In-Depth Guide to Emission Control Systems: Key Types and Benefits & more

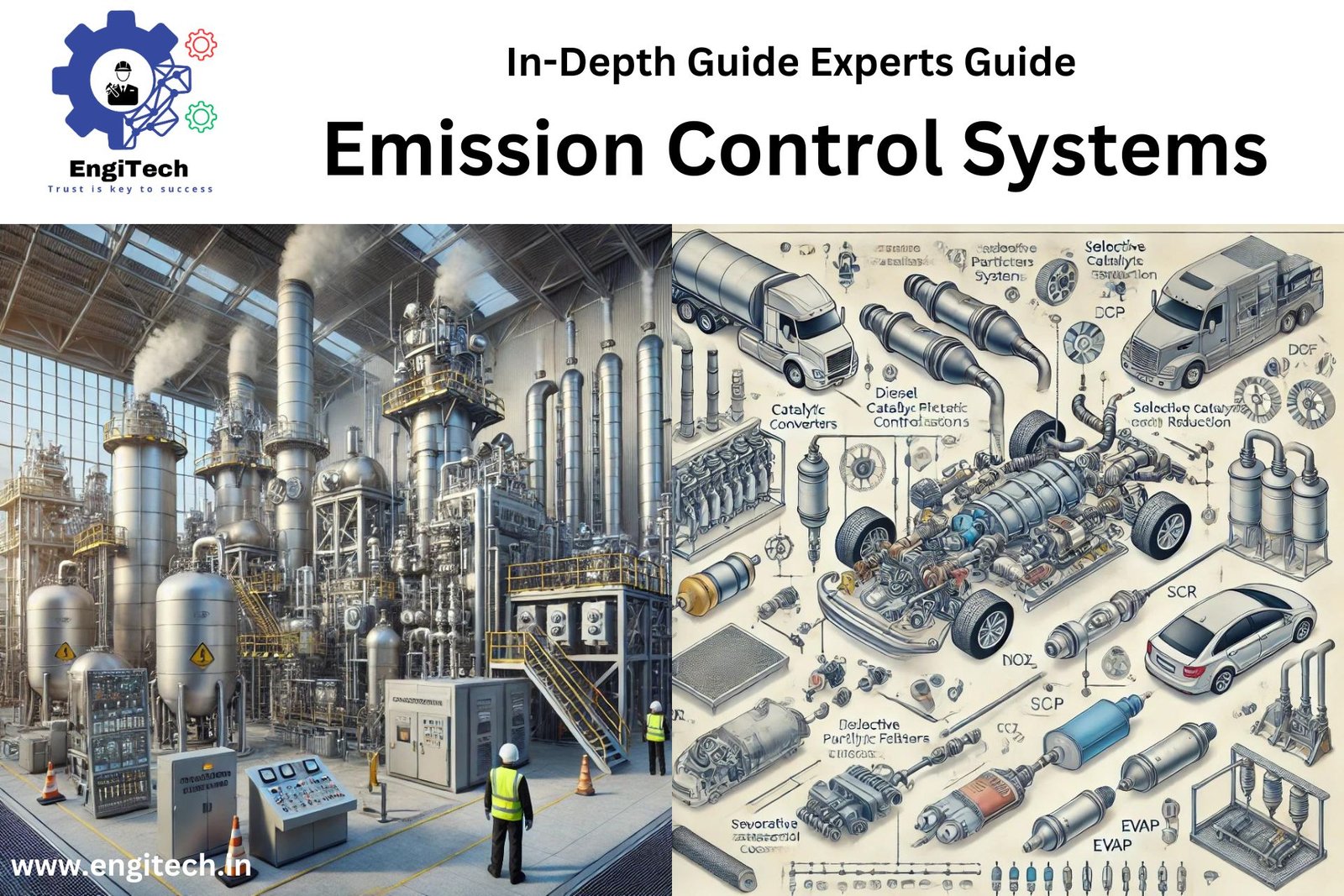

Did you know that a single passenger vehicle without proper emission controls can release over 4.6 metric tons of carbon dioxide annually? In an era where environmental sustainability has moved from optional to imperative, emission control systems have become the unsung heroes of our industrial and automotive landscapes. These sophisticated technologies silently work to capture harmful pollutants before they escape into our atmosphere, protecting both public health and our planet’s delicate ecosystems. Whether you’re an industry professional seeking compliance solutions, a vehicle owner wondering about your car’s environmental impact, or simply an environmentally conscious citizen, understanding emission control systems is more crucial than ever before.

This comprehensive guide will walk you through everything you need to know about emission control systems – from the fundamental science behind how they work to the cutting-edge technologies shaping their future. We’ll explore the various types of systems used across different industries, regulatory frameworks governing emissions worldwide, and practical maintenance tips to ensure your systems operate at peak efficiency. By the end of this article, you’ll have a thorough understanding of emission control systems and how they contribute to a cleaner, healthier world.

Table of Contents

What Are Emission Control Systems?

Emission control systems represent a diverse category of technologies designed to reduce or eliminate harmful substances released into the atmosphere during combustion and industrial processes. These systems play a crucial role in mitigating environmental pollution and meeting increasingly stringent regulatory standards across the globe.

The Science Behind Emissions

Before diving into control systems, it’s essential to understand what exactly we’re controlling. Emissions typically fall into several major categories:

- Particulate Matter (PM): Microscopic solid or liquid particles suspended in air, often produced by diesel engines, industrial processes, and combustion

- Nitrogen Oxides (NOx): Reactive gases formed during high-temperature combustion, contributing to smog and acid rain

- Carbon Monoxide (CO): An odorless, colorless gas produced by incomplete combustion of carbon-based fuels

- Hydrocarbons (HC): Organic compounds resulting from unburned fuel that contribute to ground-level ozone formation

- Sulfur Dioxide (SO2): A gas primarily released when burning sulfur-containing fuels like coal and oil

- Carbon Dioxide (CO2): While naturally present in the atmosphere, excessive CO2 from human activities is the primary greenhouse gas driving climate change

Each of these pollutants poses unique health and environmental risks, necessitating specialized control technologies tailored to specific emission profiles.

The Evolution of Emission Control Technology

Emission control technology has undergone a remarkable evolution over the past several decades, driven by increasing environmental awareness and regulatory pressure. What began as simple mechanical solutions has transformed into sophisticated systems integrating advanced materials science, precision engineering, and digital controls.

In the 1950s and 1960s, the first automotive emission control devices were basic positive crankcase ventilation (PCV) systems designed to reduce hydrocarbon emissions. By the 1970s, catalytic converters emerged as a revolutionary technology that could transform harmful gases into less harmful substances through chemical reactions.

Today’s emission control systems represent the culmination of decades of research and development, incorporating multiple technologies working in concert to achieve unprecedented levels of pollution reduction. Modern vehicles and industrial facilities utilize computer-controlled systems that continuously monitor and adjust emission control parameters for optimal performance.

Types of Emission Control Systems

Emission control technologies vary widely depending on their application, the pollutants targeted, and the regulatory requirements they must meet. Let’s explore the major categories and how they function.

Automotive Emission Control Systems

Modern vehicles incorporate several integrated systems to reduce harmful emissions:

Catalytic Converters

The catalytic converter remains one of the most important emission control devices in modern vehicles. Located within the exhaust system, these devices use precious metal catalysts (typically platinum, palladium, and rhodium) to trigger chemical reactions that convert harmful substances into benign ones:

- Carbon monoxide (CO) is converted to carbon dioxide (CO2)

- Hydrocarbons (HC) are converted to carbon dioxide and water

- Nitrogen oxides (NOx) are broken down into nitrogen and oxygen

Two main types exist:

- Two-way catalytic converters: Focus on oxidizing CO and HC into CO2 and water

- Three-way catalytic converters: Additionally reduce NOx emissions through a reduction process

Exhaust Gas Recirculation (EGR) Systems

EGR systems reduce NOx formation by recirculating a portion of exhaust gas back into the engine’s combustion chambers. This lowers combustion temperatures, which inhibits NOx formation. Modern EGR systems use precision electronic controls to optimize the amount of exhaust recirculated based on driving conditions.

Diesel Particulate Filters (DPF)

DPFs capture soot and particulate matter from diesel exhaust through a physical filtration process. As exhaust passes through the filter’s honeycomb structure, particulates become trapped while gases flow through. These systems periodically undergo “regeneration” cycles, burning accumulated particulates at high temperatures to clean the filter.

Selective Catalytic Reduction (SCR)

SCR systems use a liquid reducing agent (typically a urea-based solution known as diesel exhaust fluid or AdBlue) injected into the exhaust stream. When this solution reacts with NOx in the presence of a catalyst, it converts harmful nitrogen oxides into nitrogen and water vapor. SCR technology has enabled diesel engines to meet stringent emissions standards while maintaining fuel efficiency.

Evaporative Emission Control Systems

These systems prevent fuel vapors from escaping into the atmosphere. Components include:

- Charcoal canisters: Capture and store fuel vapors

- Purge valves: Release stored vapors back into the engine for combustion

- Sealed fuel systems: Prevent vapor leakage

Industrial Emission Control Systems

Industrial processes often generate unique emission profiles requiring specialized control technologies:

Electrostatic Precipitators (ESP)

ESPs use electrical forces to remove particulates from gas streams. The process involves:

- Charging particles in an electrical field

- Attracting charged particles to collection plates

- Periodically removing collected particulates

These systems are particularly effective for large industrial operations like power plants and cement factories, with collection efficiencies exceeding 99% for many applications.

Scrubbers

Scrubbers use liquid (usually water, sometimes with additives) to remove pollutants from gas streams. Two primary types exist:

- Wet scrubbers: Gas streams contact liquid directly, trapping soluble pollutants and particulates

- Dry scrubbers: Gaseous pollutants react with dry reagents (like lime) to form solid compounds that can be filtered out

These systems are particularly effective for removing acid gases like sulfur dioxide (SO2) and hydrogen chloride (HCl).

Thermal Oxidizers

Thermal oxidizers destroy volatile organic compounds (VOCs) and other combustible pollutants by heating them to high temperatures (1,300-1,800°F) in the presence of oxygen, converting them to carbon dioxide and water vapor. Variants include:

- Regenerative thermal oxidizers: Use heat transfer beds to recover and reuse thermal energy

- Catalytic oxidizers: Employ catalysts to lower the required operating temperature

Baghouses

Baghouse systems filter particulate matter from gas streams by passing them through fabric filter bags. As gas flows through the fabric, particles become trapped while clean gas passes through. These systems regularly clean themselves through pulse-jet, reverse-air, or shaker mechanisms that dislodge collected dust.

Carbon Adsorption Systems

These systems remove VOCs and other gaseous pollutants by passing them through beds of activated carbon. The microporous structure of activated carbon provides an enormous surface area that attracts and holds organic molecules through adsorption. Once saturated, the carbon can often be regenerated through heating or steam treatment.

Regulatory Framework for Emission Control

Emission control systems exist within a complex global regulatory landscape that continues to evolve toward more stringent standards. Understanding these regulations is crucial for compliance and environmental planning.

Global Emission Standards

While emission regulations vary by region, several frameworks have global influence:

Vehicle Emission Standards

- Euro Standards (Europe): Currently at Euro 6/VI, these tiered regulations limit emissions of NOx, PM, CO, and HC for passenger vehicles and heavy-duty engines

- Tier Standards (United States): The EPA’s Tier 3 standards integrate vehicle emissions and fuel standards for reduced pollution

- China National Standards: China’s rapidly evolving standards now closely align with Euro equivalents

- Bharat Stage (India): India implemented BS-VI (equivalent to Euro 6) nationwide in 2020

Industrial Emission Regulations

- Industrial Emissions Directive (EU): Requires use of Best Available Techniques (BAT) for pollution prevention

- Clean Air Act (US): Establishes National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS)

- Paris Agreement: Global framework for greenhouse gas emissions reduction

Compliance and Certification

Achieving regulatory compliance involves several key processes:

- Emissions Testing: Standardized procedures measure pollutant levels under controlled conditions

- Type Approval: Manufacturers must demonstrate that prototype vehicles or equipment meet applicable standards

- Conformity of Production: Ensuring mass-produced items match approved specifications

- In-Service Monitoring: Ongoing verification that systems maintain performance throughout their operational life

The Cost of Non-Compliance

Organizations failing to meet emission standards face significant consequences:

- Substantial financial penalties (often millions of dollars for serious violations)

- Product recalls and sales bans

- Criminal prosecution for egregious violations

- Reputational damage and consumer backlash

- Potential civil liability for environmental damage

The 2015 “Dieselgate” scandal, where certain manufacturers used defeat devices to manipulate emissions test results, resulted in billions in fines and settlements, demonstrating the severe consequences of circumventing emission regulations.

Best Practices for Emission Control System Maintenance

The effectiveness of emission control systems depends heavily on proper maintenance and operation. Following manufacturer-recommended practices ensures optimal performance and regulatory compliance.

For Automotive Systems

Vehicle owners should adhere to these maintenance guidelines:

- Regular Inspections: Follow manufacturer-recommended service intervals for emission system checks

- Oxygen Sensor Replacement: Replace oxygen sensors according to maintenance schedules (typically every 60,000-100,000 miles)

- Check Engine Light Response: Address check engine warnings promptly, as they often indicate emission system issues

- Catalytic Converter Care: Avoid damage from road debris and use appropriate fuels (lead-free gasoline)

- DPF Maintenance: For diesel vehicles, ensure proper DPF regeneration cycles and avoid excessive idling

- SCR System Care: Maintain adequate DEF levels and quality in vehicles with SCR systems

For Industrial Systems

Industrial facilities should implement comprehensive maintenance programs:

- Preventive Maintenance Schedules: Establish and follow regular inspection and service intervals

- Performance Monitoring: Continuously track key parameters to detect degradation before failures occur

- Staff Training: Ensure operators understand proper system operation and troubleshooting

- Spare Parts Management: Maintain inventory of critical components to minimize downtime

- Documentation: Keep detailed maintenance records for regulatory compliance and performance tracking

- Professional Service: Utilize qualified technicians for complex maintenance and repairs

Troubleshooting Common Issues

Recognizing and addressing common problems quickly can prevent more serious failures:

Automotive Systems

- Catalytic Converter Clogging: Symptoms include reduced power and poor fuel economy; causes include oil consumption and rich fuel mixture

- Oxygen Sensor Degradation: Results in poor engine performance and increased emissions; replace according to schedule

- EGR System Failures: Carbon buildup can cause sticking valves; professional cleaning may be required

- DPF Blockage: Incomplete regeneration cycles can lead to excessive back pressure; follow driving patterns that enable proper regeneration

Industrial Systems

- Reduced Collection Efficiency: May indicate component wear or system leaks

- Pressure Drop Changes: Abnormal readings often signal filter blockage or component damage

- Control System Errors: Electronic control issues require prompt diagnosis by qualified technicians

- Unexpected Emissions Spikes: Can indicate catalyst degradation or system bypass

Emerging Technologies in Emission Control

The field of emission control continues to evolve rapidly, with several promising technologies on the horizon:

Advanced Catalysts

Researchers are developing next-generation catalytic materials that:

- Function effectively at lower temperatures (addressing “cold start” emissions)

- Utilize reduced amounts of precious metals

- Demonstrate greater durability and resistance to poisoning

- Provide broader pollutant conversion capabilities

Zeolite-based catalysts and single-atom catalysts represent particularly promising developments, offering enhanced performance with reduced material costs.

Smart Emission Control Systems

Digital technologies are transforming emission control through:

- Predictive Controls: Using AI and machine learning to anticipate operating conditions and optimize system performance

- Real-Time Monitoring: Continuous emissions monitoring with wireless connectivity for immediate feedback

- Advanced Diagnostics: Self-diagnostic capabilities that detect issues before failures occur

- Over-the-Air Updates: Software improvements delivered remotely to enhance performance

Alternative Propulsion Technologies

While traditional emission control systems focus on cleaning exhaust from combustion engines, alternative propulsion technologies aim to eliminate harmful emissions at the source:

- Battery Electric Vehicles (BEVs): Produce zero tailpipe emissions, though lifecycle considerations include battery production and electricity generation

- Hydrogen Fuel Cells: Generate electricity through electrochemical reactions, emitting only water vapor

- Biofuels: Advanced sustainable biofuels can reduce net carbon emissions when accounting for carbon capture during feedstock growth

Carbon Capture Technologies

For applications where complete elimination of carbon emissions isn’t feasible, carbon capture technologies offer promising alternatives:

- Post-Combustion Capture: Removes CO2 from flue gases after combustion

- Pre-Combustion Capture: Processes fuel before combustion to separate carbon

- Oxy-Fuel Combustion: Burns fuel in pure oxygen for more efficient carbon capture

- Direct Air Capture: Extracts CO2 directly from ambient air

These technologies are particularly relevant for hard-to-decarbonize industries like cement production and steel manufacturing.

Economic Considerations of Emission Control

Implementing effective emission control systems involves complex economic considerations that extend beyond simple compliance costs.

Initial Investment vs. Long-Term Benefits

The upfront costs of emission control technologies can be substantial:

- Automotive Systems: Advanced emission controls add $2,000-$4,000 to vehicle production costs

- Industrial Systems: Large facilities may invest millions in comprehensive emission control infrastructure

However, these investments often yield significant long-term benefits:

- Regulatory Compliance: Avoiding fines and penalties

- Operational Efficiency: Many modern systems improve overall process efficiency

- Extended Equipment Life: Cleaner operation often translates to reduced wear

- Corporate Responsibility: Meeting environmental commitments and enhancing brand reputation

Return on Investment Calculations

Organizations evaluating emission control investments should consider:

- Compliance Requirements: Mandatory systems necessary for legal operation

- Energy Efficiency Gains: Potential reductions in fuel or electricity consumption

- Maintenance Costs: Ongoing service and replacement component expenses

- Operational Lifetime: Expected service duration before major overhauls or replacement

- Residual Value: Potential resale or recycling value at end-of-life

The most economically advantageous solutions often involve integrating emission controls during initial design rather than retrofitting existing systems, allowing for optimized integration and performance.

Emission Trading and Carbon Markets

Market-based mechanisms provide additional economic dimensions to emission control:

- Cap-and-Trade Systems: Allow facilities to buy and sell emission allowances, creating financial incentives for reductions

- Carbon Taxes: Direct fees on carbon emissions incentivize control technology investment

- Clean Development Mechanism: Enables emission reduction projects in developing countries to earn certified emission reduction credits

These mechanisms can transform emission control from a pure cost center to a potential source of value through careful management of emission profiles and credits.

Environmental and Health Impacts

The implementation of emission control systems yields significant environmental and health benefits that extend far beyond regulatory compliance.

Quantifiable Environmental Benefits

Effective emission control directly contributes to environmental protection through:

- Air Quality Improvement: Reduced ground-level ozone, particulate matter, and other pollutants

- Acid Rain Prevention: Lower sulfur dioxide and nitrogen oxide emissions reduce acidification of water bodies and soil

- Climate Change Mitigation: Reduced greenhouse gas emissions help limit global temperature increases

- Ecosystem Protection: Decreased pollution preserves biodiversity and habitat quality

Studies consistently demonstrate significant improvements in air quality in regions that implement rigorous emission standards. For example, the United States has seen a 77% reduction in aggregate emissions of six common pollutants since 1970, despite substantial increases in GDP, vehicle miles traveled, and energy consumption.

Public Health Implications

The health benefits of emission control are substantial and well-documented:

- Respiratory Disease Reduction: Lower rates of asthma, COPD, and other respiratory conditions

- Cardiovascular Health: Decreased incidence of heart disease linked to air pollution

- Cancer Risk Reduction: Reduced exposure to carcinogenic compounds

- Overall Mortality: Significant decreases in premature deaths attributable to air pollution

According to World Health Organization estimates, ambient air pollution contributes to approximately 4.2 million premature deaths worldwide annually, highlighting the critical importance of effective emission control systems.

Social Justice Dimensions

The distribution of emission sources and their impacts raises important environmental justice considerations:

- Disproportionate Exposure: Historically, pollution sources have been concentrated near disadvantaged communities

- Equitable Protection: Comprehensive emission controls help ensure all communities benefit from clean air policies

- Global Responsibility: Developed nations can support emission control implementation in developing regions

Effective emission control policies must address these dimensions to ensure environmental benefits are equitably distributed across all populations.

FAQ: Common Questions About Emission Control Systems

How long do automotive emission control systems typically last?

With proper maintenance, major components like catalytic converters typically last 100,000-150,000 miles. However, this varies significantly based on driving conditions, maintenance practices, and fuel quality. Oxygen sensors generally require replacement every 60,000-100,000 miles, while electronic components can last the vehicle’s lifetime unless damaged.

Do emission control systems reduce vehicle performance?

Modern emission control systems are designed to minimize performance impacts. While early systems from the 1970s often reduced power and efficiency, today’s integrated designs typically maintain performance while reducing emissions. In fact, many technologies like direct injection and turbocharging improve both performance and emissions simultaneously.

What happens if I remove emission control components from my vehicle?

Removing or disabling emission control components is:

- Illegal in most jurisdictions with significant penalties

- Potentially harmful to engine performance and longevity

- Detrimental to air quality and public health

- Likely to cause inspection failures and registration issues

Modern engines are designed to operate with their emission systems intact, and removal often triggers check engine lights and performance issues.

How are emissions measured and monitored?

Emissions are measured through several methods:

- Laboratory Testing: Standardized dynamometer tests for new vehicle certification

- Portable Emission Measurement Systems (PEMS): Real-world testing during actual operation

- Continuous Emission Monitoring Systems (CEMS): Fixed monitoring of industrial stacks

- Periodic Inspections: Regular testing at vehicle inspection stations

- Remote Sensing: Roadside systems that measure emissions as vehicles pass

Monitoring technology continues to advance, with increasing focus on real-world performance rather than laboratory conditions alone.

What’s the difference between Euro 6 and Tier 3 emission standards?

While both represent stringent modern standards, key differences include:

- Measurement Methods: Euro standards use grams per kilometer; Tier standards use grams per mile

- Durability Requirements: Different useful life assumptions

- Pollutant Focus: Slightly different emphasis on specific pollutants

- Implementation Timing: Different phase-in schedules

Despite these differences, both standards require sophisticated emission control technologies and represent significant reductions from previous generations of requirements.

Conclusion: The Future of Emission Control

As we navigate the complex challenges of climate change and environmental protection, emission control systems will continue to play a vital role in our technological landscape. The future promises even more sophisticated approaches that balance environmental responsibility with economic practicality.

The trajectory of emission control technology points toward increasingly integrated systems that address multiple pollutants simultaneously while enhancing overall efficiency. We can expect continued innovation in catalysts, filtration media, and control algorithms that push the boundaries of what’s possible in pollution reduction.

Perhaps most significantly, we’re witnessing a fundamental shift from end-of-pipe treatment to source reduction and alternative technologies that inherently produce fewer emissions. The growth of electrification across multiple sectors exemplifies this transition, promising a future where many current emission control challenges become obsolete.

For individual consumers and businesses alike, understanding emission control systems is no longer optional—it’s an essential aspect of environmental citizenship and regulatory compliance. By maintaining existing systems properly and embracing emerging technologies, we all contribute to the vital goal of cleaner air and a healthier planet.

Whether you’re a vehicle owner ensuring your catalytic converter functions properly, an industrial facility manager optimizing your emissions profile, or simply a citizen concerned about air quality, your engagement with emission control systems matters. The cumulative impact of these technologies across millions of applications worldwide represents one of humanity’s most successful environmental protection efforts.

Further Reading and References

For those seeking additional information on emission control systems, the following resources provide valuable insights:

- Environmental Protection Agency (EPA) – Vehicle Emissions

- European Environment Agency – Air Quality Standards

- International Council on Clean Transportation – Global Emission Standards

- Society of Automotive Engineers (SAE) – Technical Papers on Emission Control

- American Lung Association – State of the Air Report

- World Health Organization – Air Quality Guidelines

- Manufacturers of Emission Controls Association – Technical Resources

- Journal of the Air & Waste Management Association – Research Articles

- California Air Resources Board – Vehicles and Pollution

- United Nations Environment Programme – Air Quality Monitoring

Conclusion

Emission control systems are vital for reducing the environmental impact of vehicles and industrial processes. Understanding these systems, their components, and applications will help you make informed decisions, ensuring optimal performance and compliance with environmental regulations. Whether you’re in the automotive, power generation, manufacturing, or agricultural sector, investing in effective emission control systems will improve air quality, protect public health, and contribute to a sustainable future.

For more detailed information and resources on emission control systems, visit EngiTech. Stay informed about the latest advancements and best practices in emission control technology!