Comprehensive Guide to Jig Boring Machines

Jig boring machines are essential tools in precision machining, used to create accurately sized and positioned holes. This comprehensive guide will delve into the various types of jig boring machines, their designs, working principles, applications, advantages, and maintenance practices.

Table of Contents

Introduction to Jig Boring Machines

Jig boring machines are precision machines designed to produce highly accurate holes and to ensure the precise alignment of components. They are used in industries where exact measurements and tight tolerances are crucial, such as aerospace, automotive, and manufacturing. The primary advantage of jig boring machines is their ability to produce consistent and repeatable results, making them indispensable in precision machining.

Working Principle of Jig Boring Machines

Jig boring machines are precision tools designed to create accurately positioned holes and to ensure the precise alignment of components. The working principle of jig boring machines involves several key components and steps to achieve the high level of accuracy required in various industrial applications. Here’s a detailed explanation of how jig boring machines operate:

1. Machine Structure

Jig boring machines are built with a robust and stable structure to minimize vibrations and ensure precision. The main structural components include the base, column, table, and spindle.

- Base: Provides a stable foundation for the machine, ensuring minimal movement during operation.

- Column: Supports the spindle and other moving parts, ensuring rigidity.

- Table: Holds and positions the workpiece accurately.

- Spindle: Houses the cutting tool and performs the drilling operation.

2. Spindle Movement

The spindle is the key component of a jig boring machine. It moves vertically (in the case of vertical jig boring machines) or horizontally (in the case of horizontal jig boring machines) to create precise holes. The spindle movement is controlled to achieve the desired depth and positioning of the hole.

- Vertical Movement: The spindle moves up and down to drill holes in the workpiece.

- Horizontal Movement: In some machines, the spindle can also move horizontally to create holes at different angles.

3. Table Movement

The table of a jig boring machine is designed to move in multiple directions to accurately position the workpiece. The table movement is controlled to achieve precise hole placement and alignment.

- X-Axis Movement: The table moves horizontally from left to right.

- Y-Axis Movement: The table moves horizontally from front to back.

- Z-Axis Movement: The table can also move vertically in some advanced machines.

4. Positioning and Alignment

One of the critical aspects of jig boring machines is their ability to precisely position and align the workpiece. This is achieved through precise control mechanisms and measurement systems. The machine is equipped with scales, micrometers, and digital readouts to ensure accurate positioning.

- Scales and Micrometers: Provide precise measurements for table and spindle movements.

- Digital Readouts: Display the exact position of the spindle and table, allowing for precise adjustments.

5. Cutting Tool

The cutting tool used in jig boring machines is typically a high-precision boring tool. The tool is mounted on the spindle and rotates to perform the drilling operation. The choice of cutting tool depends on the material of the workpiece and the required hole size.

- Boring Tool: Designed for precision drilling, ensuring accurate hole dimensions and smooth finishes.

6. Control System

The control system of a jig boring machine can be manual, semi-automatic, or fully automatic (CNC). The control system manages the movements of the spindle and table, ensuring precise execution of the drilling process.

- Manual Control: The operator manually adjusts the spindle and table movements.

- Semi-Automatic Control: Combines manual adjustments with automated features for increased precision.

- CNC Control: Uses computer programming to control the spindle and table movements, allowing for complex and automated machining tasks.

7. Precision Measurement

Precision measurement is a crucial aspect of jig boring machines. The machine is equipped with measurement systems to ensure the accuracy of the holes and alignment of the workpiece. This includes:

- Dial Indicators: Measure small deviations in position and alignment.

- Coordinate Measuring Machines (CMMs): Used to verify the accuracy of the machined parts.

8. Coolant System

To ensure smooth cutting and prolong the life of the cutting tool, jig boring machines are equipped with a coolant system. The coolant reduces heat generated during the drilling process and helps remove chips from the cutting area.

- Coolant Pump: Circulates the coolant to the cutting area.

- Coolant Nozzles: Direct the coolant flow to the cutting tool and workpiece.

The working principle of jig boring machines involves the precise movement of the spindle and table, accurate positioning and alignment of the workpiece, and the use of high-precision cutting tools. The machine’s robust structure, advanced control systems, and precision measurement tools ensure the creation of accurate holes and the precise alignment of components. By understanding these principles, operators can achieve optimal performance and accuracy in their machining tasks.

Types of Jig Boring Machines

Jig boring machines come in several types, each designed to meet specific requirements and operational conditions. The main types include:

- Vertical Jig Boring Machines

- Horizontal Jig Boring Machines

- CNC Jig Boring Machines

- Manual Jig Boring Machines

1. Vertical Jig Boring Machines

Design and Working Principle

Vertical jig boring machines have a vertically oriented spindle. The workpiece is fixed on the machine table, and the spindle moves vertically to create precise holes. The main components of a vertical jig boring machine include:

- Spindle: Moves vertically to create holes.

- Machine Table: Holds and positions the workpiece.

- Control System: Manages the movement of the spindle and table.

The vertical movement of the spindle, combined with the precise positioning of the workpiece, allows for high accuracy and repeatability.

Advantages

- High precision

- Suitable for creating deep holes

- Versatile and adaptable for various applications

Applications

- Aerospace component manufacturing

- Precision molds and dies

- Automotive part production

2. Horizontal Jig Boring Machines

Design and Working Principle

Horizontal jig boring machines have a horizontally oriented spindle. The workpiece is fixed on a table that can move in multiple directions. The main components of a horizontal jig boring machine include:

- Spindle: Moves horizontally to create holes.

- Machine Table: Holds and positions the workpiece.

- Control System: Manages the movement of the spindle and table.

The horizontal movement of the spindle, combined with the precise positioning of the workpiece, allows for the creation of holes in large and heavy workpieces.

Advantages

- High precision for large workpieces

- Suitable for horizontal hole creation

- Ideal for heavy-duty applications

Applications

- Large aerospace structures

- Heavy machinery components

- Precision engineering projects

3. CNC Jig Boring Machines

Design and Working Principle

CNC (Computer Numerical Control) jig boring machines are equipped with computerized control systems. They offer automated and precise control over the machining process. The main components of a CNC jig boring machine include:

- Spindle: Moves according to programmed instructions.

- Machine Table: Holds and positions the workpiece.

- CNC Control System: Manages the movement of the spindle and table based on programmed commands.

CNC jig boring machines offer high precision, repeatability, and automation, making them ideal for complex and high-volume production.

Advantages

- High precision and repeatability

- Automation reduces manual intervention

- Suitable for complex machining tasks

Applications

- Mass production of precision components

- Complex aerospace parts

- Medical device manufacturing

4. Manual Jig Boring Machines

Design and Working Principle

Manual jig boring machines require manual operation and control. The operator manually adjusts the spindle and table movements. The main components of a manual jig boring machine include:

- Spindle: Moves based on manual adjustments.

- Machine Table: Holds and positions the workpiece.

- Manual Controls: Allow the operator to manage the movement of the spindle and table.

Manual jig boring machines are suitable for low-volume production and prototyping, where flexibility and operator control are essential.

Advantages

- Flexibility for custom machining

- Ideal for low-volume production

- Suitable for prototyping and small-scale projects

Applications

- Custom machining projects

- Prototyping and R&D

- Small-scale production runs

Applications of Jig Boring Machines

Jig boring machines are versatile tools with a wide range of applications across various industries. Some common applications include:

1. Aerospace Component Manufacturing

In the aerospace industry, jig boring machines are used to create precise holes in components such as engine parts, airframe structures, and landing gear. The high accuracy of these machines ensures the proper fit and alignment of critical components.

2. Precision Molds and Dies

Jig boring machines are employed in the manufacturing of precision molds and dies used in plastic injection molding, die casting, and metal stamping. The accuracy of the holes ensures the proper functioning of the molds and dies, resulting in high-quality finished products.

3. Automotive Part Production

In the automotive industry, jig boring machines are used to produce precise holes in engine blocks, transmission components, and other critical parts. The high precision of these machines ensures the reliability and performance of automotive components.

4. Medical Device Manufacturing

The medical device industry relies on jig boring machines to create precise holes in components such as surgical instruments, implants, and diagnostic equipment. The accuracy of these machines ensures the proper fit and function of medical devices, contributing to patient safety and effectiveness.

Advantages of Using Jig Boring Machines

Jig boring machines offer several advantages that make them a preferred choice in precision machining:

- High Precision: Jig boring machines provide high accuracy and repeatability, ensuring precise hole placement and alignment.

- Versatility: They are adaptable to a wide range of applications, from aerospace and automotive to medical device manufacturing.

- Automation: CNC jig boring machines offer automation, reducing manual intervention and increasing efficiency.

- Flexibility: Manual jig boring machines provide flexibility for custom machining and prototyping.

- Durability: These machines are designed to withstand demanding environments and heavy use, ensuring long-term reliability.

Design Considerations for Jig Boring Machines

When selecting a jig boring machine, several factors must be considered to ensure optimal performance and efficiency:

- Type of Jig Boring Machine: Choose the appropriate type based on the specific application and required precision. Vertical, horizontal, CNC, and manual jig boring machines each have their advantages and are suited to different tasks.

- Spindle Speed and Power: Consider the required spindle speed and power based on the material to be machined and the desired accuracy.

- Workpiece Size and Weight: Evaluate the size and weight of the workpiece to ensure the machine can accommodate it.

- Control System: For CNC machines, assess the capabilities of the control system, including programming options and ease of use.

- Maintenance Requirements: Choose a machine that is easy to maintain and has readily available replacement parts.

Maintenance of Jig Boring Machines

Regular maintenance of jig boring machines is essential to ensure efficient operation and longevity. Here are some maintenance practices to follow:

- Inspection: Regularly inspect the machine for signs of wear, damage, and loose components. Check the spindle, table, and other critical parts.

- Cleaning: Keep the machine clean by removing dust, debris, and residues. This helps maintain optimal performance and prevents damage.

- Lubrication: Properly lubricate moving parts to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants.

- Calibration: Periodically calibrate the machine to ensure accuracy and precision. Check the alignment of the spindle and table.

- Safety Checks: Conduct regular safety checks, including inspecting safety features, testing emergency shutdown systems, and ensuring proper ventilation.

Conclusion

Jig boring machines are indispensable in precision machining, providing high accuracy and repeatability for creating precise holes and aligning components. Understanding the different types of jig boring machines and their specific applications helps in selecting the most suitable tool for any task.

Frequently Asked Questions About Jig Boring Machines

1. What is a jig boring machine used for?

A jig boring machine is used to create highly precise holes and ensure accurate alignment of components, essential in industries like aerospace, automotive, and manufacturing.

2. What is the difference between vertical and horizontal jig boring machines?

- Vertical Jig Boring Machines: Have a vertically oriented spindle, ideal for creating deep holes and versatile applications.

- Horizontal Jig Boring Machines: Have a horizontally oriented spindle, suitable for machining large and heavy workpieces and horizontal hole creation.

3. What is a jig milling machine?

A jig milling machine combines the features of a jig borer and a milling machine, performing both boring and milling operations with high precision, suitable for creating precise holes, slots, and intricate features.

4. What is the difference between a jig borer and a milling machine?

- Jig Borer: Designed for creating precise holes and accurate alignment, with high-precision measurement systems.

- Milling Machine: Versatile machine tool for various machining operations, including cutting, drilling, and shaping, but generally less precise than a jig borer.

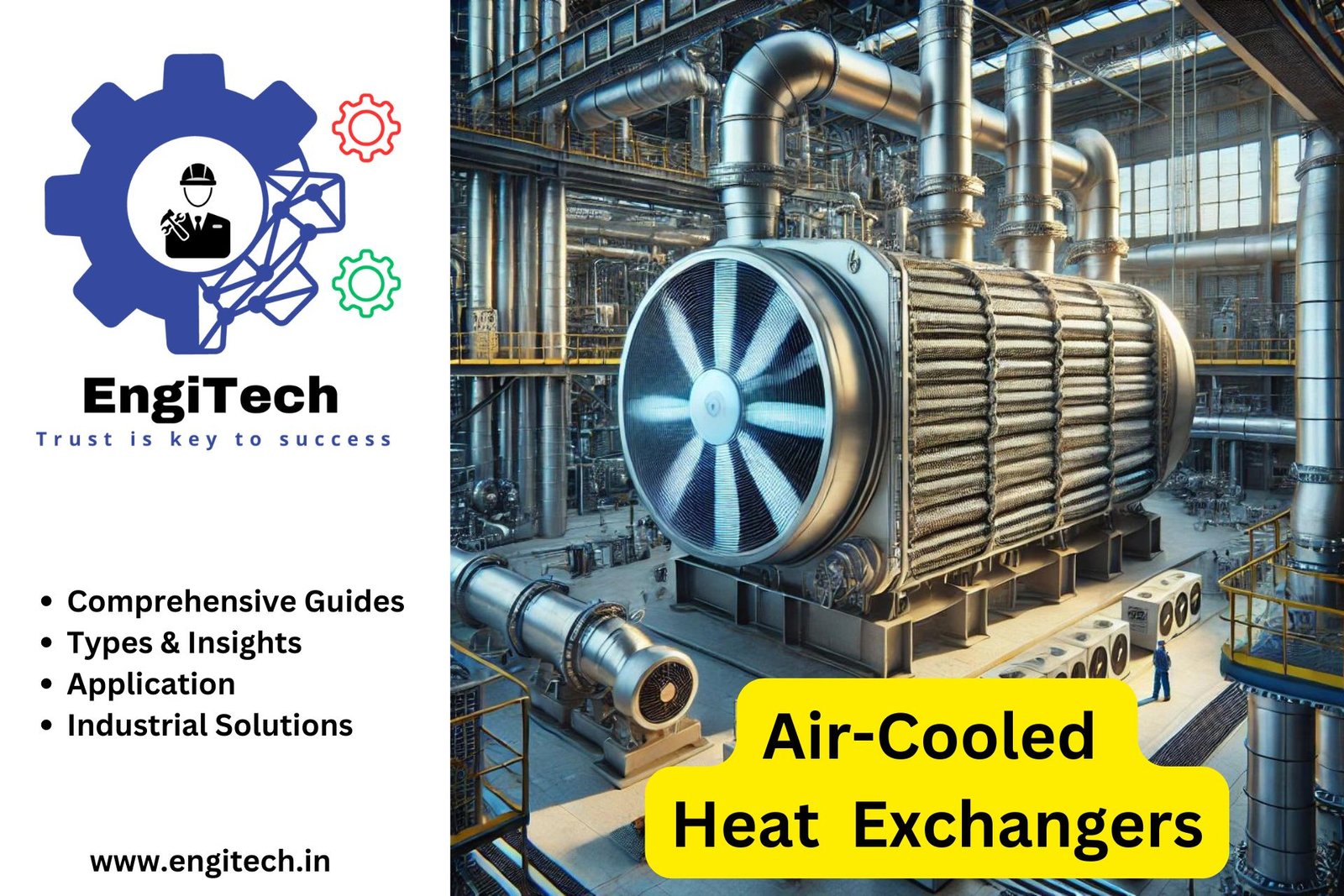

From Our Team

Welcome to EngiTech, the ultimate destination for cutting-edge industrial engineering tools and insights. Our platform offers comprehensive guides and the latest advancements in precision machining, including the powerful and versatile jig boring machines. We are committed to providing high-quality, detailed content that empowers professionals in the aerospace, automotive, and manufacturing industries.

Our expert team ensures you have access to the most accurate and actionable information to enhance your operations and achieve unparalleled precision. Trust EngiTech for all your industrial engineering needs and join a community dedicated to excellence and innovation. Visit us today and elevate your projects with the best in precision engineering technology.

Thank You !