Expert Guide to Industrial Boilers: Electric and Steam Systems

Industrial boilers play a crucial role in various industries, providing the necessary steam and heat for manufacturing processes, power generation, and other applications. This guide will provide an in-depth look at industrial boilers, including electric boilers for industrial use and industrial steam boilers. We will cover their working principles, applications, advantages, and considerations for selecting the right boiler for your needs.

Understanding Industrial Boilers

Industrial boilers are large-scale systems designed to generate steam or hot water for industrial processes. They are essential in various sectors, including food processing, chemical manufacturing, power plants, and more. These boilers can be powered by different energy sources, including natural gas, oil, coal, and electricity.

Electric Boilers for Industrial Use

What is an Electric Boiler?

An electric boiler uses electricity to generate heat and produce steam or hot water. These boilers are highly efficient and environmentally friendly since they do not produce emissions during operation. Electric boilers are ideal for applications where natural gas or oil is not available or where emissions regulations are strict.

How Electric Boilers Work

Electric boilers operate using resistance heating elements that convert electrical energy into heat. This heat is then transferred to water, producing steam or hot water. The process is simple and efficient, with minimal heat loss.

- Heating Elements: Electric boilers use heating elements submerged in water to generate heat.

- Control System: A control system regulates the temperature and pressure within the boiler.

- Safety Features: Electric boilers include safety features such as pressure relief valves and temperature sensors to prevent overheating and overpressure.

Advantages of Electric Boilers

- High Efficiency: Electric boilers convert nearly 100% of the electrical energy into heat.

- Environmentally Friendly: They do not produce emissions, making them suitable for areas with strict environmental regulations.

- Compact Design: Electric boilers are typically smaller and more compact than other types of boilers, saving space in industrial settings.

- Low Maintenance: With fewer moving parts and no combustion process, electric boilers require less maintenance than gas or oil boilers.

Applications of Electric Boilers in Industry

Electric boilers are used in various industrial applications, including:

- Food Processing: For pasteurization, sterilization, and cooking processes.

- Chemical Manufacturing: Providing steam for chemical reactions and distillation processes.

- Pharmaceuticals: For sterilizing equipment and preparing ingredients.

- Power Generation: Supporting renewable energy systems and backup power supply.

Industrial Steam Boilers

What is an Industrial Steam Boiler?

An industrial steam boiler generates steam for various industrial processes. Steam is essential in many industries for heating, power generation, and mechanical work. Industrial steam boilers can be powered by natural gas, oil, coal, biomass, or electricity.

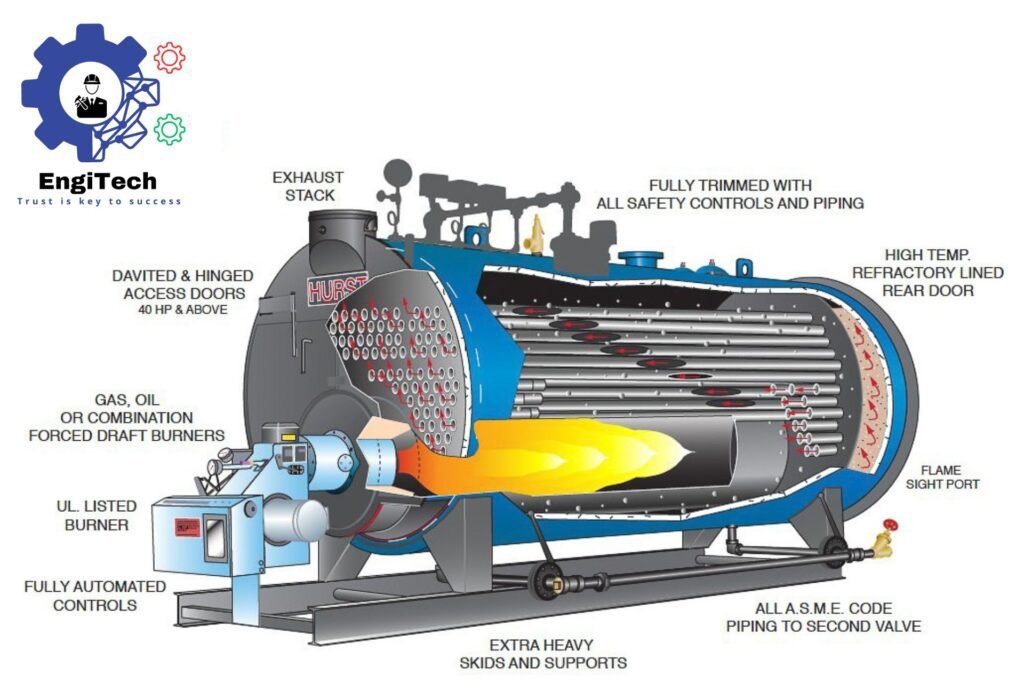

How Industrial Steam Boilers Work

Industrial steam boilers operate by heating water to produce steam. The steam is then used for heating, power generation, or other industrial processes.

- Combustion Chamber: Fuel burns in the combustion chamber to generate heat.

- Heat Exchanger: The heat transfers to water in the heat exchanger, producing steam.

- Steam Drum: The steam drum collects and distributes the steam.

- Control System: A control system regulates the temperature, pressure, and fuel supply.

Types of Industrial Steam Boilers

- Fire Tube Boilers: Hot gases pass through tubes surrounded by water, transferring heat to the water.

- Water Tube Boilers: Water flows through tubes heated by combustion gases, producing steam.

- Electric Steam Boilers: Use electric heating elements to generate steam without combustion.

Advantages of Industrial Steam Boilers

- High Efficiency: Modern steam boilers are highly efficient, reducing fuel consumption and operational costs.

- Versatility: Steam boilers can use various fuel sources, including renewable fuels like biomass.

- Scalability: Industrial steam boilers are available in different sizes and capacities to meet varying industrial needs.

- Reliability: Industrial steam boilers are designed for continuous operation, providing a reliable source of steam.

Applications of Industrial Steam Boilers

Industrial steam boilers are used in a wide range of applications:

- Power Generation: Producing electricity in power plants.

- Food and Beverage: For sterilization, cooking, and pasteurization.

- Chemical Processing: Providing heat and steam for chemical reactions.

- Textile Industry: For dyeing, drying, and fabric finishing.

- Paper and Pulp: Producing steam for the paper-making process.

Key Considerations for Choosing an Industrial Boiler

When selecting an industrial boiler, consider the following factors:

- Fuel Type: Choose a boiler that uses a readily available and cost-effective fuel source.

- Efficiency: Look for high-efficiency boilers to reduce operational costs and environmental impact.

- Capacity: Ensure the boiler has the capacity to meet your steam or hot water requirements.

- Maintenance: Consider the maintenance requirements and costs associated with the boiler.

- Regulations: Ensure the boiler complies with local emissions and safety regulations.

Maintaining Industrial Boilers

Regular maintenance is crucial for the safe and efficient operation of industrial boilers:

- Routine Inspections: Regularly inspect the boiler for signs of wear, leaks, and corrosion.

- Cleaning: Clean the combustion chamber, heat exchanger, and other components to maintain efficiency.

- Testing: Test safety valves, pressure gauges, and control systems to ensure they are functioning correctly.

- Repairs: Address any issues promptly to prevent breakdowns and extend the boiler’s lifespan.

Conclusion

Industrial boilers, including electric boilers and industrial steam boilers, are essential for various industrial processes. Understanding their working principles, advantages, and applications can help you choose the right boiler for your needs. Regular maintenance ensures safe and efficient operation, maximizing the boiler’s lifespan and performance.

For more detailed articles and resources on industrial boilers and related technologies, visit EngiTech.in. Stay updated on the latest advancements and best practices in the field!