parts by projecting a magnified image onto a screen.

- How does an optical comparator work?

- Optical comparators work by projecting light onto a part, magnifying the image through lenses, and displaying it on a screen for measurement and comparison against a standard.

- What industries use optical comparators?

- Optical comparators are widely used in industries such as aerospace, automotive, medical devices, and tool and die making, where precision measurement is crucial.

- What are the advantages of using an optical comparator?

- Advantages include non-contact measurement, high precision, ease of use, versatility, cost-effectiveness, and excellent visualization of part features.

- Can optical comparators measure complex geometries?

- While optical comparators are excellent for measuring simple geometries, they may have limitations when measuring highly complex or three-dimensional shapes compared to tools like CMMs.

- How do I calibrate an optical comparator?

- Calibration should be done regularly using certified calibration standards, following the manufacturer’s instructions to ensure accurate measurements.

- What types of parts can be measured with an optical comparator?

- Optical comparators can measure a wide range of parts, including flat components, shafts, gears, threads, and more, provided they fit within the comparator’s stage.

- What is the difference between horizontal and vertical optical comparators?

- Horizontal comparators project the image horizontally and are used for longer parts, while vertical comparators project vertically and are suited for flat or shorter components.

- Are optical comparators still relevant in modern manufacturing?

- Yes, optical comparators remain relevant due to their precision, ease of use, and cost-effectiveness, especially when integrated with modern digital tools and software.

- What should I consider when choosing an optical comparator?

- Consider factors like the part size, required precision, magnification options, stage size, digital integration, and the specific needs of your inspection tasks.

- How can I ensure accurate measurements with an optical comparator?

- To ensure accuracy, regularly calibrate the comparator, use appropriate lighting and magnification, position the part correctly, and follow best practices in operation.

- What is the difference between an optical comparator and a vision system?

- Optical comparators use magnified light projections, while vision systems use cameras and software for measurement. Vision systems offer more automation but may lack the visualization quality of optical comparators.

- How can optical comparators be integrated with digital systems?

- Many modern optical comparators come with digital readouts and software integration, allowing for automated data capture, analysis, and reporting.

- What is the typical accuracy of an optical comparator?

- The accuracy of an optical comparator can vary depending on the model and magnification level but typically ranges from 0.001 to 0.01 inches.

- Can optical comparators be used for reverse engineering?

- Yes, optical comparators are often used in reverse engineering to recreate the design of parts by measuring and analyzing their dimensions.

These FAQs cover the most common queries related to optical comparators, helping users understand their functionality, applications, and benefits.

Conclusion

Optical comparators remain a vital tool in the field of precision measurement and quality control. Their ability to provide accurate, non-contact measurements makes them indispensable in industries where precision is key. By understanding their operation, applications, and best practices, you can maximize their potential and ensure that your manufacturing processes meet the highest standards of quality.

For students, knowledge seekers, and working professionals, mastering the use of optical comparators can open doors to various opportunities in fields like aerospace, automotive, and medical device manufacturing. As technology continues to evolve, staying updated with the latest advancements in optical comparators will be essential for anyone involved in precision measurement and quality control.

This blog has covered the essential aspects of optical comparators, offering insights from our expert engineers and addressing common queries. By following the guidelines and best practices discussed here, you can ensure that your use of optical comparators is both effective and efficient, contributing to better quality control and improved manufacturing outcomes.

From EngiTech Team

EngiTech is dedicated to empowering professionals, students, and knowledge seekers in the world of industrial engineering. Our comprehensive resources and expert insights provide the knowledge you need to stay ahead in today’s fast-paced industry. Whether you’re looking to enhance your understanding of precision tools like optical comparators or seeking in-depth analysis of the latest engineering technologies, EngiTech is your trusted source. Explore our expert-driven content and discover how we can help you achieve excellence in your field.